A partner you can trust

What is Armoured Electrical Cable and How is it Used?

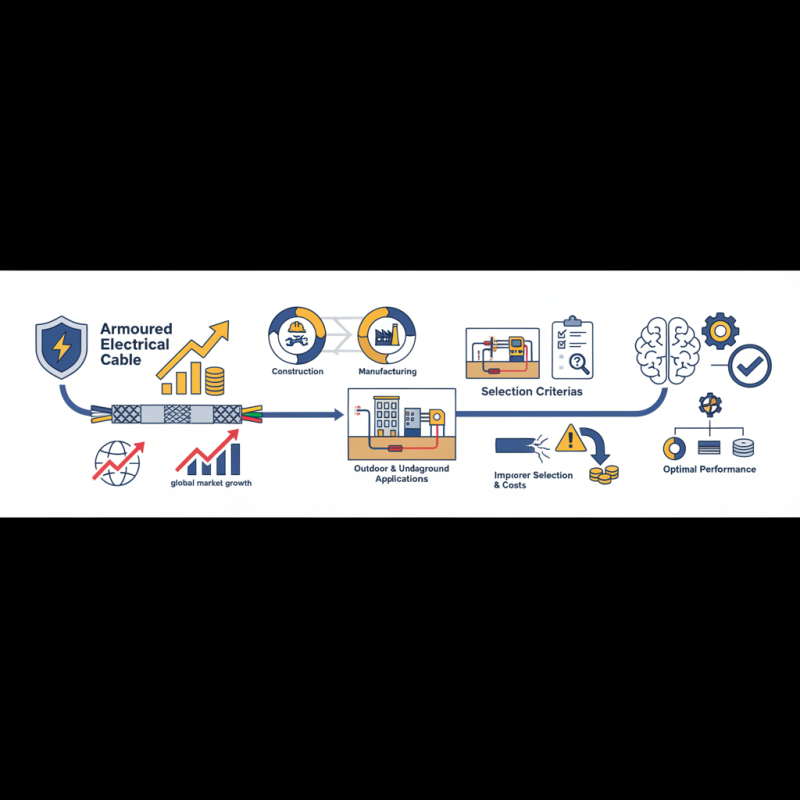

Armoured electrical cable is a crucial component in modern electrical installations. It provides enhanced protection against mechanical damage, moisture, and various environmental factors. According to a report by Grand View Research, the global market for armoured cables is expected to reach USD 16 billion by 2025. This highlights the increasing demand for robust electrical solutions across industries.

In sectors such as construction and manufacturing, armoured electrical cable ensures safety and reliability. It is designed to withstand harsh conditions, making it suitable for outdoor and underground applications. The demand for this type of cable is driven by growing infrastructure projects. However, not all armoured cables are the same. Users often overlook the selection criteria, which can lead to inefficiencies.

The construction industry continues to face challenges with electrical safety. Reports indicate that improper cable selection is a common issue. This can result in significant costs and risks. Understanding the various types of armoured electrical cable is essential for preventing these pitfalls. Awareness of their features and appropriate applications is vital for optimal performance.

What is Armoured Electrical Cable?

Armoured electrical cable is designed for enhanced protection and durability. It consists of multiple layers, often including a tough outer sheath made of steel or aluminum. This construction allows it to withstand mechanical damages, making it ideal for harsh environments. Users often employ this type of cable in industrial settings, outdoors, or underground, where exposure to potential hazards is common.

In many installations, the armoured cable provides added safety. It reduces the risks of electrical faults and damage. Consider how this type of cable is essential in powering heavy machinery or in areas prone to activity such as construction sites. However, armoured cables can be heavy and cumbersome to install. This complexity requires skilled professionals. Mistakes in installation can lead to costly repairs or dangerous situations.

The cost of armoured electrical cable is often higher than standard cables. This may deter some users. However, investing in quality cables can minimize future expenses related to maintenance and replacements. Yet, users sometimes overlook the importance of proper selection. This oversight can affect performance and safety. Recognizing these details is crucial for effective usage.

