A partner you can trust

Essential Tips for Choosing Tray Cable Wire for Your Project?

Choosing the right tray cable wire is crucial for any electrical project. According to industry expert Mark Thompson, "Selecting quality wire ensures safety and efficiency." Tray cables are used in various applications. They offer flexibility and durability, but not all are created equal.

When selecting tray cable wire, consider factors like the environment and load. Different materials offer varying levels of resistance and flexibility. For instance, PVC insulation may not perform well in extreme temperatures. This can lead to potential failures over time.

It's essential to reflect on your project's specific needs. Overlooking these details can lead to costly mistakes. Prioritizing quality will always pay off. Remember, the right tray cable wire guarantees safety and longevity in your installations.

Understanding Tray Cable Wire Specifications and Types

When selecting tray cable wire for your project, understanding specifications is key. Tray cable wire comes in various types, each designed for specific applications. The most common types are TC, TC-LH, and TC-ER. Each type has unique attributes, such as temperature ratings and environmental resistance. For instance, TC-LH is suitable for high temperatures, while TC-ER can be used outdoors.

Additionally, wire gauge matters greatly in selection. The larger the gauge number, the smaller the diameter. A heavy gauge might seem like a safe bet, but it can be more challenging to install. Be wary of overestimating your needs. For some projects, a smaller gauge may suffice, saving money and installation time. Inadequate knowledge can lead to poor choices; understanding load requirements is essential.

Don’t overlook shielding options, especially in environments with heavy machinery. Shielded cables help reduce electromagnetic interference, ensuring better performance. Picking the right insulation type is equally critical. PVC is common, but it may not suit all climates. In harsh environments, consider thermoset materials. Taking time to evaluate the specific needs of your project can prevent costly mistakes down the line.

Tray Cable Wire Types and Their Applications

Evaluating the Environment for Proper Tray Cable Wire Selection

When selecting tray cable wire for a project, evaluating the environment is crucial. The installation site can greatly impact performance. Different conditions, such as temperature, moisture, and exposure to chemicals, require specific wire types. Ideally, you want a wire that withstands your local conditions without significant degradation over time.

For example, if you live in a humid area, choosing wires with better moisture resistance is necessary. In contrast, exposure to chemicals demands cables with robust insulation. Reflect on the real-life scenarios your installation might face during its lifespan. What if a sudden storm causes flooding? Will your cable stand the test?

Also, consider the cable's flexibility. Rigid wires may not adapt well to changing conditions. Installation environments can be unpredictable. It's beneficial to plan for the worst-case scenario, even if it seems excessive. Often, cables must move through tight spaces, making flexibility essential. Balancing all these factors is not easy, but it's vital for ensuring long-lasting performance.

Essential Tips for Choosing Tray Cable Wire for Your Project

| Criteria | Description | Recommended Type | Environmental Considerations |

|---|---|---|---|

| Cable Type | Determine if you require unshielded, shielded, or armored cable based on application needs. | Type TC (Tray Cable) | Ensure compatibility with environmental factors such as moisture and dust. |

| Voltage Rating | Identify the voltage requirements of your installation to choose suitable cables. | 600V or 1000V Rated | Higher voltage ratings may be necessary for industrial applications. |

| Conductor Material | Select between copper or aluminum conductors based on conductivity and budget. | Copper | Copper is ideal for environments requiring higher efficiency and durability. |

| Temperature Rating | Check the operational temperature range suitable for the location of the installation. | 90°C (with an appropriate insulation) | Consider outdoor versus indoor use and temperature extremes. |

| Cable Length | Measure the distance to ensure the selected cable length meets installation needs. | Custom lengths available | Factor in ampacity and voltage drop over longer distances. |

Determining the Correct Wire Gauge for Your Project Needs

Choosing the right wire gauge is crucial for any project involving tray cable. The gauge affects the wire's capacity to handle electrical load. If the gauge is too small, wires may overheat. This can lead to failures or hazards. Larger gauges can manage higher currents but are often more difficult to handle.

When selecting a wire gauge, consider the distance of wire runs. Longer distances may require thicker wire to avoid voltage drop. Calculate the total current your project will use. Always err on the side of caution. It’s safer to go a gauge higher if unsure. This ensures you have enough capacity for unexpected loads.

Tips: Always check local codes and regulations. They may dictate specific wire sizes for certain tasks. Additionally, think about the environment where the wire will be used. Exposure to moisture or heat may also influence your choice. Design your project with flexibility in mind. Sometimes, the best decisions come from revisiting initial choices. Make sure to reflect on your needs as they change.

