A partner you can trust

How to Choose the Right XLPE Insulated Power Cable for Your Needs?

Choosing the right XLPE insulated power cable can significantly impact your project's success. This type of cable is designed for high performance and durability. However, many factors can complicate your choice.

Understanding your specific needs is crucial. Consider the voltage levels and environmental conditions. For instance, cables in wet areas require additional protection. The XLPE insulated power cable stands out due to its excellent thermal resistance. It performs well in extreme temperatures.

However, selecting the right cable isn’t always straightforward. Misinformation about specifications may lead to poor choices. Reflect on your long-term requirements. What may seem suitable now may not suffice down the road. Making an informed decision demands careful thought and research.

Understanding XLPE Insulated Power Cables: Key Features and Benefits

XLPE (cross-linked polyethylene) insulated power cables are becoming increasingly popular in various electrical applications. These cables offer a range of key features that make them a preferred choice for installations. One major benefit is their high resistance to heat and chemicals. This means they can perform well in harsh environments. The insulation material allows for higher operating temperatures, reducing the risk of damage.

Another important feature is their excellent dielectric properties. This contributes to improved energy efficiency during operation. Additionally, XLPE cables have a greater capacity to carry electrical loads. This makes them suitable for industrial applications that require reliability and durability. However, these advantages do not come without considerations. Proper installation is crucial to maximize performance. Mistakes during the installation process can lead to issues in the long run.

Moreover, while XLPE cables offer flexibility, choosing the right size and rating can be challenging. Oversizing can lead to unnecessary costs, while undersizing may result in overheating. System demands vary widely. It’s important to assess these demands carefully. Potential buyers should consult with professionals to ensure the best match for their needs. Making informed choices can save time and resources down the line.

Assessing Your Power Requirements: Determining the Right Cable Specifications

When selecting XLPE insulated power cables, understanding your power requirements is crucial. Start by determining the total load that the cable will serve. Calculate the wattage for each device or appliance connected to the system. This helps in deciding the appropriate cable size. For example, a small office may need less capacity than a manufacturing facility.

Also consider the distance between the power source and the load. Longer distances can lead to voltage drops, which may affect performance. It’s essential to ensure that the cable can maintain its efficiency over the required length. Sometimes, users forget to account for ambient temperature and installation conditions. These factors can also influence cable performance.

Moreover, the type of insulation matters. While XLPE is known for its thermal properties, it might not be ideal for every environment. Assessing environmental factors can be complex. For instance, extreme temperatures or exposure to chemicals can affect cable longevity. It’s vital to reflect on these aspects to avoid future issues. Ignoring these details may lead to inadequate performance and costly repairs later.