Types of Armoured Electrical Cables Available

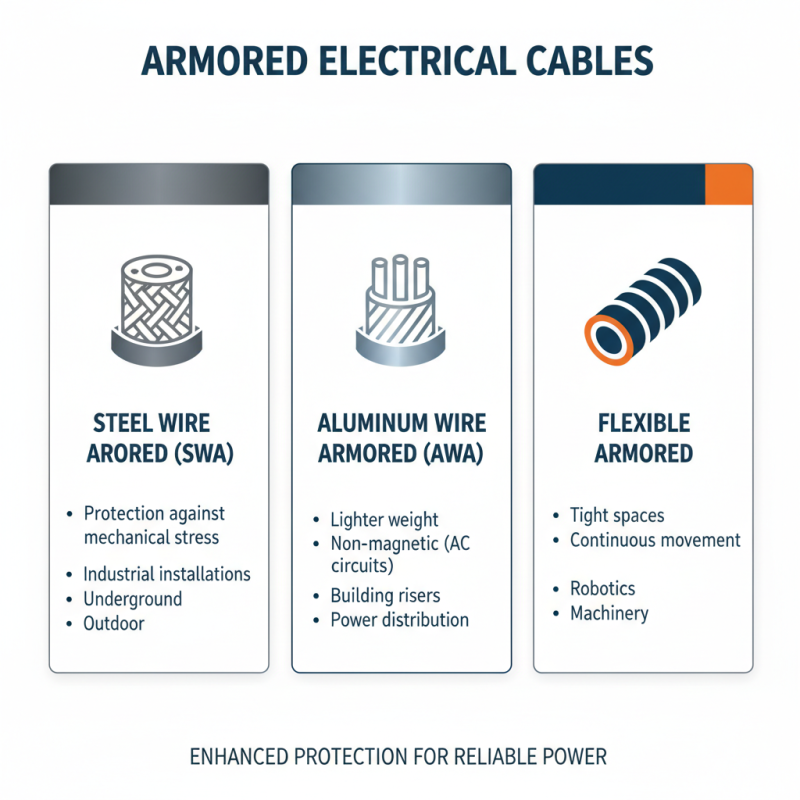

Armoured electrical cables are essential for various applications. They provide increased protection for electrical conductors. The most common types include steel wire armoured (SWA) cables, aluminium wire armoured (AWA) cables, and Flexible armoured cables. Each type serves specific needs in different environments.

SWA cables are highly robust. They are often used outdoors. The steel layer protects against physical damage. AWA cables, on the other hand, are lighter and used in lighter-duty applications. Flexible armoured cables are suitable for areas with constant movement. This design allows for flexibility while ensuring safety.

Tips: When choosing a cable, consider the environment. Look for factors like moisture and temperature. Always check for installation guidelines to avoid mistakes. Moreover, it's important to note that not all armoured cables are suitable for all situations. Think about the installation location and intended use. It's crucial to prevent potential hazards.

Applications of Armoured Electrical Cables in Various Industries

Armoured electrical cables are essential in various industries. They are designed to withstand harsh environments. In construction, these cables protect against pressure and impact. They are often buried underground or installed in risky areas. A report by MarketsandMarkets suggests that the global market for armoured cables will reach $28 billion by 2027, reflecting their growing importance.

In mining and oil sectors, the need for durable cables is even more pronounced. Armoured cables resist chemical corrosion and extreme temperatures. A study by Mordor Intelligence found that around 45% of armoured cables are used in these sectors alone. Their robustness is crucial for safety and efficiency. However, some may overlook installation best practices, leading to potential hazards.

Transportation systems also rely on armoured cables. They ensure reliable communication and power supply in railways and airports. Yet, maintenance is often neglected. According to industry surveys, nearly 25% of infrastructure failures stem from cable issues. This reality calls for better awareness and regular inspections. Proper attention can significantly enhance safety and performance.

Advantages of Using Armoured Electrical Cables

Armoured electrical cables serve an essential role in various installation environments, especially in industrial settings. Their construction includes an extra layer of protection, typically made from steel or aluminum, safeguarding the inner conductors from external damage. This added durability makes them ideal for scenarios where cables may be exposed to mechanical stresses or harsh conditions.

The advantages of using armoured cables are significant. According to industry studies, these cables can reduce maintenance costs by up to 30% due to their resilience. They also provide a higher level of safety, reducing the risk of electrical failure. The armored layer helps to prevent accidental damage from heavy machinery or adverse weather conditions, which is crucial in sectors such as construction and manufacturing.

In addition to physical protection, armoured cables can also enhance performance. They are designed to handle higher currents and voltages effectively. A report from a leading electrical engineering group indicates that correctly installed armoured cables show a lower rate of energy loss. However, installation complexity can be a drawback. Proper training is essential, as incorrect handling can negate the advantages of using these robust cables. Regular reviews on installation practices are valuable to ensure optimal performance and safety.

