A partner you can trust

How to Choose XLPE Insulated Power Cables for Your Project?

Choosing the right xlpe insulated power cable for your project is crucial. These cables have become increasingly popular due to their superior properties. According to recent industry reports, the demand for xlpe insulated power cables has surged by 15% annually. This growth highlights their importance in modern electrical systems.

XLPE cables offer excellent thermal resistance and are resistant to moisture. They can handle higher voltage levels effectively. Data indicates that xlpe cables can operate at temperatures up to 90°C, making them suitable for various applications. However, not all projects require the same specifications. Understanding your project's needs is vital.

While xlpe cables are durable, their installation can be challenging. It’s necessary to focus on proper installation techniques to avoid costly errors. Regularly evaluating your choices can lead to better outcomes. Selecting the right xlpe insulated power cable requires careful consideration. Don’t overlook the specifics of your project.

Understanding XLPE Insulated Power Cables and Their Benefits

XLPE (cross-linked polyethylene) insulated power cables offer numerous advantages over traditional cable types. They can withstand higher temperatures, making them suitable for a variety of environments. According to industry reports, these cables can operate effectively at temperatures up to 90°C, while standard PVC cables typically max out around 70°C. This characteristic allows for better performance in demanding applications.

The benefits of XLPE cables extend beyond temperature tolerance. Their resistance to moisture and chemicals makes them ideal for harsh conditions. Data shows that XLPE cables have a significantly lower incidence of failure in challenging environments. For instance, the lifespan of these cables often exceeds 30 years with proper installation and maintenance. This longevity can lead to reduced replacement costs and less downtime.

While XLPE insulated cables are robust, installation must be done with care. Improper handling can lead to damage, negating their advantages. It is crucial to follow manufacturer guidelines and industry best practices during installation. Also, consider factors like installation environment and load demands to maximize performance. Balancing these elements is key to ensuring reliability in your project.

How to Choose XLPE Insulated Power Cables for Your Project?

| Parameter | Description | Benefits |

|---|---|---|

| Material | Cross-linked Polyethylene (XLPE) | Superior thermal resistance and electrical properties. |

| Voltage Rating | Up to 36 kV or more | Suitable for high voltage applications. |

| Temperature Range | -40°C to 90°C | Operating in extreme environmental conditions. |

| Cable Type | Single-core, Multi-core | Flexibility in installation based on project requirements. |

| Fire Resistance | Low fire propagation | Enhanced safety in case of fire. |

| Application | Industrial, commercial, utility | Versatile usage across multiple sectors. |

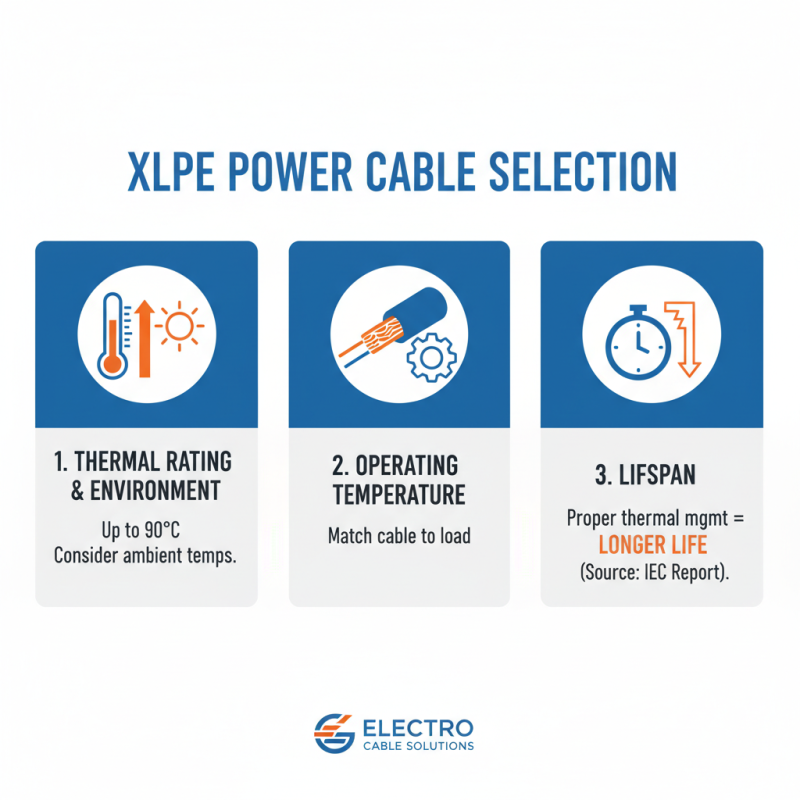

Key Factors to Consider When Selecting XLPE Cables

When selecting XLPE insulated power cables for your project, several factors play a crucial role. The thermal rating of the cables is critical. Understanding the operating temperature is key. XLPE cables can operate at up to 90°C, but environmental conditions vary. A report from the International Electrotechnical Commission (IEC) states that improper thermal management could reduce cable lifespan.

Consider the voltage rating as well. Ensure that the cable can handle the operational voltage of your system. Typically, the required voltage ratings for XLPE cables range from 0.6/1 kV to 35 kV. Also, pay attention to the cable's current-carrying capacity. Some projects may face unexpected loads, which can lead to cable overheating. The Institute of Electrical and Electronics Engineers (IEEE) emphasizes that ignoring these can result in costly failures.

Lastly, installation conditions matter significantly. The cable’s resistance to moisture and chemicals is crucial for longevity. Difficulty in installation can lead to damages later. Visual inspections during installation often get overlooked. This impacts performance. Choosing the right XLPE insulated cable requires careful evaluation of these details. Balancing all factors is vital, yet it’s easy to overlook some technical aspects.

