A partner you can trust

Best Tray Cable Wire Options for Your Electrical Needs?

When considering the best options for tray cable wire, one name stands out: John Smith, a renowned expert in electrical wiring. He emphasizes, "Choosing the right tray cable wire can make or break your project." This highlights the necessity of selecting proper materials for successful electrical installations.

Tray cable wire is essential in various settings, from industrial plants to commercial buildings. It provides reliable power distribution while remaining organized in cable trays. However, navigating the choices available can be overwhelming. The key is understanding the specific needs of your project and the environment in which the cables will be used.

Not all tray cable wire options are equal. Some may offer better insulation, while others might have enhanced flexibility. Reflect on your requirements before making decisions. It’s important to prioritize performance and safety over cost. While a lower price might attract you, the long-term implications of durable materials outweigh initial savings.

Types of Tray Cable Wire and Their Applications

Tray cables are essential for various electrical applications. These cables come in different types, each designed for specific uses. Understanding these types can help you choose the right one for your needs.

One popular type is the Type TC cable. It is suitable for both power and signal transmission. You might use it in industrial settings, especially for connecting motors and control panels. Another option is the Type TC-ER cable, which is suitable for exposed run. This makes it ideal for outdoor applications. The outer jacket protects it from environmental factors.

While selecting tray cable wire, consider the environment. Will it be indoors or outdoors? Each environment has its challenges. You could face moisture, heat, or physical damage. Ignoring these factors may lead to failures. Always check the specifications carefully. A wrong choice can lead to costly repairs. Reflect on your decision-making process for better outcomes.

Key Factors to Consider When Choosing Tray Cable Wire

Choosing the right tray cable wire is crucial for electrical installations. Several key factors influence this decision. First, consider the wire's gauge. A lower gauge means thicker wire. This allows for higher current flow. According to the National Electrical Code (NEC), using the correct gauge can help prevent overheating and ensure safety.

Next, insulation type is paramount. Different installations require specific insulation to handle environmental factors. For instance, PVC insulation is suitable for many indoor applications. However, areas exposed to moisture need specialized insulation. The Wire and Cable Manufacturer’s Association reports that improper insulation can lead to costly failures.

Another crucial aspect is the cable's flexibility. In tight spaces, flexible cables can ease installation. Studies indicate that rigid cables often cause stress on connections. This may lead to premature wear. Additionally, consider the length of the run. Longer distances can lead to voltage drop, affecting efficiency. Analyzing these factors ensures you select the best tray cable for your needs.

Best Tray Cable Wire Options for Your Electrical Needs

The following chart illustrates the temperature ratings of various types of tray cable wires, helping you to choose the best option for your electrical needs. Consider these ratings when selecting a cable type for your specific application.

Comparing Copper and Aluminum Tray Cable Wires

When it comes to tray cable wires, the choice between copper and aluminum is crucial. Copper wires, known for their conductivity, deliver lower resistance. Studies indicate that copper has a conductivity rate of 97% IACS (International Annealed Copper Standard). This superior conductivity can lead to a smaller gauge size, making it easier to fit into tighter spaces.

On the other hand, aluminum is lighter and often more cost-effective. It has a conductivity rate of about 61% IACS. However, this higher resistance means that larger gauge sizes are typically required for the same current capacity. The need for larger cables can make installation more challenging, especially in cramped environments.

Some industry reports show that while aluminum wires can save money upfront, the long-term performance varies. Issues like oxidation can increase resistance over time. In scenarios with extreme temperature fluctuations, aluminum may also expand and contract more than copper. This behavior can compromise connections, leading to potential safety concerns. Understanding these nuances is vital when selecting the right tray cable for your electrical needs.

Understanding Tray Cable Ratings and Standards

Tray cables are essential for various electrical applications. Understanding their ratings and standards is crucial. These cables often carry power and control signals in industrial settings. They’re designed to be installed in cable trays, which protect them while allowing for effective heat dissipation.

One key standard is the National Electrical Code (NEC). The NEC defines the types and ratings of tray cables. For instance, Type TC cables are suitable for use in trays and can handle different voltage levels. They are rated for direct sunlight exposure and are often moisture-resistant. A report by the National Fire Protection Association highlights that improper installation of these cables could lead to significant fire hazards.

