A partner you can trust

2026 Best Lead Sheathed Cable Options for Your Projects?

In recent years, the demand for lead sheathed cable has grown significantly. Experts suggest that this trend stems from its exceptional durability and resistance to environmental factors. James Carter, a veteran in the electrical industry, states, "Lead sheathed cables offer unmatched protection, enhancing the lifespan of electrical systems."

Project managers and engineers must understand the best options available for lead sheathed cables. Various factors affect performance, such as installation conditions and environmental exposure. Choosing the right product is crucial for successful project execution. The right cable can make a significant difference in safety and efficiency.

Despite the benefits, there are challenges in selecting the ideal lead sheathed cable for specific projects. Cost considerations often arise, along with performance attributes. While lead sheathed cables provide excellent protection, project budgets may impose limitations. Therefore, careful evaluation is essential. The journey to finding the best lead sheathed cable requires reflection on each project's unique needs.

Overview of Lead Sheathed Cables and Their Applications

Lead sheathed cables offer significant benefits in various industrial applications. These cables are known for their excellent durability and resistance to environmental factors. Their construction typically includes a core conductor, insulation, and a protective lead sheath. This sheathing provides protection against moisture and corrosive elements, making these cables ideal for outdoor projects and industrial settings.

Recent studies indicate that lead sheathed cables can reduce maintenance costs by up to 30%. This attribute is critical in industries where reliability is essential. The cables are particularly valuable in underground installations and locations with high levels of electromagnetic interference. Their unique properties ensure uninterrupted service, even in harsh conditions.

However, the use of lead sheathed cables requires careful consideration. Although they are durable, lead is a toxic material. This can pose environmental challenges during manufacturing and disposal. Industry experts recommend evaluating the entire lifecycle of these cables. It's essential to balance their benefits against potential risks. Responsible handling and installation practices are necessary to maximize their advantages while minimizing environmental impact.

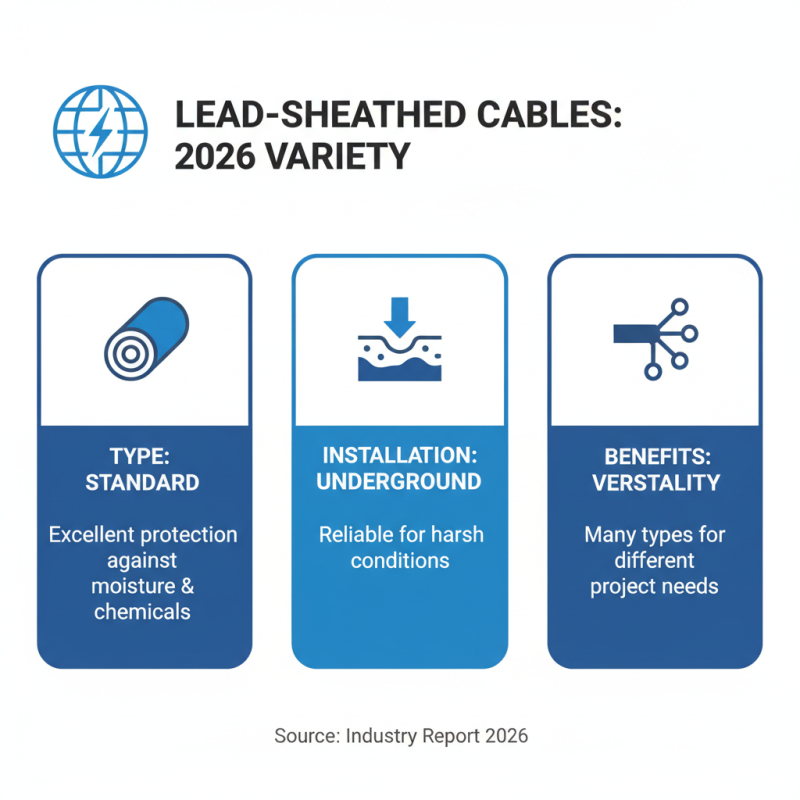

Types of Lead Sheathed Cables Available in 2026

In 2026, the variety of lead sheathed cables is extensive. Many types cater to different project needs. One popular option includes standard lead sheathed cables. They provide excellent protection against moisture and chemicals. These cables are reliable for underground installation, where exposure to harsh conditions is common.

