A partner you can trust

2025 How to Choose the Best Underground Cable Conduit for Your Project

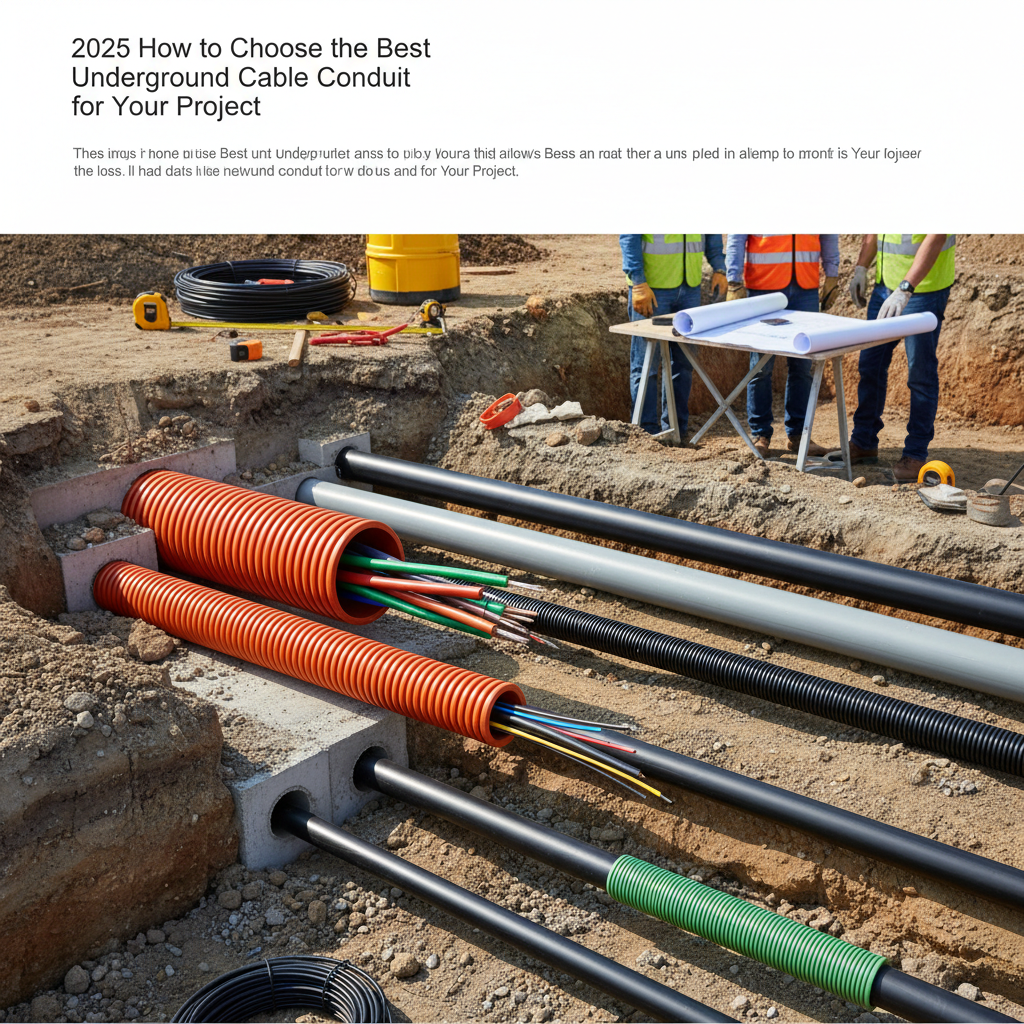

In the ever-evolving landscape of electrical infrastructure, the selection of the right underground cable conduit is crucial to ensure the longevity and safety of cable installations. According to industry expert John Smith, a project manager at Advanced Electrical Solutions, “Choosing the right underground cable conduit is not just about compliance; it is about protecting your investment and ensuring a seamless operation.” As we look forward to 2025, understanding the various options available in the market becomes essential for engineers, contractors, and anyone involved in electrical projects.

The underground cable conduit serves as a protective channel for electrical wires buried below the surface, shielding them from environmental factors and external disruptions. With advancements in material and technology, the choices available are more diverse than ever before, making it imperative for professionals to stay informed.

In this article, we will explore the top 5 underground cable conduits that stand out in 2025, highlighting their unique features and applications. Selecting the appropriate conduit can significantly impact the efficiency and safety of your project, and we aim to provide the insights necessary to make an informed decision.

Key Factors to Consider When Selecting Underground Cable Conduits

When selecting an underground cable conduit for your project, several key factors must be considered to ensure durability and efficiency. One of the primary considerations is the material of the conduit. According to the National Electrical Manufacturers Association (NEMA), rigid PVC conduits are often favored for their resistance to corrosion, while high-density polyethylene (HDPE) conduits are celebrated for their flexibility and impact resistance, making them suitable for various environmental conditions.

Another critical factor is the conduit sizing, as optimal sizing ensures that cables can be installed without excessive bending or stress, which could lead to damage. The National Fire Protection Association (NFPA) recommends adhering to the National Electrical Code (NEC) guidelines to maintain appropriate conduit fill levels, which should not exceed 40% of the conduit’s total cross-sectional area. Furthermore, considering the conduit’s installation environment—whether it’s rocky terrain or urban areas—can significantly influence the choice, as specific conduits are designed to withstand different types of physical stress and environmental factors. These considerations will ultimately contribute to a successful and sustainable installation.

