A partner you can trust

How to Choose the Right Flexible Cable Conduit for Optimal Electrical Safety

In today's electrical landscape, ensuring safety and efficiency is paramount, particularly when it comes to the selection of materials used in electrical installations. Flexible cable conduits play a crucial role in protecting electrical wires from environmental hazards, mechanical stress, and chemical exposure. According to a recent industry report by MarketsandMarkets, the global flexible conduit market is projected to reach over $1.2 billion by 2027, growing at a CAGR of 4.9%. This growth underscores the increasing reliance on flexible cable conduits in various applications, including residential, commercial, and industrial settings. Selecting the appropriate conduit is not only vital for regulatory compliance but also for maximizing the lifespan of electrical systems. By understanding the various types of flexible conduit materials and their specific applications, professionals can make informed choices that enhance electrical safety and operational efficiency.

Understanding the Importance of Flexible Cable Conduits in Electrical Safety

Flexible cable conduits play a crucial role in ensuring electrical safety. They provide protection for wiring in various environments, preventing damage from environmental factors such as moisture, dust, and physical impact. The U.S. electrical conduit market highlights the growing recognition of these conduits, valued at $1.72 billion in 2024 and expected to grow steadily. This upward trend reflects an increased emphasis on safety and compliance with updated regulations, including changes made in the 2023 National Electrical Code (NEC).

When selecting the right flexible cable conduit, consider the specific application and environment. Tip 1: Choose a conduit that meets the relevant safety standards for your location and intended use. This ensures compliance with the NEC and enhances safety measures. Tip 2: Evaluate the flexibility and durability of the conduit material; a high-quality conduit should withstand environmental stressors while maintaining ease of installation. With careful selection, you can better safeguard electrical systems and reduce potential hazards.

In addition, keep abreast of local code changes and industry best practices. Tip 3: Regularly consult the updated codes and guidelines to ensure your installations remain compliant and secure over time. Staying informed helps in making sound decisions that bolster electrical safety.

Identifying Different Types of Flexible Cable Conduits and Their Applications

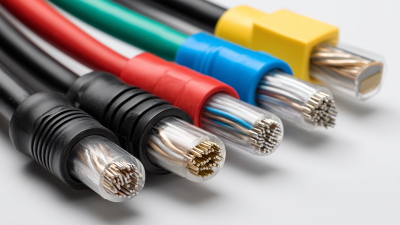

When selecting the right flexible cable conduit, it’s essential to understand the various types available and their specific applications. Flexible cable conduits come in several materials, including PVC, nylon, and metal. PVC conduits are ideal for indoor applications due to their resistance to moisture and chemicals. In contrast, nylon conduits offer excellent flexibility and are suitable for environments with extreme temperatures. Metal conduits, such as steel or aluminum, are robust options often used in industrial settings where additional protection is required.

Tip: Always consider the environment where the conduit will be installed. For areas exposed to high temperatures or corrosive substances, opt for materials designed for those conditions.

Another key factor in choosing a flexible cable conduit is its diameter and the number of cables it needs to accommodate. Selecting the correct size ensures optimal cable protection and ease of installation. Too tight a fit can damage the cables, while an overly spacious conduit may allow excessive movement that leads to wear.

Tip: Measure the cables you plan to protect and choose a conduit with a diameter that allows for a snug fit without excessive pressure.

Factors to Consider When Selecting Flexible Cable Conduits for Specific Environments

When selecting flexible cable conduits for specific environments, several critical factors must be considered to ensure optimal electrical safety. Firstly, the environmental conditions play a significant role. For instance, areas that are exposed to extreme temperatures, moisture, or corrosive substances necessitate conduits made from materials that can withstand such conditions without compromising their integrity. Choosing conduits made from high-quality thermoplastics or metal can enhance durability and protect cables from environmental hazards.

Additionally, the flexibility of the conduit should align with the installation requirements of the project. In spaces with complex layouts or areas where cables need to navigate around obstacles, opting for a highly flexible conduit can ease installation and maintenance. It is also essential to consider the application of the electrical system; conduits intended for industrial use may need to comply with specific safety standards and regulations to mitigate risks associated with heavy machinery or hazardous environments. Understanding these factors is crucial for selecting the right conduit that ensures both safety and functionality in diverse operational contexts.

Steps to Ensure Proper Installation and Maintenance of Flexible Cable Conduits

When installing flexible cable conduits, proper execution is crucial for ensuring electrical safety and reliability. Begin by selecting a conduit that is compatible with the specific environment and electrical applications. Consider factors such as temperature, exposure to chemicals, and mechanical stresses that may affect the conduit’s performance. Once the appropriate conduit is selected, ensure that all fittings and connectors are rated for the conduit type to maintain a secure and effective installation.

During installation, it is essential to adhere to local electrical codes and standards. Begin with a clean and dry surface to prevent any contaminants from compromising the integrity of the conduit. Secure the conduit at regular intervals to minimize movement and potential damage. After installation, a periodic maintenance check is vital to ensure that the conduits remain intact and functional. Inspect for wear, corrosion, or other signs of deterioration, and replace any compromised sections promptly. This routine maintenance not only extends the lifespan of the conduits but also upholds the safety of the electrical systems they protect.

Regulatory Standards and Compliance for Flexible Cable Conduit Usage in Electrical Systems

When selecting flexible cable conduits for electrical systems, regulatory standards and compliance play a crucial role in ensuring safety and reliability. According to the National Electrical Code (NEC), the use of flexible conduits must adhere to specific guidelines that define the material quality, installation methods, and application contexts. For instance, products like Liquidtight Flexible Nonmetallic Conduit (LFNC) are required to meet UL 1660 standards, which guarantee protection against moisture and facilitate installation in diverse environments. Failure to comply with these standards can lead to significant safety hazards, including electrical fires or equipment damage.

Moreover, a report by the International Electrotechnical Commission (IEC) stressed the importance of using certified conduits that comply with IEC 61386, which outlines performance criteria for conduits including mechanical strength, thermal resistance, and ingress protection. This compliance not only prevents electrical shock risks but also promotes longevity in electrical installations, minimizing maintenance costs over time. Adhering to these regulatory frameworks is vital for any electrical engineering project aiming for optimal safety and operational efficiency.

Flexible Cable Conduit Compliance Standards

This chart illustrates the compliance levels of different flexible cable conduit types against regulatory standards in electrical systems, based on the latest industry data.

Related Posts

-

Understanding the Benefits of Using Flexible Cable Conduit in Your Projects

-

7 Essential Factors Driving the Demand for High-Performance Trailer Cables in 2024

-

How to Choose the Right Micro Coaxial Cable for Your Application

-

Top Strategies for Sourcing Shielded Power Cable in Global Markets

-

Essential Guide to Understanding Twin and Earth Cable Specifications and Applications

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•