A partner you can trust

Top 10 Benefits of Using Tray Cable Wire for Reliable Electrical Installations in 2023

In the ever-evolving landscape of electrical installations, professionals continue to seek materials that enhance reliability and efficiency. One such material that stands out in 2023 is tray cable wire, which plays a pivotal role in optimizing electrical systems across various industries. According to the National Electrical Manufacturers Association (NEMA), the demand for tray cable wire has surged by 15% over the past year, highlighting its growing significance in modern electrical applications.

Expert in electrical wiring solutions, Dr. Emily Bennett, states, "The use of tray cable wire not only improves the safety and performance of electrical installations but also offers remarkable flexibility that meets today's industrial needs." This statement underscores how tray cable wire helps practitioners achieve compliance with stringent safety standards while ensuring a robust infrastructure.

Expert in electrical wiring solutions, Dr. Emily Bennett, states, "The use of tray cable wire not only improves the safety and performance of electrical installations but also offers remarkable flexibility that meets today's industrial needs." This statement underscores how tray cable wire helps practitioners achieve compliance with stringent safety standards while ensuring a robust infrastructure.

With the continuous advancements in technology and rigorous testing standards, the benefits of tray cable wire have become clearer, making it an indispensable choice for professionals aiming for reliability and effectiveness in their electrical projects. As we delve deeper into the top ten benefits of tray cable wire, it becomes apparent why it will remain a preferred option well into 2025 and beyond.

Top 5 Reasons Why Tray Cable Wire Enhances Electrical Safety and Performance

Using tray cable wire in electrical installations offers numerous advantages, especially when it comes to enhancing safety and performance. One key benefit is its robust design, which provides increased resistance to environmental factors such as moisture and chemicals. This strength contributes to a more reliable wiring system, reducing the likelihood of failures that could lead to accidents or costly repairs.

Another significant reason to opt for tray cable wire is its versatility in application. Tray cables can accommodate various types of conductors and insulation, making them ideal for diverse electrical systems. This flexibility not only simplifies installation but also allows for future upgrades without extensive rewiring, which helps maintain system safety and efficiency over time.

**Tip:** When installing tray cable wire, ensure that the cable is properly secured to prevent any movement that could lead to wear or damage. Additionally, always check local codes and regulations for compliance to enhance overall safety and performance.

**Tip:** Make use of appropriate connectors and termination methods specific to tray cable wire to ensure optimal performance and eliminate potential hazards. Regular inspections can also help identify any issues early, preventing major problems down the line.

Key Features of Tray Cable Wire That Make It Ideal for 2023 Installations

Tray cable wire is increasingly recognized for its unique features that enhance reliability in electrical installations, particularly in 2023. One of the standout characteristics of tray cable wire is its versatility, allowing it to be used in a wide range of environments, from commercial buildings to industrial settings. This adaptability is crucial as it enables installations to meet various regulatory standards while accommodating different types of equipment and systems.

