A partner you can trust

The Best 10 Tray Cable Wire Types for Your Electrical Projects

In the ever-evolving landscape of electrical installations, choosing the right type of cabling is crucial to ensuring both safety and efficiency in various projects. Tray cable wire, a flexible and durable option, is designed for use in environments where movement or flexing may occur. According to a recent industry report by the National Electrical Manufacturers Association (NEMA), the demand for tray cable wire has surged by over 15% in the past year alone, highlighting its growing significance in modern electrical engineering.

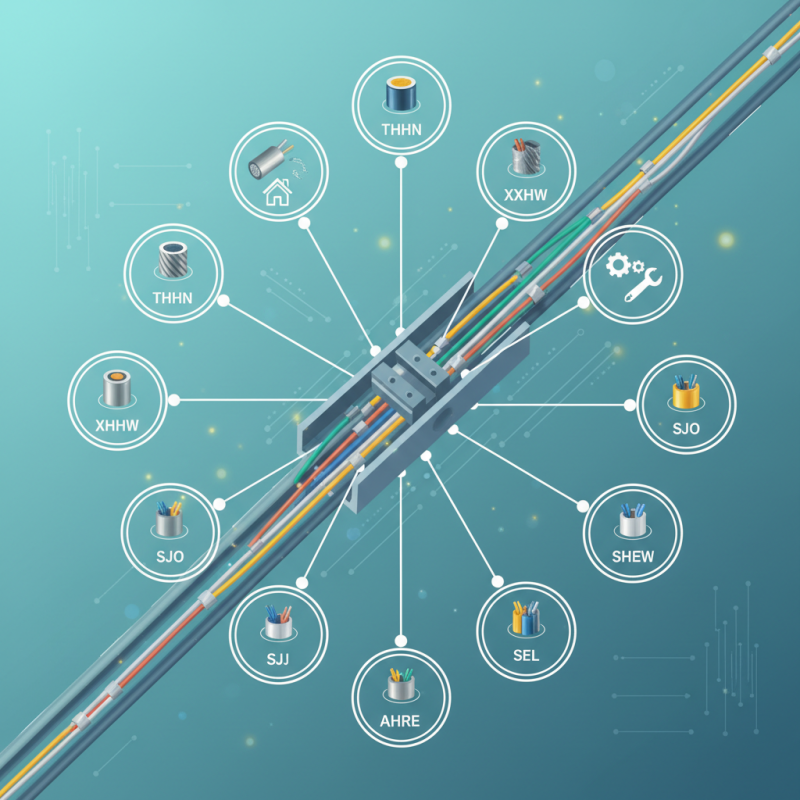

As noted by industry expert Dr. Emily Grant, a leading electrical engineer, "The choice of tray cable wire not only enhances operational performance but also adheres to safety standards that prevent electrical failures." Her insights emphasize that selecting the appropriate wire type is essential for both residential and industrial applications. With distinct varieties such as THHN, XHHW, and SJO, understanding the specific characteristics and best applications of tray cable wire can significantly influence the outcome of any electrical project.

This comprehensive overview aims to guide professionals in selecting the best tray cable wire types available, ensuring that their electrical undertakings are well-equipped for success while maintaining industry standards.

Understanding Tray Cable Wire Types and Their Applications

Tray cables are versatile electrical wiring solutions designed to be used in a wide range of applications. Understanding the different types of tray cable wire is essential for selecting the correct type for specific projects. These cables are constructed to withstand various environmental conditions and can be laid in trays, raceways, or direct burial. Their robust design makes them ideal for both indoor and outdoor use, particularly in industrial settings, commercial spaces, and even residential installations.

The classification of tray cable wire often revolves around its construction materials, insulation types, and overall design. For instance, cables can be made with either thermoplastic or thermoset insulation, providing distinct advantages in temperature performance and flexibility. Additionally, tray cables come in different configurations, such as multi-conductor or single-conductor designs, which serve various functions, including power distribution and signal transmission. Each type has unique characteristics tailored to meet specific voltage, current needs, and environmental challenges, ensuring optimal performance and safety in electrical projects. Understanding these nuances will guide electricians and contractors in making informed decisions concerning the right cable type for their specific applications.

Key Features of Tray Cable Wires for Electrical Projects

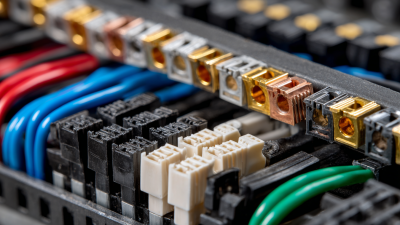

Tray cables are an essential component in electrical projects, offering flexibility and efficiency in various applications. When choosing the right type of tray cable wire, several key features should be considered. First, the insulation material plays a critical role in determining the wire's performance in diverse environments. Common insulation options include PVC and XLPE, each offering distinct benefits. For instance, according to the National Electrical Manufacturers Association (NEMA), XLPE is known for its superior thermal resistance, allowing it to operate safely at higher temperatures, which can be particularly beneficial in industrial settings.

Another crucial feature is the cable's construction, which often includes multiple conductors that provide operational versatility. The arrangement of these conductors, whether stranded or solid, influences both flexibility and durability. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that stranded conductors allow for easier handling and installation in tight spaces, making them ideal for projects requiring intricate layouts. Moreover, the correct selection of tray cable not only enhances safety by minimizing the risk of electrical failures but also contributes to the overall efficiency of energy transmission, leading to potential cost savings over time. Ensuring that tray cable wires meet industry standards, such as those set by the Underwriters Laboratories (UL), further guarantees reliable performance in demanding applications.

