A partner you can trust

How to Choose the Right Micro Coaxial Cable for Your Application

In today's fast-paced technological landscape, the demand for efficient and reliable micro coaxial cables is on the rise, driven by advancements in telecommunications, aerospace, and medical devices. According to a report by MarketsandMarkets, the global coaxial cable market is projected to reach $37.3 billion by 2025, underscoring the crucial role of micro coaxial cables in high-frequency signal transmissions. These cables are engineered for applications requiring minimized size and weight while maintaining exceptional performance. Selecting the right micro coaxial cable is essential, as it can significantly impact signal integrity, transmission speed, and overall system efficiency. This article will explore the key factors to consider when choosing the appropriate micro coaxial cable for your specific application, ensuring that you make an informed decision that meets the technical requirements and industry standards.

Factors to Consider When Selecting a Micro Coaxial Cable

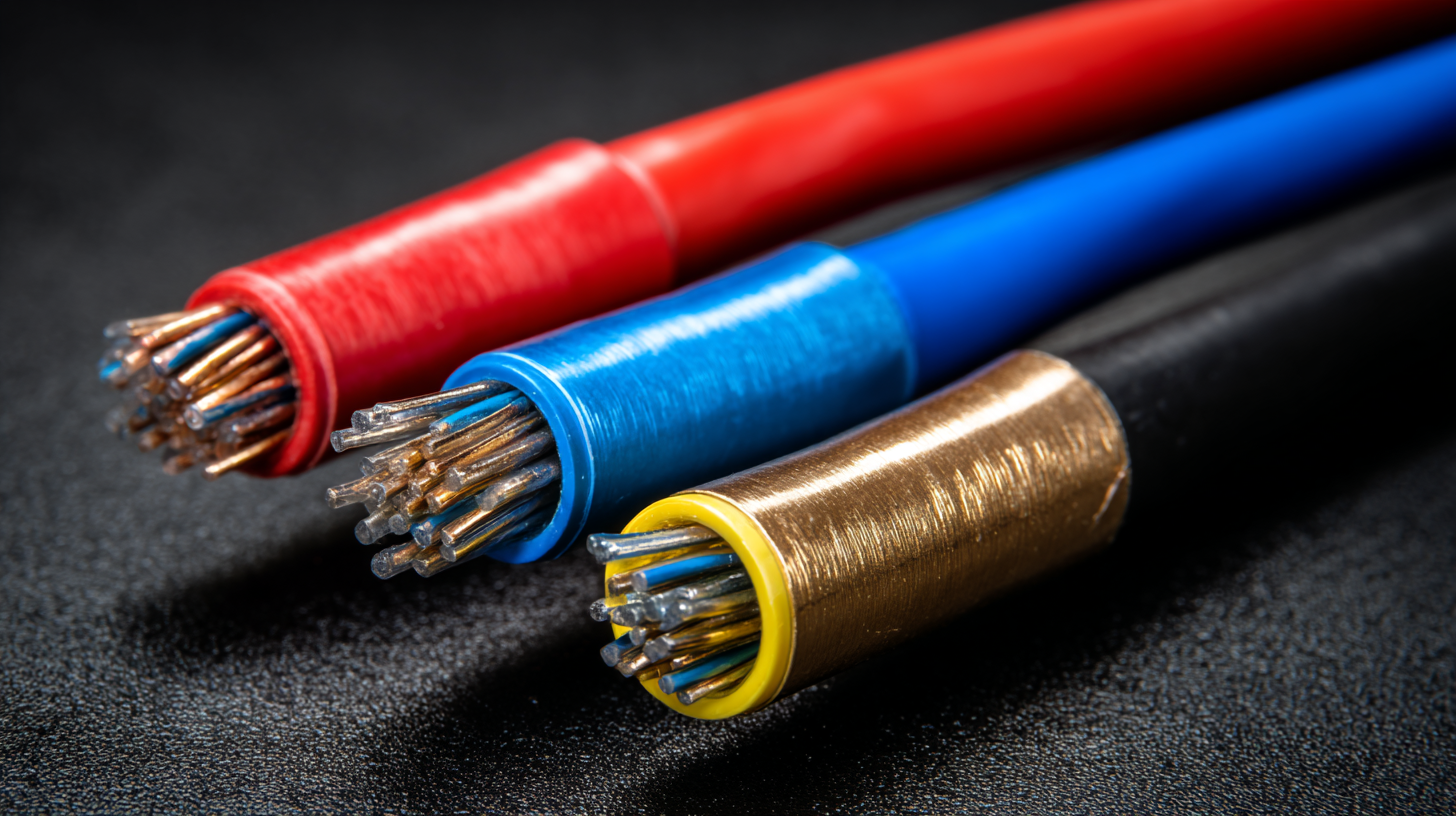

When selecting a micro coaxial cable for your application, several critical factors must be considered to ensure optimal performance. Firstly, the cable's diameter and flexibility are vital, particularly in environments where space is limited or flexibility is required. Micro coaxial cables come in various sizes, so it’s essential to match the cable to the specific needs of your project, especially in fields like data storage and transfer for artificial intelligence applications where compact designs significantly enhance system performance.