What is Armoured Electrical Cable and How is it Used? - Advantages of Using Armoured Electrical Cables

| Attribute | Description |

|---|---|

| Type | Steel Wire Armoured (SWA) Cable |

| Construction | A combination of conductive cores, insulation, and an outer protective layer made of steel |

| Usage Areas | Industrial facilities, underground installations, outdoor applications |

| Advantages | Mechanical protection, resistance to moisture, fire resistance, ideal for high voltage applications |

| Installation Method | Directly buried, mounted on walls, or within trunking systems |

| Maintenance | Low maintenance but regular inspections are recommended to ensure integrity |

Installation and Maintenance Considerations for Armoured Cables

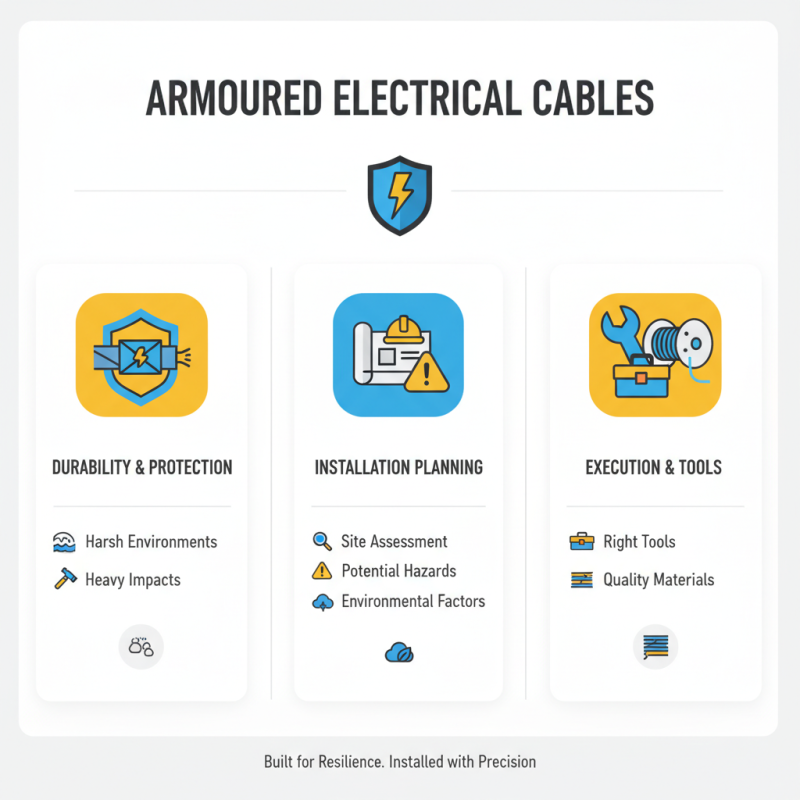

Armoured electrical cables are designed for durability and protection. They can withstand harsh environments and heavy impacts. However, installation requires careful planning and execution. It's essential to assess the site where the cables will be laid. Consider potential hazards and environmental factors. Make sure the right tools and materials are available.

Proper installation also demands attention to detail. The cables should be laid in trenches, avoiding sharp bends. Use protective sleeves where needed. Often, installers overlook proper burial depth. It's vital to follow guidelines to prevent damage from external forces. Regular inspections during and after installation can reveal potential issues. Maintenance is another critical area.

Routine checks are necessary to identify wear and tear. While armoured cables are robust, they are not invincible. Look for signs of corrosion or mechanical damage. Document any findings. Having a response plan for repairs ensures quick action. The life expectancy of cables can be significantly extended with proper care. Nonetheless, it’s easy to neglect regular maintenance in busy operations. Constant vigilance can save time and resources in the long run.

Related Posts

-

How to Choose the Right Armoured Electrical Cable for Your Specific Needs

-

8 Essential Tips for Choosing the Best Outdoor Electrical Cable for Your Next Project

-

How to Choose the Right Electric Cable for Your Global Procurement Needs

-

What is Armoured Electrical Cable and Its Benefits?

-

2026 Best Lead Sheathed Cable Options for Your Projects?

-

Understanding the Benefits of Metal Clad Cable for Modern Electrical Installations

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•