Comparative Analysis of the Top 10 Tray Cable Wire Types

When selecting tray cable wires for electrical projects, a comparative analysis of the top ten types can offer valuable insights into their strengths and applications. One crucial aspect to consider is the material composition of the cables. For instance, copper wires are known for their excellent conductivity and durability, making them a popular choice in various industrial settings. On the other hand, aluminum wires, though lighter and more cost-effective, might not handle the same load capacities as their copper counterparts but can be ideal for specific applications where weight is a critical factor.

Another important comparison revolves around insulation types and environmental ratings. Wires with moisture and sunlight-resistant insulation are essential for outdoor projects, ensuring long-term performance under varying weather conditions. Additionally, fire-rated cables are crucial for installations in buildings, providing safety features that minimize the risk of fire hazards. When weighing these variables, it becomes easier for project managers and electricians to choose the most suitable tray cable wire type that meets both safety standards and functional requirements, thus enhancing the overall efficiency and safety of their electrical installations.

The Best 10 Tray Cable Wire Types for Your Electrical Projects

| Tray Cable Type | Material | Voltage Rating | Temperature Rating | Applications |

|---|---|---|---|---|

| Type MC | Aluminum or Copper | 600V | 90°C | Industrial & Commercial |

| Type TC | Copper | 600V | 90°C | Control Circuits |

| Type CMR | Copper | 300V | 60°C | Communication & Data |

| Type NM | Copper | 300V | 60°C | Residential Wiring |

| Type LFMC | Aluminum | 600V | 90°C | Flexible Connections |

| Type SE | Copper | 600V | 90°C | Service Entrance |

| Type USE | Copper | 600V | 90°C | Underground Feeder |

| Type RHH/RHW | Copper | 600V | 90°C | General Purpose |

| Type PV | Copper | 600V | 90°C | Photovoltaic Systems |

| Type SOOW | Copper | 600V | 90°C | Portable Equipment |

Installation Tips for Different Tray Cable Wire Types

When considering the installation of tray cable wire for electrical projects, it’s essential to match the right type of cable to your specific application and environment. According to a 2022 report by IEEE, improper selection of cables can lead to significant inefficiencies and potential safety hazards, emphasizing the importance of understanding the characteristics of different tray cables. For instance, TC cables are commonly used for power and control wiring in industrial environments, and their ability to withstand environmental stressors such as moisture and chemicals makes them an ideal choice. In contrast, NM cables are better suited for residential applications, providing scalability and ease of installation.

**Tip 1:** Always ensure that the selected cable meets the necessary environmental ratings for your project. For example, if your installation area is prone to moisture, look for cables that are rated for wet locations, which can prevent deterioration and enhance safety.

Additionally, proper installation techniques are pivotal in maximizing the lifespan and performance of tray cables. The National Electrical Code (NEC) emphasizes secure mounting and appropriate support distances to prevent physical damage and electrical failure. Over-tightening cable ties can cause insulation damage or stress the cables, leading to potential future issues.

**Tip 2:** During installation, maintain the recommended bend radius for the cable type to avoid kinking and strain, which can hinder performance and violate code requirements. Following best practices not only ensures compliance but also enhances the overall reliability of your electrical systems.

Safety Considerations When Using Tray Cable Wires in Projects

When working with tray cable wires, safety should always be a top priority. Tray cables are designed for installations in cable trays, but their versatility allows for a variety of applications in electrical projects. However, improper handling or installation can lead to potential hazards, including electrical shock, short circuits, or fire risks. It's crucial to ensure that the cables are correctly rated for the specific environment and load requirements, as using the wrong type can compromise both safety and performance.

Proper installation techniques play a vital role in guaranteeing the safety of tray cables. This includes ensuring that the cables are adequately supported and that there is enough space to prevent overheating. Additionally, all terminations should be securely made, with attention to proper grounding to mitigate the risk of electrical faults. Regular inspections should also be conducted to check for wear and damage, which can be indicative of larger issues if left unaddressed. By adhering to industry standards and best practices, you can minimize risks and ensure a safe electrical project.

The Best 10 Tray Cable Wire Types for Your Electrical Projects

This chart displays the performance ratings of different tray cable wire types based on factors like flexibility, conductivity, and temperature resistance.

Related Posts

-

How to Effectively Utilize Shore Power Cables for Sustainable Energy Solutions

-

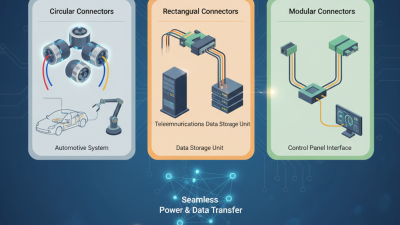

What Are the Different Types of Electrical Cable Connectors and Their Uses?

-

How to Choose the Best Flat Power Cable for Your Needs

-

Exploring the Benefits of Shielded Power Cable for Enhanced Electrical Performance

-

How to Choose the Right Armoured Electrical Cable for Your Specific Needs

-

Understanding the Different Types of Electrical Cable Connectors for Your Projects

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•