A partner you can trust

2026 Top Wire Mesh Cable Tray Benefits and Uses Explained?

In recent years, wire mesh cable trays have gained significant traction in various industries. According to a report by MarketsandMarkets, the global cable tray market is expected to reach $4.5 billion by 2026, with wire mesh styles leading this growth. These trays offer a lightweight, durable solution for managing cables in commercial and industrial environments.

Wire mesh cable trays are designed to support and protect electrical cabling efficiently. Their open design allows for better air circulation, which can mitigate heat buildup and prolong cable life. Additionally, these trays are often made from corrosion-resistant materials, ensuring longevity in diverse settings.

However, some companies may overlook their installation needs. A poorly installed wire mesh cable tray can lead to cable damage or safety hazards. It’s essential to follow best practices and industry standards to ensure effectiveness. Understanding the benefits and appropriate applications of wire mesh cable trays can lead to significant cost savings and enhanced safety in the long term.

Benefits of Wire Mesh Cable Trays in Industrial Applications

Wire mesh cable trays offer versatile solutions for industrial applications. They provide excellent support for electrical cables, ensuring organized routing. This design minimizes the risk of damage and makes maintenance easier. The open structure allows for airflow, reducing heat buildup. This is crucial in facilities with high equipment loads.

Another advantage is their lightweight nature. They are easier to install compared to traditional solid trays. However, this can lead to concerns about durability. Proper installation is essential to ensure they can bear the weight of heavy cables. Without proper support, sagging may occur.

Wire mesh trays also promote safety. Their design helps in identifying issues with the cabling quickly. However, they may not be suitable for all environments, like areas exposed to corrosive substances. Choosing the right materials is important for long-term reliability. Each application requires careful consideration of these factors.

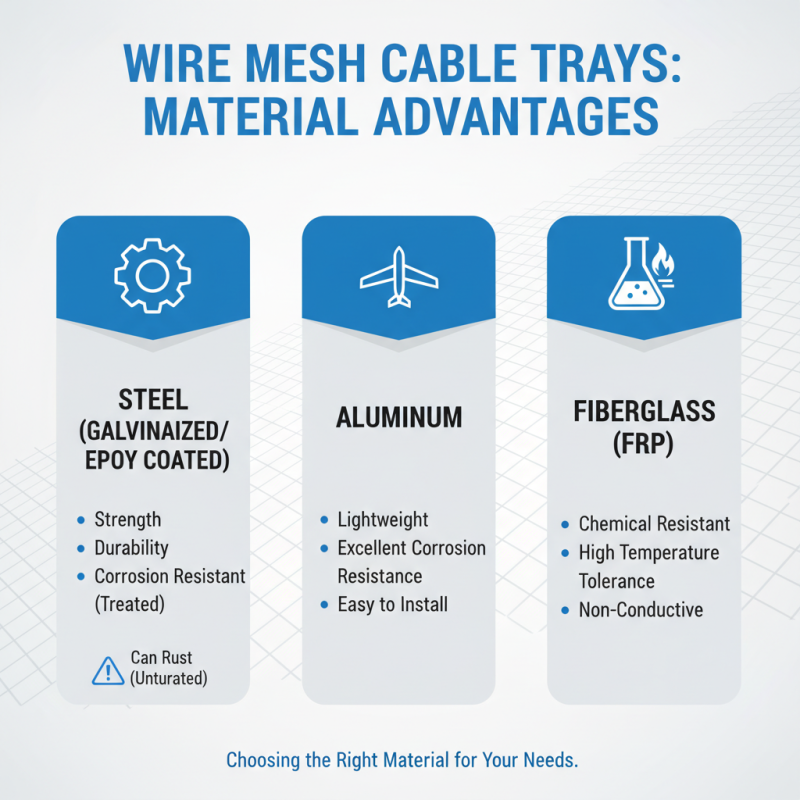

Overview of Materials Used in Wire Mesh Cable Tray Manufacturing

Wire mesh cable trays are becoming more popular due to their advantages. They are mainly made from materials like steel, aluminum, and fiberglass. Each material has unique benefits, catering to different needs. Steel is strong but can rust if not treated properly. Aluminum is lightweight and resistant to corrosion. Fiberglass, while less common, offers excellent resistance to chemicals and high temperatures.

Manufacturers often choose materials based on the project’s requirements. Weight load, environmental exposure, and cost are crucial factors. For instance, in humid locations, aluminum might be preferred over steel to prevent rust. The choice of material impacts the overall durability of the cable trays. Careful selection is vital for ensuring long-lasting performance.

Some companies overlook these factors in their projects. This can lead to increased maintenance costs later. The right wire mesh cable tray can significantly reduce issues like sagging or bending. In the end, material selection is more than just a choice; it requires thoughtful consideration of many variables.

Cost Efficiency of Wire Mesh Cable Trays Compared to Traditional Systems

Wire mesh cable trays have become increasingly popular in recent years. They offer a modern approach to cable management, especially in industrial settings. One significant advantage is their cost efficiency. Compared to traditional cable systems, they often require less material and installation time. This translates into lower labor costs and faster project completion.

