A partner you can trust

How to Choose the Right Wire and Cable for Your Electrical Projects

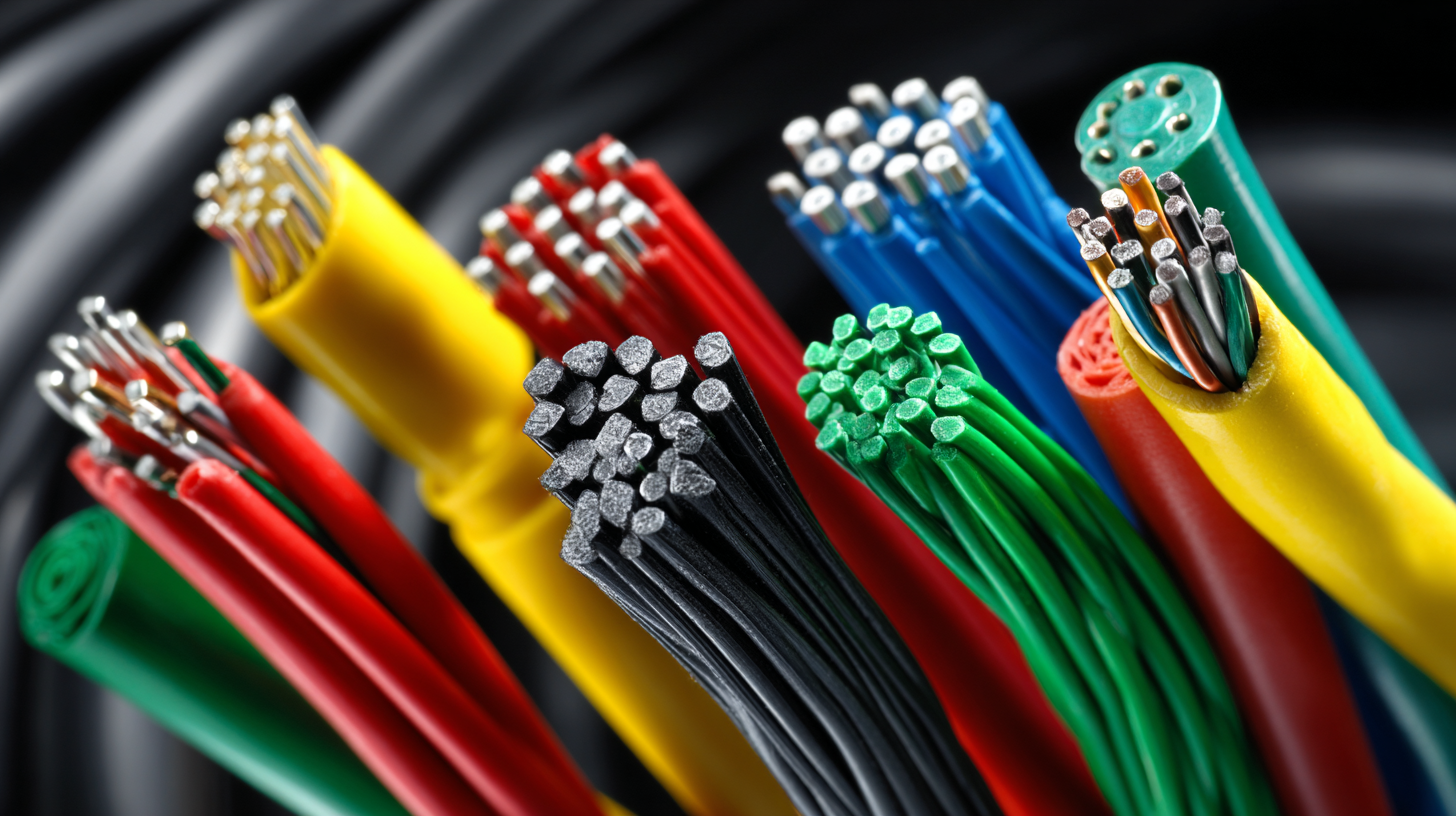

When embarking on any electrical project, one of the most critical decisions you will face is selecting the appropriate wire and cable. The global wire and cable market was valued at approximately $206 billion in 2022, and it is projected to reach $307 billion by 2030, according to a report by Fortune Business Insights. This staggering growth underscores the importance of understanding the various types of wire and cable available and their specific applications.

Choosing the right materials not only ensures safety and compliance with industry standards but also enhances the efficiency and longevity of electrical systems. With the myriad of options ranging from low-voltage to high-voltage cables and specialized wires for unique environments, this guide will provide essential insights and criteria to help you make informed decisions tailored to your project’s demands.

Understanding Different Types of Wires and Cables for Electrical Projects

When undertaking electrical projects, selecting the appropriate wire and cable is crucial for safety and efficiency. Understanding the different types available can help ensure your project runs smoothly. For general indoor wiring, THHN (Thermoplastic High Heat-resistant Nylon-coated) wire is commonly used due to its flexibility and durability. For outdoor applications or areas exposed to moisture, consider using UF (Underground Feeder) cable, which is designed to withstand environmental stress and is waterproof.

When undertaking electrical projects, selecting the appropriate wire and cable is crucial for safety and efficiency. Understanding the different types available can help ensure your project runs smoothly. For general indoor wiring, THHN (Thermoplastic High Heat-resistant Nylon-coated) wire is commonly used due to its flexibility and durability. For outdoor applications or areas exposed to moisture, consider using UF (Underground Feeder) cable, which is designed to withstand environmental stress and is waterproof.