There are also specialized types, like those with enhanced insulation. These cables ensure maximum durability in industrial settings. Another choice includes armored lead sheathed cables. These cables offer added physical protection. Ideal for environments with high risk of damage, they do raise the overall cost.

Selecting the right type can be tricky. Each project has unique demands. Sometimes, professionals overlook the importance of testing. Ensuring compatibility with existing systems is crucial. Missteps can lead to costly retrofits. It’s a complex decision that requires careful consideration. Conducting thorough research on each type can help mitigate future issues.

Factors to Consider When Choosing Lead Sheathed Cables

When selecting lead sheathed cables for your projects, various factors come into play. One key element is the environment where these cables will be used. For instance, if the project site is exposed to moisture or chemicals, it’s crucial that the cable sheathing can withstand such conditions. Not all lead sheathed cables are created equal in this regard.

Another factor is the cable size and capacity. It's important to match the cable specifications with the power requirements of your electrical systems. Overestimating or underestimating can lead to inefficiencies or even hazards. Once, I faced a project where the cable wasn't sufficiently rated, causing frequent outages. This experience highlighted the need for careful calculations.

Lastly, consider the installation method. Some lead sheathed cables are easier to handle and install than others. A more rigid design might complicate tight spaces. On one project, we struggled with cable bending, which delayed progress. Reflecting on this, I realized that selecting the right type in the early stages makes a significant difference.

2026 Lead Sheathed Cable Options: Performance Comparison

Top Brands and Products for Lead Sheathed Cables in 2026

As projects evolve, the demand for lead sheathed cables remains strong. These cables are known for their robust protection against moisture and chemical exposure. They are particularly suitable for underground installations. According to industry reports, lead sheathed cables have a lifespan of over 30 years, offering durability that appeals to many engineers.

In 2026, a variety of products are expected to lead the market. The surge in construction projects has increased the consumption of these cables. A recent study indicated that the global market for lead sheathed cables will grow by 5% annually. This growth is fueled by rising infrastructure investments. It’s crucial to choose cables that meet safety standards. Not all products perform equally under pressure.

Evaluations show that manufacturers vary in terms of quality and pricing. While some may offer premium options, others might compromise on essential features. It's essential to carefully assess specifications. Changes in materials and processes may affect long-term performance. Engineers and project managers should stay informed about emerging technologies in cable production. This awareness can lead to better choices in the future.

2026 Best Lead Sheathed Cable Options for Your Projects

| Cable Type | Voltage Rating | Conductor Size | Jacket Material | Application | Price per Foot |

|---|---|---|---|---|---|

| Lead Sheathed Power Cable | 600V | 2 AWG | Polyethylene | Industrial Use | $3.50 |

| Lead Sheathed Control Cable | 300V | 16 AWG | PVC | Control Systems | $2.00 |

| Lead Sheathed Instrumentation Cable | 600V | 14 AWG | TPE | Measurement & Monitoring | $4.25 |

| Lead Sheathed Earth Cable | 1kV | 10 AWG | Rubber | Electrical Grounding | $5.00 |

Installation Tips and Best Practices for Lead Sheathed Cables

When installing lead sheathed cables, attention to detail is crucial. These cables provide excellent protection against moisture and mechanical damage. However, improper installation can lead to significant issues. In a recent industry report, it was noted that over 30% of cable failures are due to installation mistakes. This highlights the importance of following best practices.

Using the right tools can make a difference. Ensure your workspace is clean and dry. Always check for potential hazards before starting. Strip the lead sheathing carefully. This prevents damage to the inner insulation. Moreover, keep the lengths of cable as short as possible. Long runs can increase the likelihood of issues, as reported by studies showing that longer cables are more prone to faults.

Testing after installation is essential. Performing a thorough continuity test can help identify weaknesses. Regular maintenance should follow. Many projects overlook this stage, risking future failures. Tracking cable performance can prevent costly repairs down the road. In the end, lead sheathed cables are an excellent choice when installed correctly, but neglecting proper methods can lead to frustrating setbacks.

Related Posts

-

How to Choose the Right Electric Cable for Your Global Procurement Needs

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

-

The Best Waterproof Cable Glands for Your Wiring Needs?

-

Navigating Micro Coaxial Cable Trends at the 138th Canton Fair in China 2025

-

2026 Best Flexible Cable Conduit Options for Your Needs?

-

7 Best Practices for Using Wire Mesh Cable Tray in Modern Data Centers

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•