Another factor to consider is the cable's electrical specifications, including impedance, attenuation, and frequency response. For example, the global hybrid fiber coaxial market is projected to reach $18.3 billion by 2027, emphasizing the increasing demand for high-quality coaxial solutions in various industries. An appropriate selection of micro coaxial cables can facilitate efficient data transmission and significantly improve the reliability of systems, especially in rugged environments such as military applications where signal integrity is crucial. As technologies evolve, ensuring compatibility with modern standards, such as those required for advanced storage systems or medical devices, will also be fundamental in the decision-making process.

Understanding the Different Types of Micro Coaxial Cables

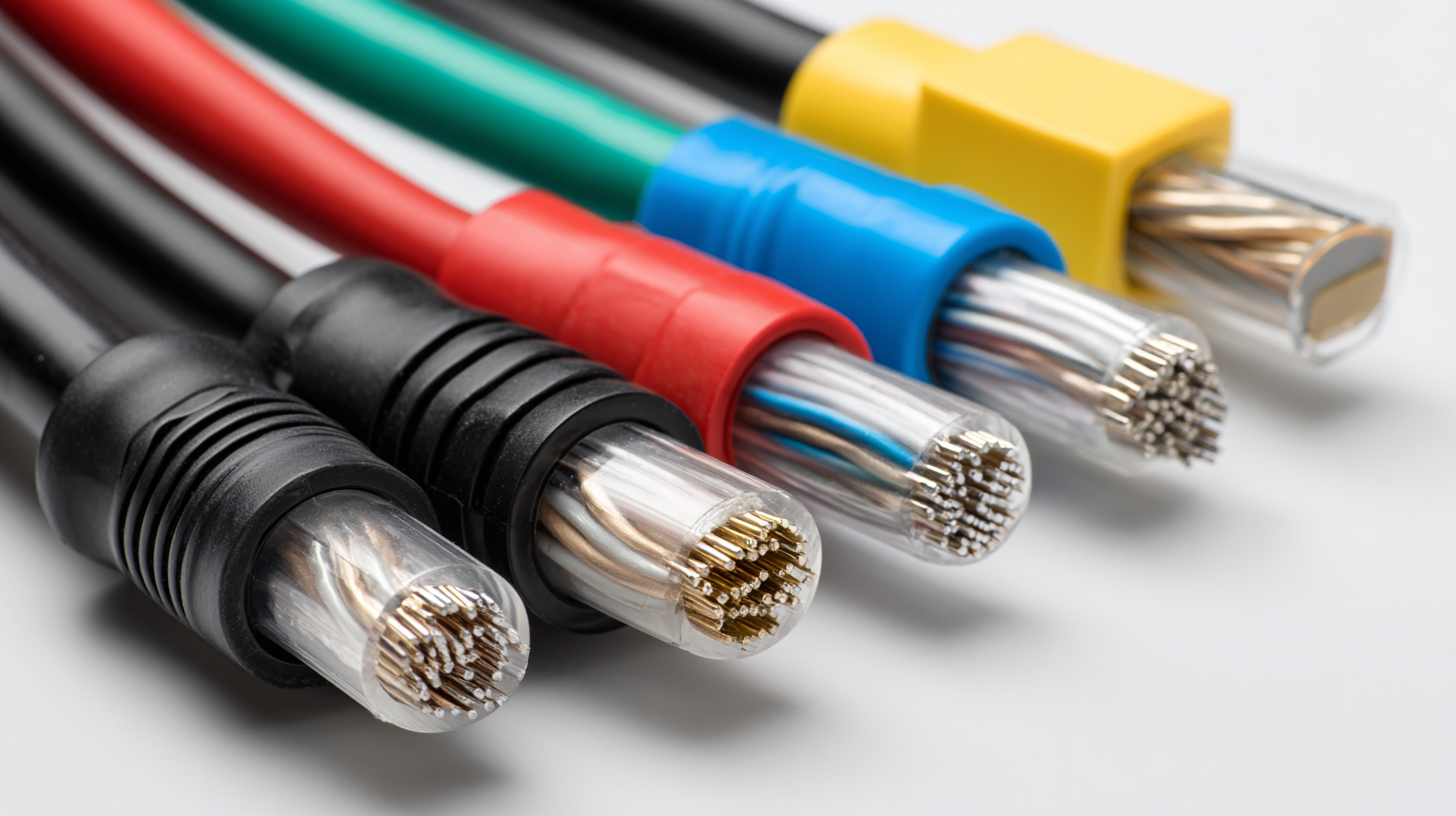

When selecting the right micro coaxial cable for your application, it's crucial to understand the different types available and their specific functionalities. Micro coaxial cables are designed for high-frequency signal transmission, making them a staple in applications such as telecommunications, medical devices, and aerospace systems. These cables come in various configurations, each tailored to meet unique signal integrity and environmental requirements.