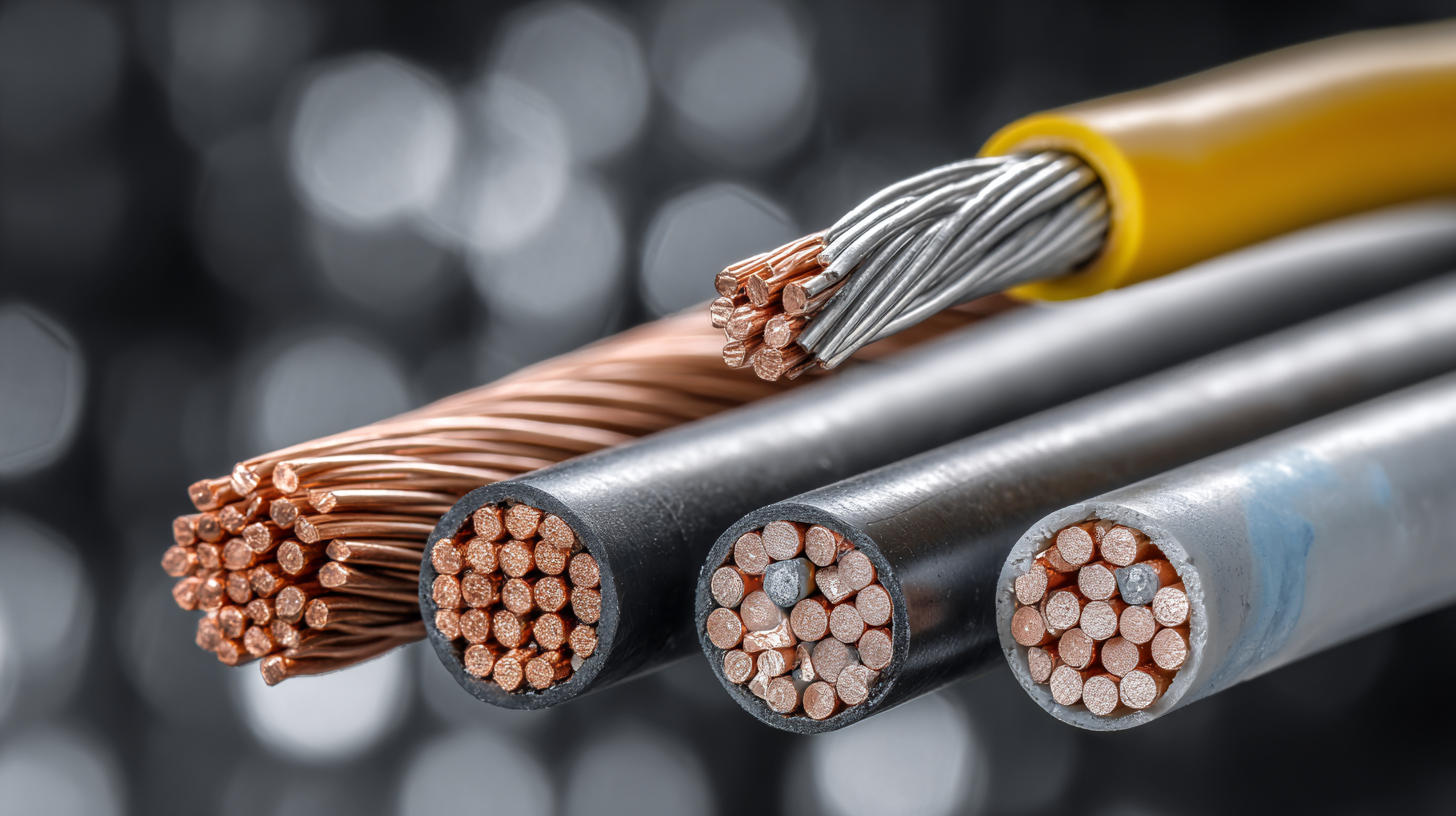

Another key feature is the robust construction of tray cable wire, which typically includes a combination of PVC or thermoplastic elastomerous outer layers and multiple conductors. This design provides excellent protection against physical damage, moisture, and chemicals, ensuring longevity in demanding conditions. Additionally, the use of conductors that allow for higher permissible ampacities means that fewer cables are needed, further simplifying installation and reducing costs. Overall, the inherent benefits of tray cable wire, driven by its key features, position it as a top choice for reliable electrical installations in the current year.

Comparative Advantages: Tray Cable Wire vs. Traditional Wiring Methods

When comparing tray cable wire to traditional wiring methods, several distinctive advantages emerge that position tray cable as a superior choice for installations. Primarily, tray cable wire is designed for flexibility and adaptability, allowing for easier routing in complex environments. Unlike conventional methods, which often require strict adherence to casing and conduits, tray cables can be installed in a variety of configurations and are less susceptible to damage when routed through spaces with varying temperatures and structural changes.

