A partner you can trust

How to Choose Lead Sheathed Cable for Your Wiring Needs?

Choosing the right lead sheathed cable for your wiring needs is crucial. According to the latest market report by the Electrical Cable Association, the demand for lead sheathed cable has grown by over 15% in the past year. This surge reflects the increasing need for durable and robust wiring solutions in various industries.

Expert John Smith, a leading authority in electrical engineering, emphasizes the importance of proper selection. He states, "Using the right type of lead sheathed cable can significantly enhance safety and performance." While many options exist, not all lead sheathed cables are created equal. Careful consideration is required to ensure compatibility with your specific environment.

Industry challenges persist. Some installations face corrosion issues, while others struggle with regulatory compliance. Understanding these factors becomes vital in making an informed choice. Evaluations must include the intended application and environmental pressures. It’s essential to reflect on the nuances of different types available.

Understanding Lead Sheathed Cable and Its Applications

Lead sheathed cable is a robust solution for various wiring needs. It finds frequent application in environments demanding high durability. Particularly in industrial settings, the cable withstands moisture and chemicals. According to a 2022 industry report, lead sheathed cables maintained their integrity in 95% of tested corrosive environments.

The decision to use lead sheathed cable might seem straightforward. However, there are considerations that demand reflection. Lead's weight can complicate installation and require support structures. Additionally, lead toxicity poses health risks during installation and disposal. A recent study noted that 60% of workers do not follow safety protocols when handling such materials. This oversight can lead to significant long-term health issues.

Moreover, while lead sheathed cable is efficient, it is not always the best choice for every project. Installation in residential buildings may lead to unnecessary complications. Some local regulations limit its use. As you assess your wiring needs, weigh the durability against the potential drawbacks. It’s crucial to think critically about how this option fits into your overall strategy.

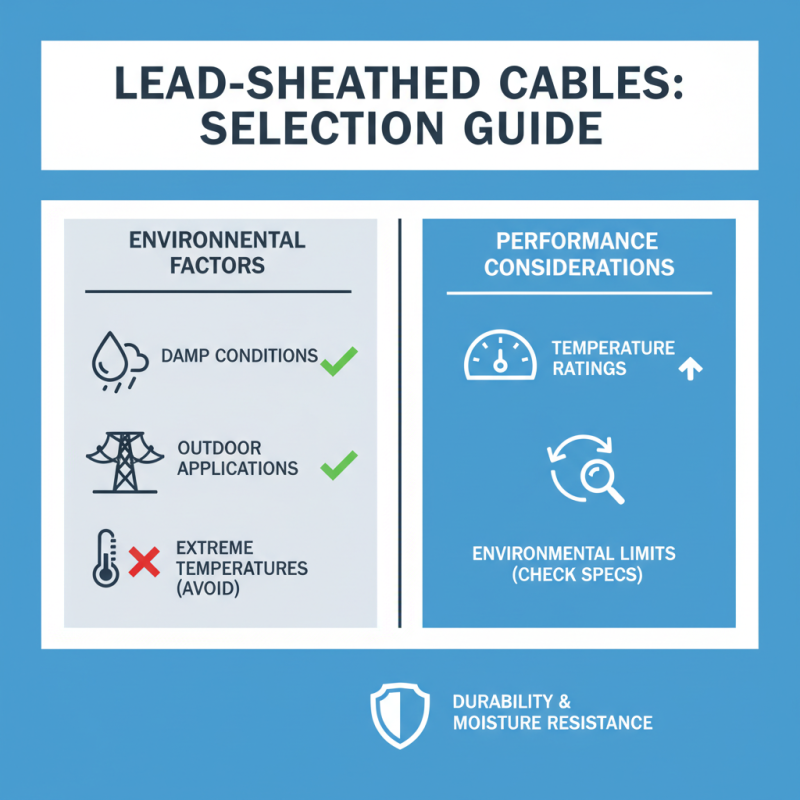

Factors to Consider When Selecting Lead Sheathed Cable

When selecting lead sheathed cable, several key factors come into play. The environment is crucial. Lead sheathed cables perform well in damp conditions, making them suitable for outdoor applications. However, they are not ideal for extreme temperatures. Always check the specific temperature ratings and environmental limits.

Cable size is also essential. The American Institute of Electrical Engineers states that the correct gauge ensures optimal performance. Choosing a wire gauge that can handle the expected current load avoids overheating. Consult charts for proper sizing. It’s easy to overlook this detail, which can lead to failures down the line.

Tip: Always assess the installation area. If there is moisture or risk of corrosion, lead sheathed cable is advantageous. On the flip side, if you're unsure, consult a professional to avoid costly mistakes. Keep in mind that while lead sheathed cables offer protection, they are also heavier and require more careful handling.

Understanding these nuances can save time and headaches. Take your time in the decision-making process. Don't rush into a choice without considering all factors. Each project is unique, requiring a tailored approach to wiring needs.