For instance, in high-performance scenarios where minimizing signal delay is essential, low-skew twinax cables are worth considering. They reduce delay discrepancies, making them ideal for inside-the-box applications where every microsecond counts. Additionally, options like tightly coupled twinax cables provide enhanced performance metrics, including reduced impedance and insertion loss. With the continuing evolution of technology, especially in fields like wireless communications and sensor applications, choosing the right micro coaxial cable can significantly impact the efficiency and reliability of your systems. Understanding these selections can empower engineers to make informed decisions tailored to their specific operational demands.

Performance Specifications that Matter for Your Application

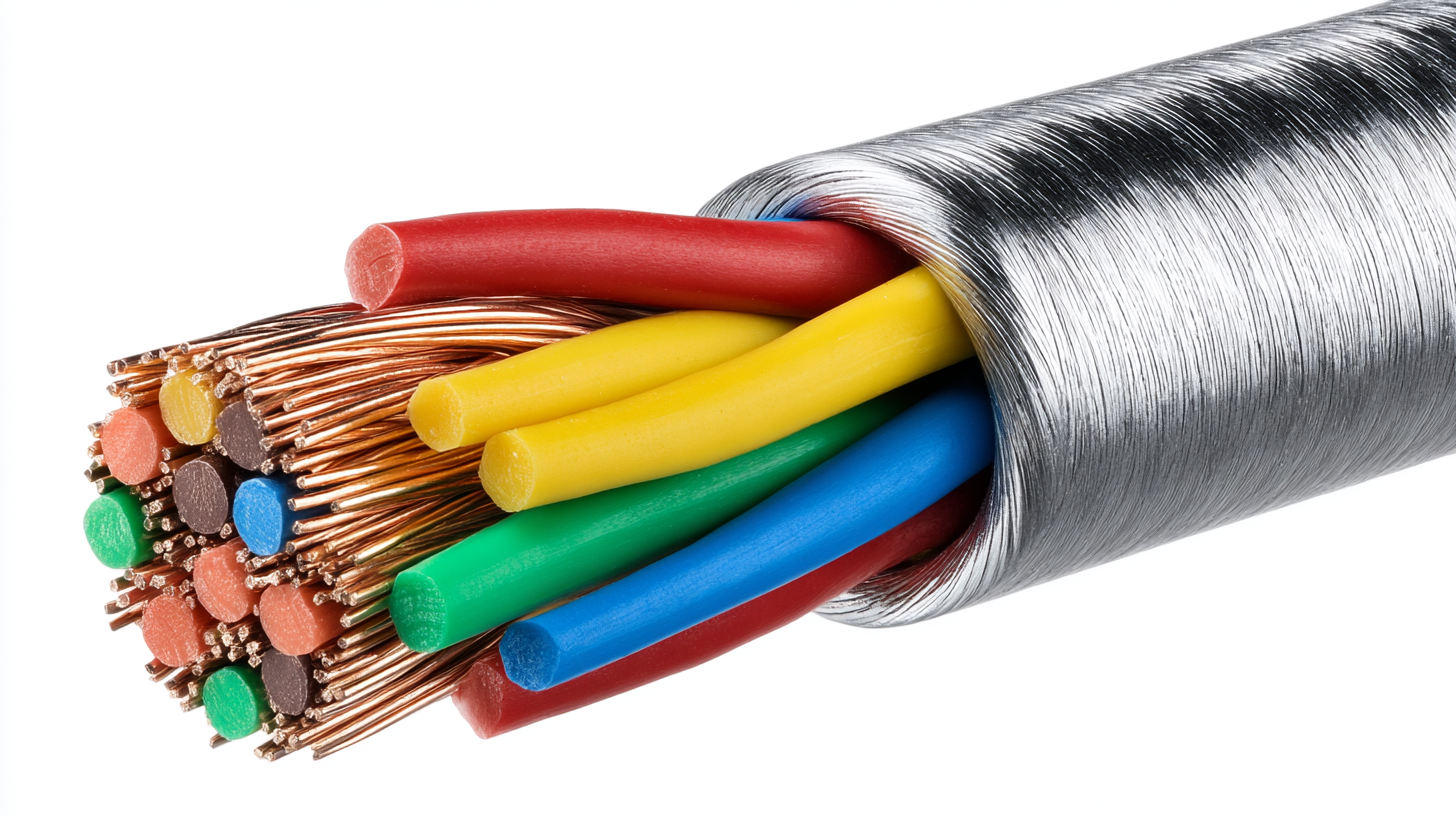

When selecting a micro coaxial cable for your application, understanding specific performance specifications is crucial. Key factors to consider include the cable's impedance, attenuation, and frequency range. For instance, a 50-ohm cable is typically preferred for RF applications, while a 75-ohm cable is suited for video and communication systems. Low attenuation is essential for long-distance signal transmission, as it minimizes the loss of signal strength, ensuring optimal performance in critical applications.

Additionally, the cable's flexibility and shielding options should not be overlooked, especially in environments that require bending or movement. A well-shielded cable can protect against electromagnetic interference, which is vital in sensitive electronic modules. Depending on the application, you might need cables with specific shielding configurations—like braided, foil, or a combination of both—to achieve the best results. By carefully evaluating these performance specifications, you can choose a micro coaxial cable that meets your unique requirements and enhances the reliability of your application.

Micro Coaxial Cable Performance Specifications

Common Applications of Micro Coaxial Cables in Various Industries

Micro coaxial cables have become increasingly crucial in various industries due to their compact size and superior performance. This technology is widely used in telecommunications, aerospace, and surveillance applications. For instance, the telecommunications sector benefits from these cables by facilitating high-speed data transmission in tight spaces, essential for maintaining connectivity in modern networks. The flexibility and reliability of micro coaxial cables directly impact the efficiency of communication systems, especially as the demand for data continues to surge.