Moreover, tray cable wire enhances safety and efficiency. With its multi-conductor design, it minimizes the number of individual wires needed, reducing clutter and potential hazards associated with tangled wires. This not only streamlines the installation process but also facilitates quicker maintenance and upgrades. Additionally, tray cable wire is resistant to environmental factors like moisture and UV exposure, significantly extending its lifespan compared to traditional methods that may require regular replacements or additional protective measures. As a result, opting for tray cable wire emerges as a forward-thinking decision in ensuring the reliability of electrical systems.

Top 10 Benefits of Using Tray Cable Wire for Reliable Electrical Installations in 2023

| Benefit | Tray Cable Wire | Traditional Wiring Methods |

|---|---|---|

| Flexibility | High flexibility, suitable for various installations | Less flexible, often rigid installations |

| Installation Speed | Faster installation due to pre-assembled nature | Generally slower, requires more time to wire |

| Cost-Effectiveness | Lower installation labor costs | Higher labor costs due to complexity |

| Durability | Highly durable under various environmental conditions | May require additional protection in harsh environments |

| Versatility | Suitable for a wide range of applications | More limited applications based on type |

| Safety | Enhanced safety features | Potential electrical hazards if improperly installed |

| Space Efficiency | Compact design saves installation space | Takes up more space due to bulk |

| Temperature Resistance | Handles temperature extremes well | May not perform well in extreme temperatures |

| Code Compliance | Easily meets industry standards | May require additional modifications for compliance |

| Aesthetic Appeal | Neat appearance with organized layout | Often looks cluttered if not managed |

Cost-Effectiveness of Tray Cable Wire for Long-Term Electrical Solutions

Tray cable wire is increasingly recognized for its cost-effectiveness in long-term electrical installations. As the demand for reliable and efficient energy solutions grows, tray cables offer an economical option for businesses and homeowners alike. These cables are designed to withstand harsh environments while maintaining durability, which reduces the need for frequent replacements and repairs.

This longevity translates to significant savings in both labor and materials over time, making tray cable wire an intelligent choice for those seeking to minimize operational costs.

Moreover, the versatility of tray cable wire contributes to its cost-effectiveness. It can be used in various applications, from commercial to industrial settings, allowing for simplified inventory management and reduced overhead costs. As the global cable cleats market continues to expand, with projections indicating substantial growth, investing in tray cable wire becomes increasingly attractive for sustainable electrical solutions. By choosing this type of wiring, users not only ensure reliable performance but also align their projects with modern economic and environmental priorities.