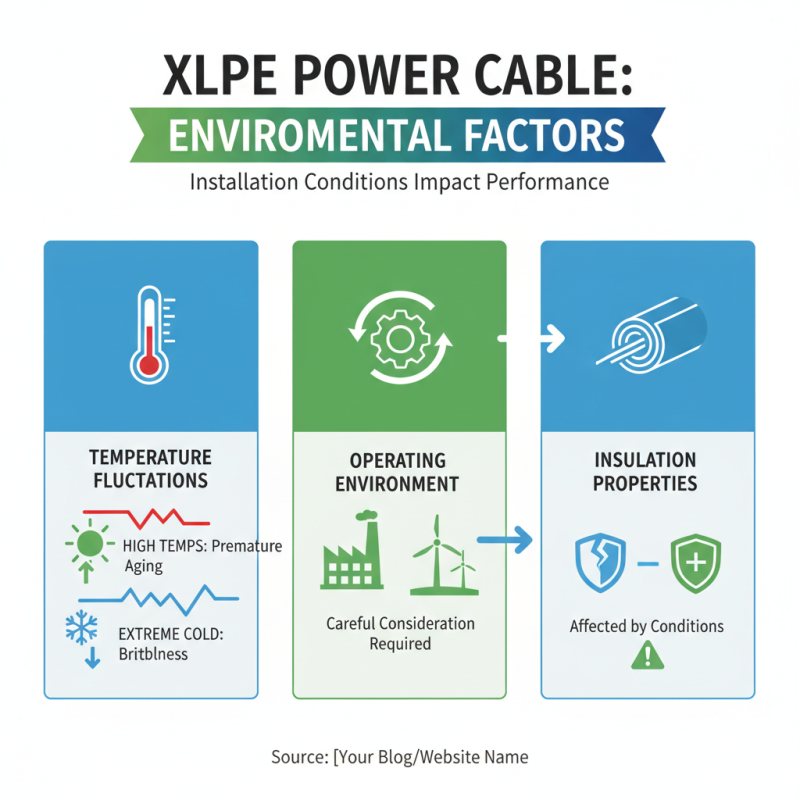

Environmental Factors: Matching XLPE Cables to Your Installation Conditions

When selecting XLPE insulated power cables, environmental factors play a crucial role. The installation conditions impact cable performance significantly. For example, temperature fluctuations can affect insulation properties. High temperatures may lead to premature aging, while extreme cold can make cables brittle. These situations require careful consideration of the operating environment.

Moisture is another environmental factor to consider. Areas with high humidity can accelerate insulation degradation. Thus, using cables with enhanced water resistance becomes essential. Additionally, exposure to chemicals can corrode cable materials. This requires thorough evaluation of the surrounding substances to prevent future failures.

Considering the location is vital. Underground installations may demand different specifications than overhead lines. Poor soil conditions can also affect durability. It's important to evaluate soil resistance and potential electrical interference. Failure to address these factors can lead to costly repairs and operational downtime. Understanding the installation site is a step toward a successful project.

Evaluating Cable Construction: Importance of Armor and Sheathing

When selecting XLPE insulated power cables, the cable's armor and sheathing play crucial roles. Armor adds physical protection against mechanical damage. It also provides a level of shielding from electromagnetic interference. This is vital in environments with heavy machinery or vibrations. The choice of materials for the armor can significantly affect performance. Steel, aluminum, or composite options each have distinct benefits and weaknesses.

Sheathing, on the other hand, offers insulation from environmental factors. It guards against moisture, chemicals, and abrasion. The right sheathing enhances the cable's lifespan and reliability. Yet, it's not always easy to determine which materials are most suitable for specific conditions. A common mistake is assuming that thicker sheathing is always better. This can add unnecessary weight and impact installation.

Evaluating these features requires careful consideration of the installation environment. Inspection of local conditions, such as temperature extremes and exposure to chemicals, is essential. Underestimating these factors can lead to premature cable failure. Understanding the balance between protection, flexibility, and weight is vital. It might require experimenting with different options to find the best fit.

Comparing Brands and Standards: Choosing Reliable Manufacturers for XLPE Cables

When selecting XLPE insulated power cables, understanding brands and standards is crucial. According to the International Electrotechnical Commission (IEC), quality variations can significantly impact performance and safety. Cables must adhere to specific standards, like IEC 60502-1 and IEC 60076. These standards outline the requirements for design and testing, ensuring reliability and longevity.

Manufacturers who meet these regulations often undergo rigorous testing. Industry reports indicate that cables tested under these standards show a failure rate of less than 2%. This number highlights the importance of choosing reliable manufacturers. However, not all brands prioritize compliance. Some may cut corners to reduce costs, leading to higher failure rates.

Additionally, consider the environmental impact. XLPE cables have lower environmental risks compared to PVC cables. They are more resistant to heat and have excellent dielectric properties. Despite their advantages, some manufacturers may still use subpar materials in their production. Always verify certifications and performance records. This practice will help reduce the risk of issues later on.

Related Posts

-

Exploring Cooker Cable Innovations at the 2025 China Import and Export Fair

-

Exploring the Future of Wire and Cable Technology Innovations in Connectivity

-

Top Electrical Cable Tray Types: Which One is Right for Your Project?

-

How to Choose the Best Multi Cable Charger for Your Devices: Key Features and Expert Insights

-

Ultimate Guide to Choosing the Right Power Extension Cable for Your Needs

-

Exploring the Benefits of Shielded Power Cable for Enhanced Electrical Performance

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•