Moreover, the Underwriters Laboratories (UL) certification provides an additional layer of safety. A UL listing means the cable has passed rigorous tests. However, many installers overlook the importance of regular inspections. Regular checks can spot potential issues. Ignoring this can lead to severe problems down the line. Quality should always be prioritized when selecting tray cables, but understanding these ratings is equally crucial for safe operation.

Maintenance Tips for Tray Cable Wire Installation

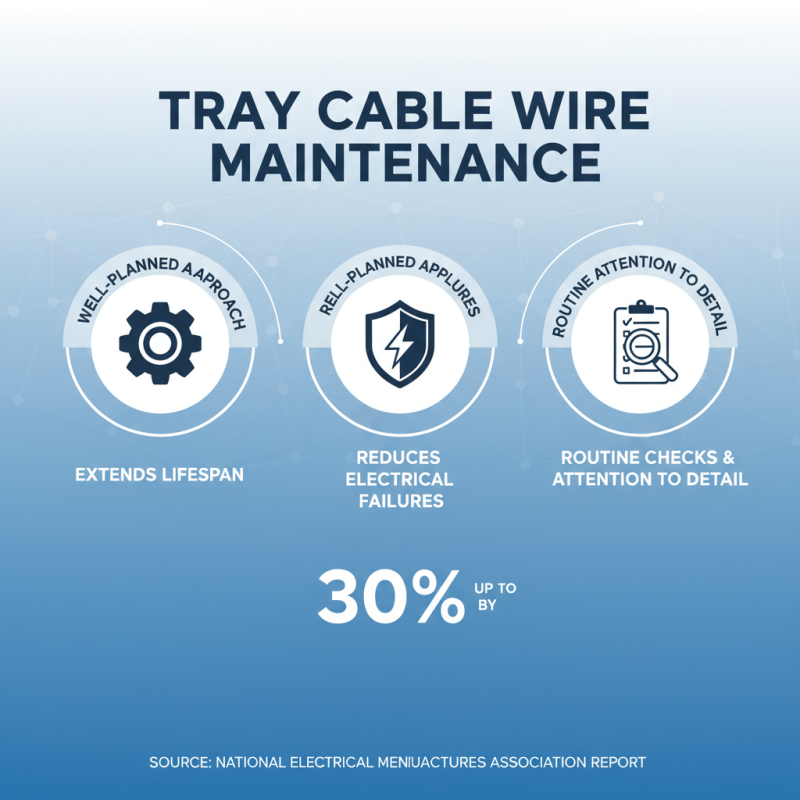

When it comes to tray cable wire installation, maintenance is crucial. A well-planned approach can significantly extend the lifespan of your wiring system. For instance, according to a report by the National Electrical Manufacturers Association, proper maintenance can reduce electrical failures by up to 30%. This statistic highlights the importance of routine checks and attention to detail.

Regular inspections should focus on physical damage, fraying, or corrosion. Tray cables are designed to withstand various environmental factors. However, they are not indestructible. It’s essential to ensure that cables are not exposed to unnecessary stress or movement. Identifying these issues early can prevent unexpected downtime, which can be costly.

Additionally, must consider the environment where tray cables are installed. Excessive moisture or heat can affect performance. A study found that nearly 25% of electrical failures occurred due to improper environmental conditions. Always assess the installation area carefully. Use protective measures, like conduits or trays, to shield cables from harsh elements. This can be a simple and effective preventative step.

Related Posts

-

Essential Tips for Choosing Tray Cable Wire for Your Project?

-

Top 10 Benefits of Using Tray Cable Wire for Reliable Electrical Installations in 2023

-

The Best 10 Tray Cable Wire Types for Your Electrical Projects

-

7 Best Practices for Using Wire Mesh Cable Tray in Modern Data Centers

-

Essential Tips for Choosing the Right Cooker Cable for Your Kitchen Needs

-

Exploring EV Ultra Cable Innovations at the 2025 China Import and Export Fair with Market Growth Projections

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•