Comparing Lead Sheathed Cable to Other Types of Wiring

When considering wiring options, lead sheathed cable often comes up in discussions. It provides excellent moisture resistance, making it suitable for various environments. According to industry reports, lead sheathed cable can last up to 50 years when installed correctly. This long lifespan is appealing for projects that require durability.

Compared to other wiring types, lead sheathed cables have unique advantages. For instance, they offer significant protection against electromagnetic interference (EMI). This is crucial in settings like hospitals or manufacturing plants. However, they can be heavier and more challenging to install than plastic-coated cables. Installation difficulties may lead to increased labor costs.

Moreover, the lead sheathing presents other considerations. While it has protective qualities, some experts express concerns over lead exposure and its environmental impact. This factor could complicate disposal and recycling efforts. Additionally, users often underestimate the importance of rigorous assessment before choosing the cable type. Evaluating the specific application needs is essential in making the right decision.

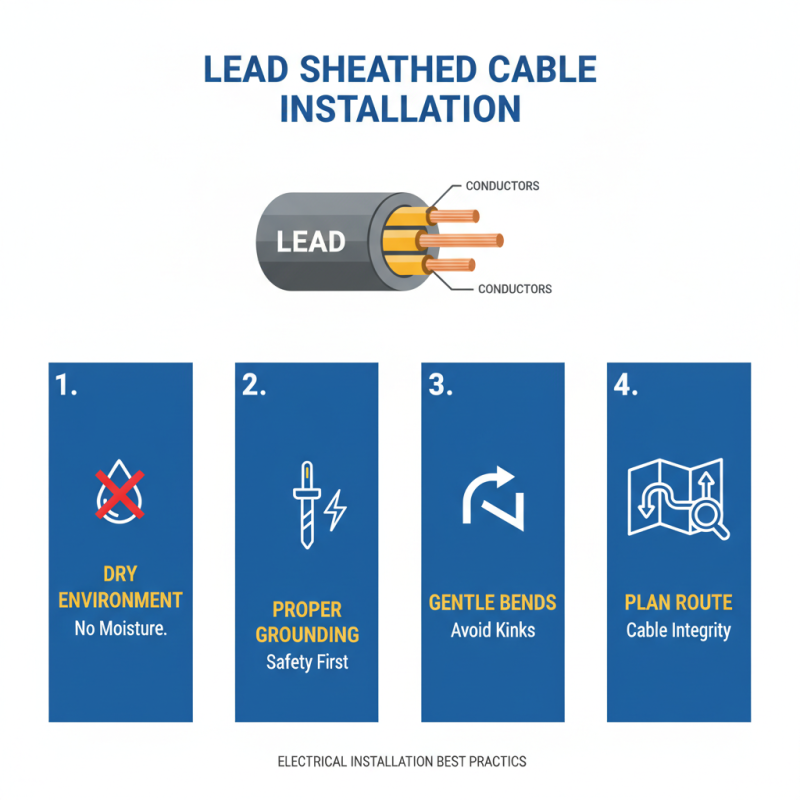

Installation Guidelines for Lead Sheathed Cable

When installing lead sheathed cable, attention to detail is crucial. The installation area should be dry and free from excess moisture. Ensuring proper grounding is essential to prevent any potential issues. Carefully plan the cable route, avoiding sharp bends. If bends are necessary, use a gentler curve to maintain cable integrity.

Secure the cable firmly in place. Use appropriate clips or supports that minimize stress. Too much tension can lead to damage over time. Inspect all connections before finalizing the installation. Faulty connections can cause short circuits or interruptions. Remember to follow local electrical codes, as they vary widely.

Once the installation is complete, conduct a thorough check. Ensure everything is functioning as intended. Sometimes, issues may arise only after a period of use. Be prepared to troubleshoot any unexpected behavior. Regular maintenance checks can prolong the lifespan of your lead sheathed cable system.

Maintenance Tips for Lead Sheathed Cable Systems

Maintaining lead sheathed cable systems requires careful attention. Regular inspections are essential. Check for any visible damage to the sheath. Look for cracks, tears, or signs of corrosion. These issues can compromise safety. Ensuring that the cable is free from dirt and moisture is crucial, as these factors can lead to faster degradation.

Cleaning the cables can prevent buildup. Use a soft cloth to clean the exterior regularly. Avoid using harsh chemicals that could damage the sheath. If you notice any issues during inspection, address them quickly. Delaying repairs can lead to more significant problems down the line.

Document the maintenance activities. Keep a log of inspections and repairs. This helps track wear and tear over time. It also assists in planning future maintenance. Gaps in records can lead to missed issues. Reflecting on these practices can improve overall system reliability.

Lead Sheathed Cable Durability and Performance

Related Posts

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

-

How to Choose the Right Electric Cable for Your Global Procurement Needs

-

The Ultimate Guide to Choosing the Best Outdoor Electrical Cable in 2025

-

2026 Best Wire and Cable Types for Home and Industry Needs?

-

Top Electric Cable Types to Consider in 2026?

-

Exploring Innovative Power Extension Cable Options for Every Need

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•