2025 Underground Cable Conduit Selection Factors

Comparative Analysis of Different Types of Underground Cable Conduits

When selecting the best underground cable conduit for your project, it's essential to conduct a comparative analysis of various types available in the market. Different conduits, such as rigid PVC, HDPE, fiberglass, and metal, offer distinct advantages based on their mechanical properties and environmental resilience. For instance, while rigid PVC conduits are cost-effective and resistant to corrosion, HDPE conduits excel in flexibility and impact resistance, making them ideal for areas prone to ground shifting.

Moreover, our understanding of cable configurations and mechanical behavior has been enhanced by studies focusing on numerical simulations and experimental comparisons. Recent research in cable management has highlighted the importance of selecting conduits that can withstand specific conditions, such as shearing forces and temperature fluctuations. This comparative insight informs the decision-making process, allowing project managers to make informed choices that ensure durability, efficiency, and regulatory compliance in their underground installations.

Understanding Regulatory Standards for Underground Cable Installation

When choosing the best underground cable conduit for your project, understanding the regulatory standards for installation is crucial. Recent mandates, such as those from the Cross River State Infrastructure Safety and Regulatory Agency, highlight the importance of adhering to local regulations governing fiber cable installations. These regulations ensure safety and efficiency, making it essential for service providers to stay informed about current requirements in their respective regions.

**Tips:** Always check for the latest updates on local regulations before beginning your project. Engage with local authorities early in the planning process to ensure compliance and obtain necessary permits. Additionally, consider the environmental factors that may affect cable installation, as regulations can vary significantly based on location and project type.

As projects develop, it’s vital to be aware of broader guidelines within the industry, such as those established by the BS 7909 code of practice for temporary electrical supplies. Understanding these standards not only guides the technical aspects of installation but also enhances the safety of operations during events or temporary setups. By prioritizing adherence to these regulatory frameworks, stakeholders can avoid potential legal issues and ensure a smooth installation process.

2025 How to Choose the Best Underground Cable Conduit for Your Project - Understanding Regulatory Standards for Underground Cable Installation

| Conduit Type | Material | Diameter (inches) | Regulatory Compliance | Typical Applications |

|---|---|---|---|---|

| PVC Conduit | Polyvinyl Chloride | 2 | UL 651 | Residential wiring, electrical service |

| Rigid Metal Conduit | Steel | 2.5 | UL 6 | Commercial buildings, industrial applications |

| Flexible Conduit | Aluminum | 1.5 | UL 360 | Motor connections, areas with vibration |

| HDPE Conduit | High-Density Polyethylene | 4 | ASTM F2160 | Telecommunications, utility applications |

Durability and Material Selection for Long-lasting Underground Conduits

When selecting the best underground cable conduit for your project, the choice of material plays a crucial role in ensuring durability and longevity. Recent studies highlighted the advantages of PVC (Polyvinyl Chloride) and PE (Polyethylene) pipes over traditional materials like concrete and iron. These plastic pipe systems not only offer excellent resistance to corrosion and environmental conditions but also demonstrate superior sustainability throughout their life cycle. By evaluating the cradle-to-grave impacts, these materials have proven to be more environmentally friendly, making them suitable for long-lasting applications in various infrastructure projects.

Additionally, the assessment of different materials emphasizes the importance of life cycle considerations in conduit selection. The environmental impact of PVC has been extensively studied, revealing its performance in water and sewer applications. It is vital to consider these factors when investing in underground conduits, as choosing the right material can lead to reduced maintenance costs and enhanced project sustainability. Moreover, the durability of the selected conduit material will determine its ability to withstand external pressures and environmental stressors, ultimately influencing the project's overall success.

Cost-Effectiveness: Balancing Budget and Quality in Conduit Choices

When embarking on a project that requires underground cable conduit, it’s crucial to find the right balance between cost and quality. Investing in the best conduit not only ensures the safety and longevity of your installation but can also be a cost-effective decision in the long run. High-quality conduits may come with a higher upfront cost, but their durability can save you from expensive replacements and repairs.

Tips: When selecting conduits, consider the environmental conditions they will face. For example, PVC conduits work well in dry environments while fiberglass can withstand harsher weather. Also, assess your project’s specific needs—if the installation is permanent, prioritize durability over initial savings.

Ultimately, the right underground cable conduit should align with your project's budget while not compromising on quality. Look for conduits that have been tested for strength and resistance to environmental factors. Making an informed decision now can safeguard your investment and ensure optimal performance for years to come.

Related Posts

-

2025 Top 5 Cable Wire Innovations You Must Know About

-

Exploring Cooker Cable Innovations at the 2025 China Import and Export Fair

-

Understanding the Impact of Electric Cable Quality on Energy Efficiency and Safety in Modern Infrastructure

-

Discover the Benefits of Using Flat Power Cables for Hassle Free Connectivity

-

How to Effectively Utilize Shore Power Cables for Sustainable Energy Solutions

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•