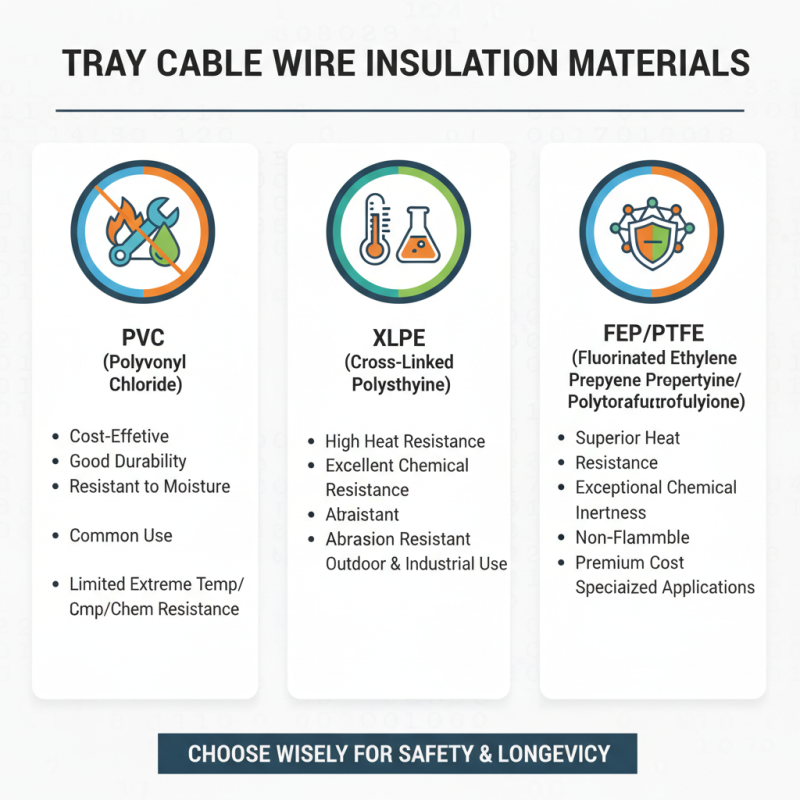

Assessing the Importance of Insulation Materials in Tray Cables

When selecting tray cable wire for your project, insulation materials play a critical role. They ensure the safety and longevity of wiring systems. Different types of insulation provide varied protection against heat, moisture, and chemicals. For example, PVC is widely used due to its cost-effectiveness and decent durability. However, it might not withstand extreme conditions.

Thermoplastic elastomer (TPE) offers better flexibility and resistance. It can endure higher temperatures and has a longer lifespan. Still, it is often pricier. Consider your project environment. Is it an outdoor setting or a high-temperature area? Choosing the right insulation can prevent costly failures.

It's essential to evaluate how often the cable will be moved or flexed. Heavy-duty applications require robust insulation. Over time, wear and tear can impact performance. Think about the potential risks. Can inadequate insulation lead to downtime or hazards? Address these concerns when making your decision. Selecting the right material is vital, yet it requires careful thought and consideration.

Compliance with Safety Standards in Tray Cable Selection

When selecting tray cable wire for your project, compliance with safety standards is paramount. The National Electrical Code (NEC) provides guidelines that help ensure safety and performance. According to industry reports, approximately 30% of electrical fires result from improper wiring. Ignoring safety standards increases risks significantly.

Tips: Always check the wire's ratings. Using wire that meets UL standards can prevent potential hazards. Ensure the cable is suitable for your specific environment—be it indoor or outdoor. Pay attention to the temperature rating too.

In recent studies, proper cable insulation can prevent overheating, which is a common issue in poorly selected wiring. Remember, choosing the right type of tray cable not only supports efficiency but also safeguards personnel and property. The wrong choice might lead to code violations. Cost shouldn't override compliance, as future expenses from accidents can be substantial.

Tips: Don’t rush the decision-making process. Mistakes in selecting tray cable can have long-term consequences. Review performance specifications carefully. They reveal a wire's durability and resistance to environmental factors. A thoughtful approach respects both safety and project integrity.

Related Posts

-

Top 10 Benefits of Using Tray Cable Wire for Reliable Electrical Installations in 2023

-

The Best 10 Tray Cable Wire Types for Your Electrical Projects

-

How to Choose the Right Metal Clad Cable for Your Electrical Needs?

-

Top Electrical Cable Tray Types: Which One is Right for Your Project?

-

7 Reasons Why Shielded Power Cables Enhance Electrical Safety and Efficiency

-

10 Best Micro Coaxial Cables for Unmatched Performance in 2023

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•