A partner you can trust

What is Armoured Electrical Cable and Its Benefits?

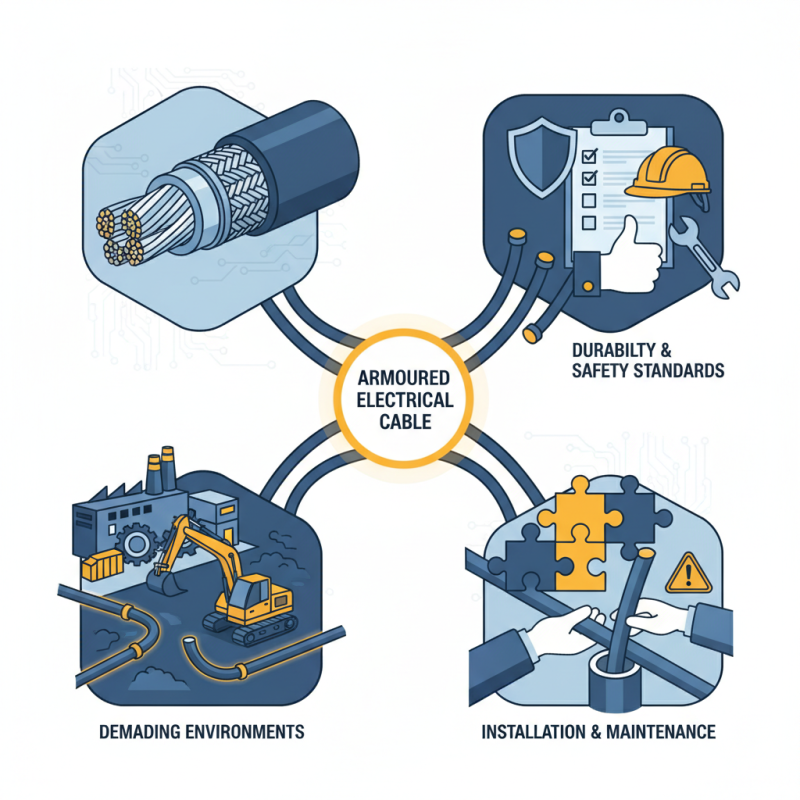

Armoured electrical cable is essential for many industries. Its robust design protects against physical damage. According to industry expert John Smith, "Armoured cables provide durability in demanding environments." This highlights their importance.

In construction and manufacturing, these cables resist impacts and abrasion. They are often used underground or in hazardous areas. However, not all armoured cables are created equal. The choice of material and design can impact performance.

While armoured electrical cables solve many problems, they are not foolproof. Installation can be complex. Maintaining them also requires careful attention. Users must reflect on proper usage and ensure they meet safety standards. Understanding these aspects is crucial for their overall effectiveness.

What is Armoured Electrical Cable?

Armoured electrical cable is a type of cable designed with protective layers to prevent damage. This cable is widely used in various applications, providing durability in harsh environments. It features steel or aluminum armouring, making it resistant to mechanical impact and external pressures. According to a recent industry report, the global demand for armoured cables is projected to grow significantly, driven by infrastructure development.

These cables are essential in construction sites, outdoor installations, and industrial zones. They safely transmit power to equipment and buildings while minimizing the risk of electrical faults. The use of armoured cables can reduce maintenance costs. Proper installation can lead to longer lifespan compared to standard cables.

Tips: Always check local regulations before installation. Inspect regularly for any signs of damage.

Armoured cables are not completely foolproof. Improper handling during installation can lead to potential failures. Additionally, they tend to be heavier and less flexible. It’s crucial to assess the specific needs of your project beforehand. Balancing safety and practicality is key.