Tips: Always check the ampacity of the wire to ensure it can handle the electrical load of your project. Using wire that is too small for your application can result in overheating and potential fire hazards. Additionally, when working with specialized applications like homes with high-tech electrical systems, be aware of options like low-voltage wires for control purposes and avoid overcomplicating your setup.

Another important factor is insulation type. Most wires come with varying insulation that protects against high temperatures and moisture. Consider using PVC insulation for standard applications, while silicone insulation is ideal for high-temperature environments. Choosing the right insulation helps to prolong the lifespan of your wiring and ensures safe operation of your electrical systems.

Key Factors to Consider When Selecting Wire Gauge for Your Needs

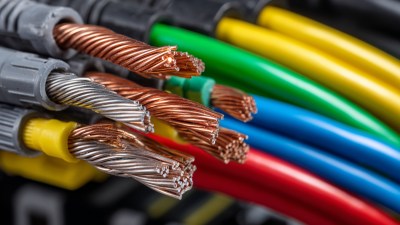

When selecting the appropriate wire gauge for your electrical projects, several key factors come into play. The capacity of the wire to handle current without overheating is paramount. Understanding your project's voltage and amperage requirements will guide you to the right wire gauge. For instance, a lower gauge number indicates a thicker wire capable of carrying higher currents, which is essential for safety and efficiency.

Tips: Always consult the National Electrical Code (NEC) for guidelines on wire sizing relative to the specific application. If dealing with renewable energy systems, consider using wires designed for outdoor use that can withstand environmental factors. Additionally, calculating the distance between your power source and the load is crucial; longer distances may necessitate a thicker wire to minimize voltage drop, ensuring optimal performance.

Another aspect to consider is the type of insulation needed based on your project's environment. For projects in wet or harsh conditions, choose cables with appropriate insulation ratings. This choice not only protects against moisture but also contributes to the longevity of your electrical system, especially when integrating renewable energy sources that demand reliable performance.

Evaluating Insulation Materials: What You Need to Know

When selecting wire and cable for electrical projects, the insulation material plays a critical role in ensuring performance and longevity. Different insulation materials offer varying degrees of thermal resistance, moisture protection, and chemical durability. According to the "Wire and Cable Manufacturing Industry Report" by the National Electrical Manufacturers Association (NEMA), polyvinyl chloride (PVC) remains the most widely used insulation type due to its balance of affordability and versatility across a range of applications. However, for projects requiring higher temperature resistance, materials such as polyethylene or thermoplastic elastomers are recommended, providing performance in temperatures up to 90°C or higher.

Moreover, environmental conditions can significantly impact the choice of insulation. The "2023 Electrical Insulation Guide" indicates that in outdoor applications, UV and ozone resistance are crucial. Here, cross-linked polyethylene (XLPE) is often favored due to its excellent resistance to environmental stressors and superior electrical properties. When evaluating the right insulation material, it’s essential to consider the specific operational demands as well as regulatory compliance, ensuring that the selected materials meet the rigorous standards set by organizations such as Underwriters Laboratories (UL) and the International Electrotechnical Commission (IEC). Understanding these factors will equip you to make informed decisions that enhance safety and reliability in your electrical projects.

Safety Standards and Regulations for Electrical Wiring

When embarking on electrical projects, understanding safety standards and regulations is paramount. The National Electrical Code (NEC), which provides minimum safety standards for electrical installations in the U.S., is a critical resource. According to the NEC, wiring must not only be appropriate for the voltage and current it will carry but also compliant with local regulations. For instance, using the right gauge of wire is essential; a wire that is too thin can overheat, leading to electrical fires. The NEC stipulates that for general residential wiring, 14-gauge wire is typically used for circuit breakers of up to 15 amps, while 12-gauge wire is recommended for 20 amps.

Moreover, the Occupational Safety and Health Administration (OSHA) outlines crucial safety practices for electrical work. These include proper installation techniques, the use of personal protective equipment, and adhering to environmental regulations. A report from the U.S. Fire Administration indicates that electrical fires account for approximately 6% of all U.S. residential fires, underscoring the importance of compliance with these safety standards. By staying informed about the NEC and OSHA guidelines, electricians can significantly reduce risks and enhance safety in their projects.

Tips for Sourcing High-Quality Wires and Cables for Your Projects

When sourcing high-quality wires and cables for your electrical projects, it’s essential to consider several key factors to ensure safety, efficiency, and longevity. A report by the National Electrical Manufacturers Association (NEMA) indicates that the market for electrical wires and cables is expected to grow at a CAGR of 5.6% from 2021 to 2026, driven by rising demand in construction and renewable energy sectors. This growth underscores the importance of selecting the right materials to meet stringent industry standards and regulations.

One critical aspect to focus on is the material composition of the cables. According to the International Electrotechnical Commission (IEC), copper and aluminum are the primary materials for electrical wires. Copper offers superior conductivity and durability but can be more expensive than aluminum, which, despite being lighter and less costly, may require larger conductors to achieve similar performance levels. Additionally, ensuring compliance with relevant certifications, such as UL or IEC standards, can significantly enhance the reliability of your wiring solution. Choosing vendors that provide transparent documentation of their product’s specifications and testing ensures that the cables will perform efficiently in their intended applications.

Related Posts

-

Advantages of Choosing High Quality Electric Cable for Your Projects

-

What is the Importance of Wire Cable in Modern Electrical Systems

-

How to Choose the Right Electric Cable for Your Global Procurement Needs

-

Top Strategies for Sourcing Shielded Power Cable in Global Markets

-

Essential Guide to Understanding Twin and Earth Cable Specifications and Applications

-

7 Essential Factors Driving the Demand for High-Performance Trailer Cables in 2024

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•