One notable benefit is the lightweight design, which doesn’t compromise strength. They are easier to transport and handle. This efficiency can save considerable time on larger projects. It's also worth noting that maintenance is generally simpler. Accessing cables in a wire mesh tray is easier than in solid trays. Routine checks are less time-consuming, making upkeep straightforward.

Tips: Always assess your project’s needs before choosing a tray. Consider installation environments and potential future expansions. Be mindful of potential limitations with support spans. Ensure your team is trained on the proper handling of wire mesh systems. This foresight can prevent costly delays and safety issues.

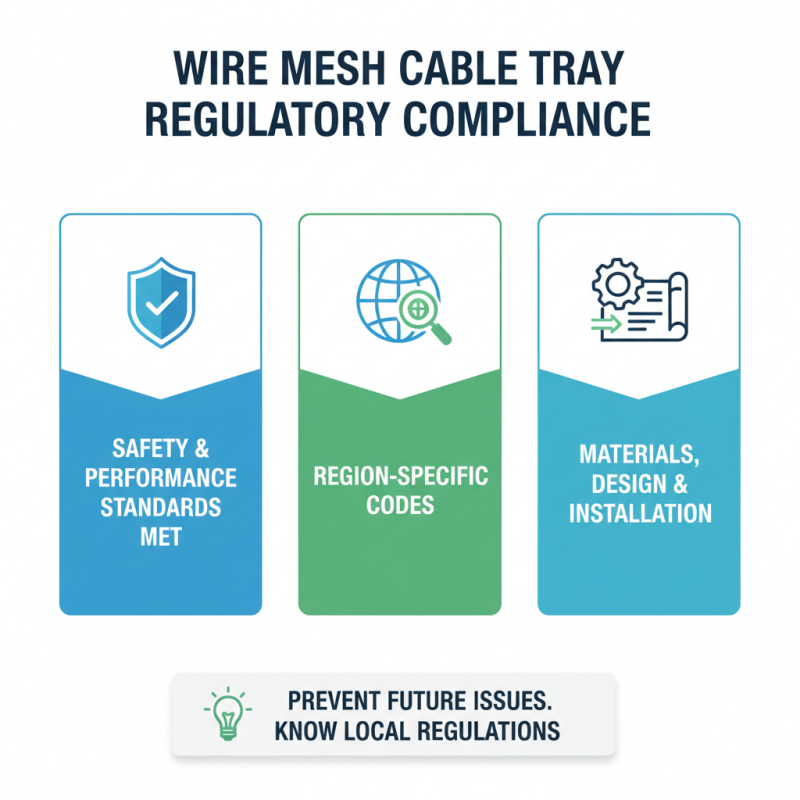

Regulatory Compliance and Safety Standards for Cable Tray Installations

When installing wire mesh cable trays, regulatory compliance is crucial. It ensures that the installation meets safety and performance standards. Each region has specific codes. These codes govern materials, design, and installation processes. Understanding local regulations prevents issues later.

Safety standards are not just guidelines; they protect people. Proper cable tray installation minimizes fire hazards and electrical risks. For instance, using appropriate materials reduces the chances of corrosion. Furthermore, ensuring correct weight distribution prevents collapses. Following best practices enhances overall system reliability.

However, compliance can be challenging. Many installers overlook local codes, which is a mistake. Regular training can help address this knowledge gap. Continuous education keeps everyone informed about updates. Ultimately, prioritizing safety and compliance is a shared responsibility. It requires commitment from all parties involved.

Installation and Maintenance Best Practices for Wire Mesh Cable Trays

Wire mesh cable trays are gaining popularity due to their versatility and durability. However, proper installation and maintenance are crucial for their long-term performance. According to industry reports, incorrect installation can lead to significant issues, such as equipment damage and reduced safety. It's essential to follow best practices for effective installation. For example, ensure trays are securely mounted, with adequate support spacing. Spacing should typically be no more than 10 feet apart to prevent sagging.

Maintenance is equally important. Regular inspections help identify wear and tear. Experts suggest checking connections and fasteners every six months. Dust or debris accumulation can compromise performance. Utilizing a vacuum or air compressor for cleaning can enhance lifespan. Furthermore, using corrosion-resistant coatings is advisable in harsh environments. Many facilities overlook this step, thinking it’s optional. Neglecting these practices can lead to costly repairs and downtime.

Lastly, seek feedback from installation teams. Communication may reveal recurring issues that need addressing. Adapting to these insights can optimize future projects. While wire mesh trays are efficient, they require careful attention. Balancing installation practices and ongoing maintenance ensures functionality and safety.

Benefits and Uses of Wire Mesh Cable Trays in 2026

Related Posts

-

7 Best Practices for Using Wire Mesh Cable Tray in Modern Data Centers

-

Top 5 Wire Cable Types for Efficient Connectivity and Enhanced Performance

-

Exploring Cooker Cable Innovations at the 2025 China Import and Export Fair

-

2025 Top Underground Cable Conduit Types: What You Need to Know

-

8 Essential Tips for Choosing the Best Outdoor Electrical Cable for Your Next Project

-

Top Power Extension Cables to Buy in 2025 for Home and Office Use

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•