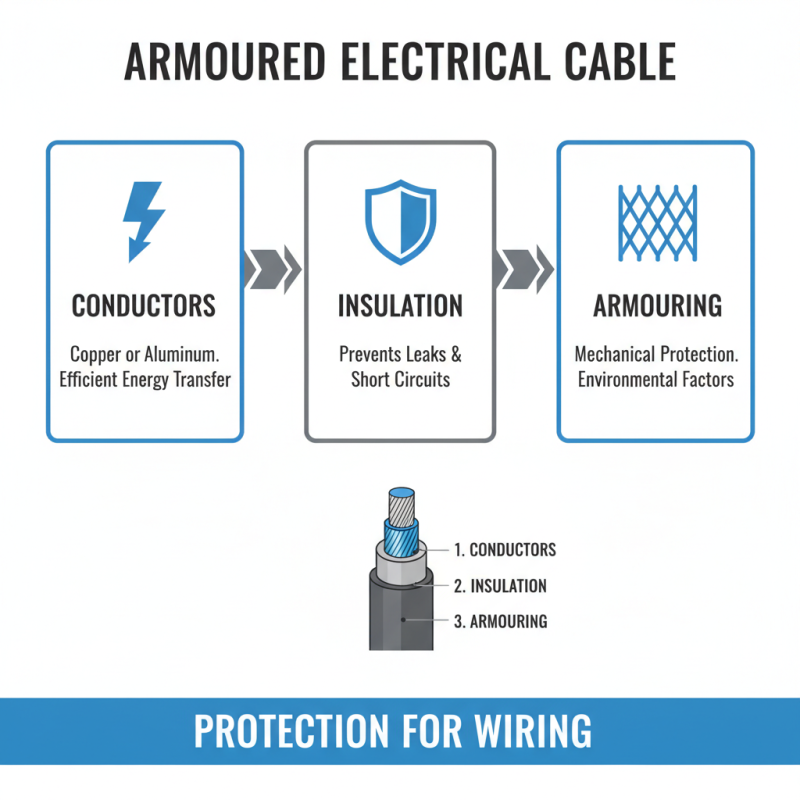

Key Components of Armoured Electrical Cable

Armoured electrical cable is designed to protect electrical wiring from mechanical damage and environmental factors. The key components of this type of cable include conductors, insulation, and the armouring itself. Conductors are typically made from copper or aluminium, ensuring efficient energy transfer. Insulation encases the conductors, preventing electrical leaks and short circuits.

The armouring consists of layers that shield the cable from impact and corrosion. This may include steel wires or other durable materials. Not everyone understands the necessity of armouring. It may seem like an added expense, but it is vital for certain installations. For example, in industrial settings, cables face constant hazards. The armoured design allows for safer operation in challenging conditions.

While the benefits of armoured cables are clear, some may overlook them. A lack of awareness can lead to poor decision-making in installations. Choosing the right cable depends on understanding the environment. Ignoring such details can result in higher costs and safety risks down the line. A reflective approach to selecting materials often yields better, safer results.

Advantages of Using Armoured Electrical Cables

Armoured electrical cables are essential for various applications. These cables have a protective outer layer made of metal. This layer helps prevent damage from external factors. In places like construction sites, armoured cables are crucial. They resist impacts and abrasions effectively.

Using armoured cables has numerous advantages. They offer excellent protection against environmental hazards. This ensures longevity and reliability in various conditions. The risk of electrical faults decreases significantly. Additionally, their robust design makes installation easier in rugged areas. Yet, it is vital to remember that armoured cables can be heavier and more rigid. This can create challenges during installation.

Armoured electrical cables also have benefits for safety. Their ability to withstand physical stress adds a layer of protection. This means fewer accidents and less downtime. However, the initial cost might be higher than standard cables. Some may hesitate to invest upfront. But, the long-term benefits often justify the expense. Choosing the right cable is crucial. Consider the specific environment and requirements before making a decision.

Advantages of Using Armoured Electrical Cables

Applications of Armoured Electrical Cables

Armoured electrical cables are widely used in various applications. Their robust construction makes them ideal for both indoor and outdoor settings. These cables are perfect for construction sites, underground installations, and agricultural uses. They resist mechanical damage and protect against environmental factors.