Evaluating Cable Specifications and Ratings for Your Project

When selecting XLPE insulated power cables, understanding cable specifications is crucial.

Voltage rating is one key specification. Cables typically range from 0.6/1kV to 36kV in voltage ratings.

Higher voltage ratings may seem ideal, but they can increase system complexity.

Assess the requirements of your project carefully.

Consider the current-carrying capacity as well. This capacity can vary based on ambient temperature,

installation conditions, and whether the cables are buried or in the open air.

A recent industry report suggests that miscalculating this can lead to overheating.

Cables with low current ratings could fail prematurely, causing project delays.

Also, pay attention to insulation thickness. Standards indicate that thicker insulation improves durability but adds cost.

An inadequate thickness may lead to increased electrical losses.

Balancing these factors is often challenging. Decision-making requires meticulous consideration.

Look at industry benchmarks for guidance, but always adapt to specific project needs.

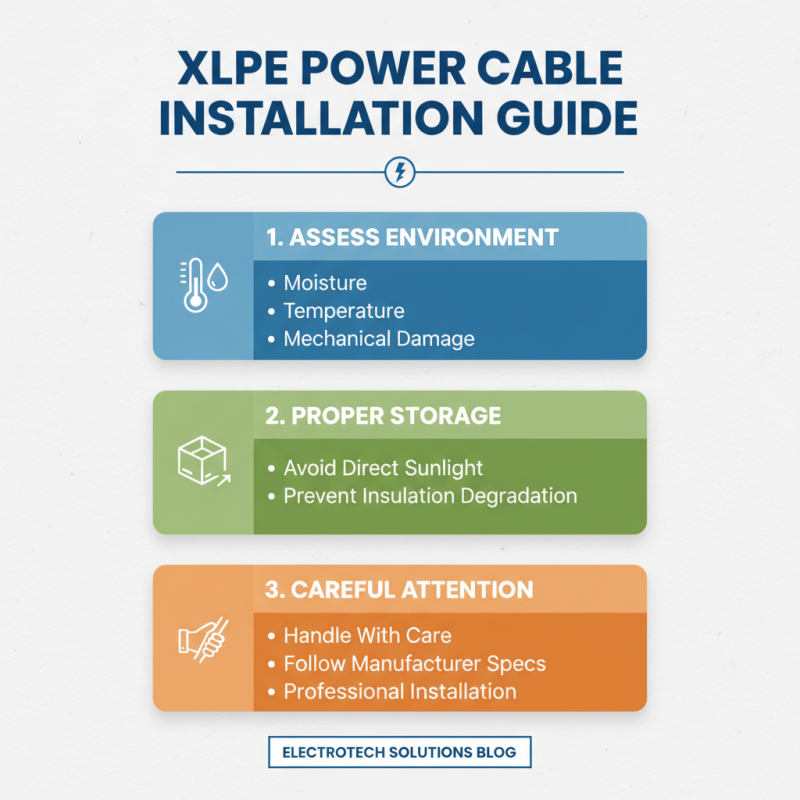

Installation and Handling Guidelines for XLPE Insulated Cables

Installing XLPE insulated power cables requires careful attention. Begin by assessing the environment where the cables will be installed. Consider factors such as moisture, temperature, and potential mechanical damage. Proper storage is key. Avoid exposing the cables to direct sunlight before installation. This can degrade the insulation over time.

During installation, maintain appropriate bending radii. Excessive bending can cause damage and affect cable performance. Use the right tools to avoid damaging the insulation. It’s helpful to clean the installation site. Clear debris ensures a smoother process. Always wear protective gear when handling cables.

Once installed, regular inspections are essential. Check for signs of wear or damage. Pay attention to joints and connections as they are often points of failure. Make adjustments as needed. If issues arise, reassess installation methods. Learning from each project can enhance future installations. It's a process that often requires reflection and adjustment.

Common Applications and Best Practices for XLPE Power Cables

When selecting XLPE insulated power cables, understanding their applications is crucial. These cables are commonly used in industrial settings, power generation, and distribution. They excel in environments where moisture and chemical exposure are prevalent. According to the International Electrotechnical Commission (IEC), XLPE cables can handle temperatures up to 90°C, making them suitable for demanding conditions.

Tips: Always consider the ambient temperature and installation conditions. A mismatch can lead to cable failure.

In urban developments, these cables are often used underground. This provides protection and minimizes visual impact. Reliability and longevity are key. Data from the Electric Power Research Institute (EPRI) indicates that XLPE cables can have a lifespan of over 30 years. However, installation mistakes can compromise their performance.

Tips: Ensure proper installation techniques are followed. Incorrect bending radii can damage cables.

Furthermore, although XLPE cables are highly efficient, their cost may be a concern. Choosing the right supplier and sourcing can significantly impact your project budget. A thorough analysis of lifecycle costs is essential. Balancing quality with cost-effectiveness requires careful consideration. The long-term savings of investing in XLPE may outweigh initial expenses.

Common Applications of XLPE Insulated Power Cables

Related Posts

-

How to Choose the Right XLPE Insulated Power Cable for Your Needs?

-

Exploring the Benefits of Shielded Power Cable for Enhanced Electrical Performance

-

Advantages of Choosing High Quality Electric Cable for Your Projects

-

How to Choose the Best EV Ultra Cable for Your Electric Vehicle Charging

-

Understanding the Impact of Electric Cable Quality on Energy Efficiency and Safety in Modern Infrastructure

-

The Ultimate Guide to Choosing the Best Outdoor Electrical Cable in 2025

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•