As industries evolve, new innovative applications for micro coaxial cables are emerging. The global patch panels market is set to nearly double, growing from $1.28 billion in 2024 to $2.78 billion by 2032, with a compound annual growth rate (CAGR) of 10.19%. This growth is partly fueled by the rising adoption of micro coaxial cables in dynamic environments. For example, recent advancements in unmanned aerial vehicles (UAVs) highlight the growing utilization of these cables in the aerospace sector, where micro drones require reliable signal transmission for efficient operation in complex terrains. This illustrates the versatility and increasing importance of micro coaxial cables across multiple fields.

How to Choose the Right Micro Coaxial Cable for Your Application

| Industry | Common Applications | Recommended Cable Type | Typical Diameter |

|---|---|---|---|

| Telecommunications | Signal transmission for antennas | Micro Coaxial RG-178 | 1.13 mm |

| Medical | Connection for imaging devices | Micro Coaxial RG-316 | 1.37 mm |

| Consumer Electronics | Cameras and drones | Micro Coaxial RG-178A | 1.0 mm |

| Automotive | Sensor connections for ADAS | Micro Coaxial LMR-100 | 1.92 mm |

| Aerospace | Communication systems in aircraft | Micro Coaxial RG-402 | 1.85 mm |

Tips for Sourcing Quality Micro Coaxial Cables from Suppliers

When sourcing quality micro coaxial cables, it’s essential to consider various factors that ensure performance and reliability for your specific application. According to industry reports, the demand for high-speed signal transmission has surged, with micro coaxial cables becoming a staple in both consumer electronics and industrial applications. This has led to a variety of products flooding the market, making the selection process overwhelming.

To find the right supplier, look for manufacturers that adhere to stringent quality standards, such as ISO certifications. A study indicates that cables compliant with standard specifications show significantly lower failure rates, enhancing overall performance and durability. Additionally, consider the supplier's reputation and their ability to provide detailed product specifications, as this transparency often correlates with the quality of the products offered.

Furthermore, investing in cables that utilize advanced materials can lead to improved signal integrity and reduced interference. Reports show that using high-quality shielding and dielectric materials can minimize signal loss, maintaining optimal performance even in complex setups. By focusing on these critical factors, you can ensure that the micro coaxial cables you choose will meet the demands of your project and deliver the reliability that modern applications require.

Related Posts

-

Essential Guide to Understanding Twin and Earth Cable Specifications and Applications

-

Advantages of Choosing High Quality Electric Cable for Your Projects

-

7 Essential Factors Driving the Demand for High-Performance Trailer Cables in 2024

-

The Future of Underground Cable Conduit: Innovations Shaping Tomorrow's Infrastructure

-

Comprehensive Guide to Selecting the Best Flexible Cable Conduit for Your Project

-

Exploring Innovative Power Extension Cable Options for Every Need

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•