In commercial settings, armoured cables are essential for connecting heavy machinery. They provide durability where regular cables may fail. Facilities like factories and warehouses benefit from this protection. Electrical systems in challenging conditions rely on armoured cables for safety and reliability.

Tips: Always check the cable’s ratings when selecting for specific applications. Consider the installation environment carefully. Ensure that the cable thickness meets your requirements. Sometimes, cost might lead to the wrong choice. It's crucial to weigh the importance of safety against price. A cheaper option could turn into a costly failure.

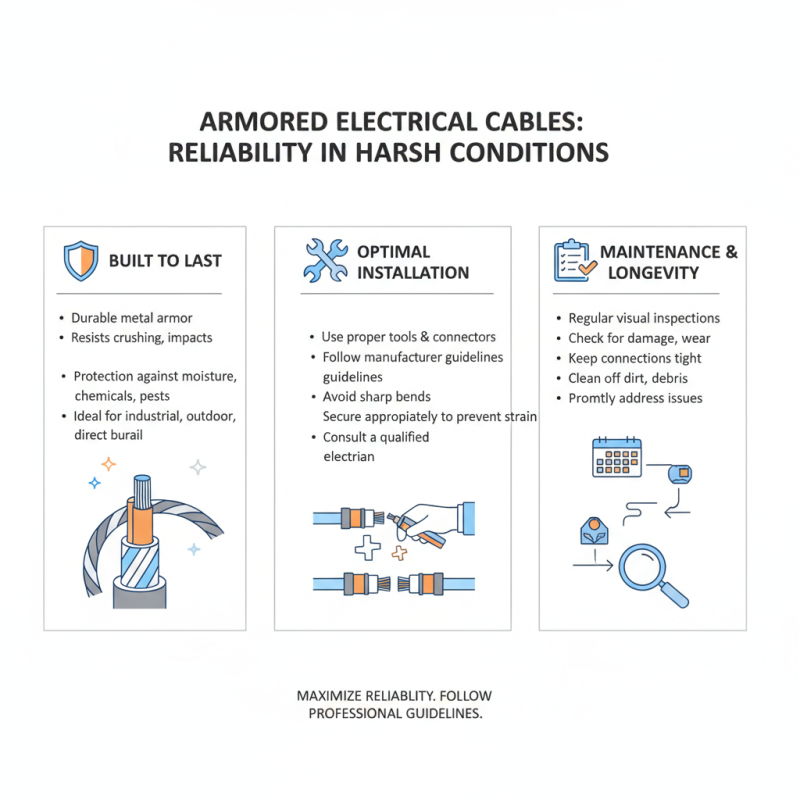

Installation and Maintenance Considerations for Armoured Cables

Armoured electrical cables are designed to withstand harsh conditions, making them ideal for various environments. However, proper installation and maintenance are crucial for maximizing their benefits. Professionals recommend following specific guidelines to ensure reliability.

When installing armoured cables, it is vital to choose appropriate locations. Avoid areas prone to mechanical damage. Buried cables must be protected sufficiently. According to industry reports, nearly 30% of cable failures relate to poor installation practices. Use cable glands and connectors rated for armoured systems to ensure a secure fit. This reduces the risk of water ingress.

Maintenance should not be overlooked. Regular inspections help identify wear and tear. Look for signs of corrosion, especially at joints. A proactive approach can prevent larger issues, which could lead to costly downtime. Be mindful that not all armoured cables are the same. Understanding specific needs is essential for optimal performance.

**Tips:** Always refer to manufacturer guidelines. Use tools that are appropriate for armoured cables. A little care can go a long way.

Related Posts

-

How to Choose the Right Armoured Electrical Cable for Your Specific Needs

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

-

10 Best Micro Coaxial Cables for Unmatched Performance in 2023

-

Understanding the Benefits of Using Flexible Cable Conduit in Your Projects

-

Exploring Cooker Cable Innovations at the 2025 China Import and Export Fair

-

Understanding the Benefits of Metal Clad Cable for Modern Electrical Installations

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•