Understanding the Versatility of Tray Cable Wire in Various Applications

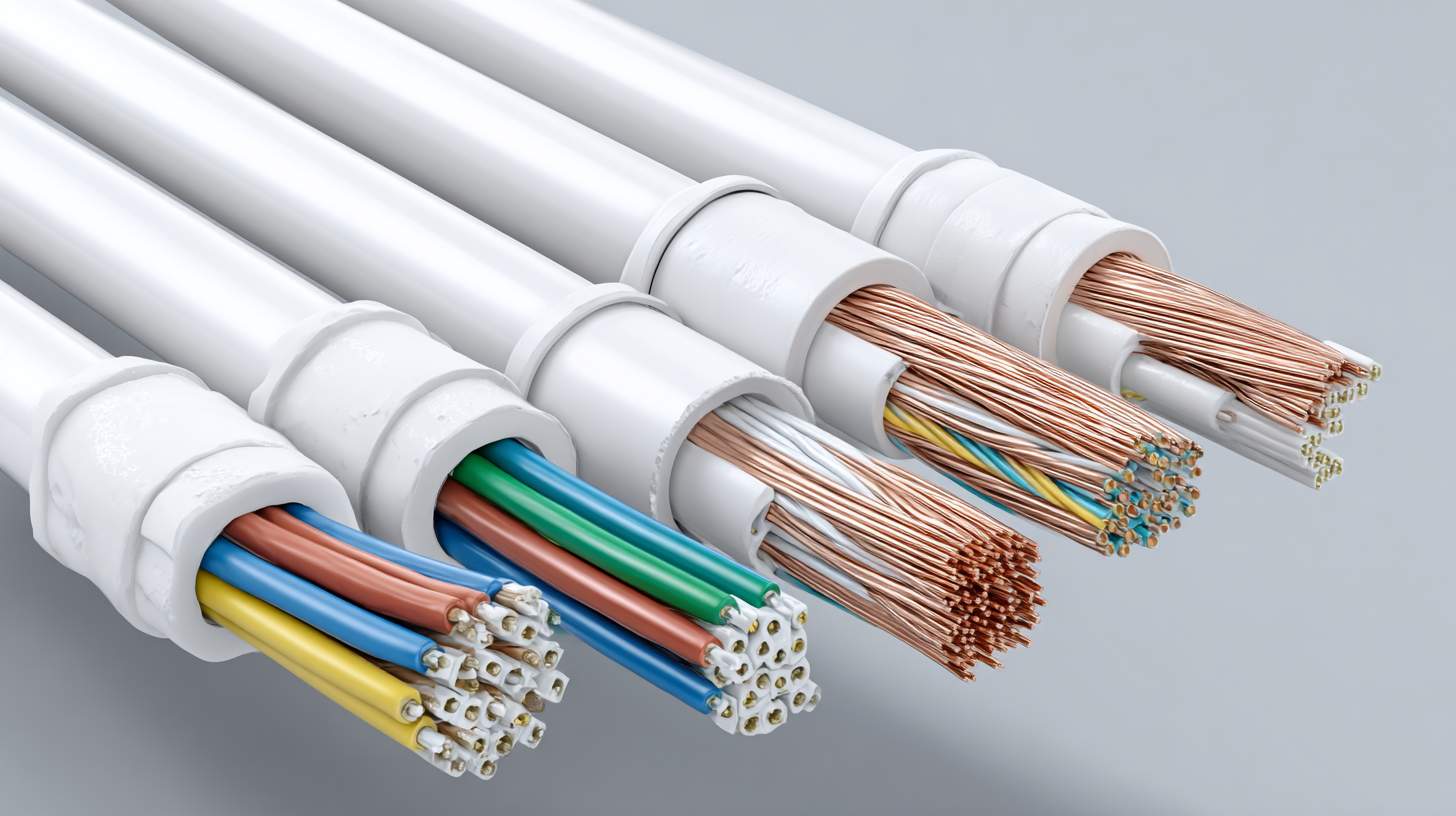

Tray cable wire is an incredibly versatile solution for a wide range of electrical installations. Its design allows for efficient routing and management of various types of cables, including copper data cables, fiber optics, and power cables. This adaptability makes it a preferred choice in environments such as data centers, connected buildings, and industrial settings. The ability to accommodate different types of wiring within one cable assembly streamlines installations and enhances overall operational efficiency.

When using tray cable wire, consider the specific requirements of your environment. For instance, ensure that the cable type matches the data transmission or power needs, as this can significantly impact performance. Additionally, it’s crucial to assess the installation space for any potential constraints that might affect cable routing.

Tips: Always follow local codes and regulations for conduit and cable management to ensure safety and compliance. Planning your layout ahead of installation can also save time and reduce the risk of future issues, allowing for easier upgrades or maintenance in the future.

Top 10 Benefits of Using Tray Cable Wire for Reliable Electrical Installations in 2023

Related Posts

-

The Essential Guide to Choosing the Right Trailer Cable for Your Needs

-

Comprehensive Guide to Selecting the Best Flexible Cable Conduit for Your Project

-

Essential Guide to Choosing the Right Cable Conduit for Your Electrical Projects

-

How to Choose the Right Electric Cable for Your Global Procurement Needs

-

Maximize Your Boat's Performance: Choosing the Right Marine Battery Cable for Optimal Efficiency

-

Exploring the Benefits of Shielded Power Cable for Enhanced Electrical Performance

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•