A partner you can trust

The Ultimate Guide to Choosing Flexible Cable Conduit for Your Wiring Needs

In today's rapidly evolving electrical landscape, the demand for efficient and reliable wiring solutions has never been more critical. An increasing emphasis on safety, flexibility, and durability has led to the widespread adoption of flexible cable conduit systems across various industries. According to recent market research, the global flexible conduit market is projected to grow significantly, reaching approximately $2 billion by 2025, driven by the expansion of the construction and automotive sectors. This growth highlights the increasing recognition of flexible cable conduit as a vital component in safeguarding electrical wiring against external factors, enhancing both convenience and functionality in installation.

Flexible cable conduit provides superior protection against impacts, moisture, and chemical exposures, making it a preferred choice for diverse applications ranging from residential projects to complex industrial environments. As technology continues to advance, manufacturers are innovating with materials that improve conduit performance while meeting stringent regulatory standards. Understanding the characteristics and benefits of the various types of flexible conduit available on the market is essential for professionals tasked with ensuring electrical safety and efficiency. This guide aims to equip you with the knowledge necessary to make informed decisions when selecting flexible cable conduit for your wiring needs, ensuring optimal performance and reliability in any electrical installation.

Understanding Flexible Cable Conduits: Types and Materials

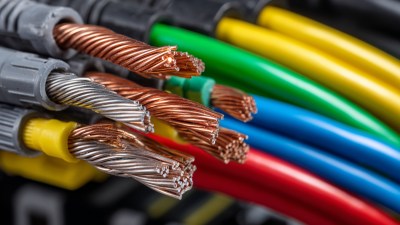

Flexible cable conduits are critical components in wiring systems, offering protection and organization for electrical wires in various environments. When considering the selection of a conduit, it is essential to understand the different types and materials available. One common type is the non-metallic conduit, made from materials such as PVC or nylon, which provides excellent resistance to weathering and chemicals. This makes them suitable for both indoor and outdoor applications, especially in environments where moisture or harsh chemicals may be present.

On the other hand, metallic conduits, such as those made from aluminum or steel, provide enhanced strength and durability. These are often used in industrial settings where wires may require additional protection from physical damage. Metallic conduits can also offer better grounding capabilities, thus reducing electromagnetic interference. Another significant consideration is the flexibility of the conduit itself; some materials are more pliable than others, allowing for easier installation in tight spaces or complex layouts. Understanding these factors is crucial for making informed decisions that align with the specific requirements of your wiring project.

Benefits of Using Flexible Cable Conduit for Wiring Projects

Flexible cable conduits have become increasingly vital in modern wiring projects, offering numerous benefits that enhance both safety and efficiency. According to a report by the National Electrical Manufacturers Association (NEMA), the use of flexible conduits can reduce installation time by up to 30%. This is particularly advantageous in complex environments where access is limited and conventional rigid conduits would be cumbersome. The adaptability of flexible conduits allows for more efficient routing, accommodating a variety of layouts without compromising the integrity of the wiring.

Moreover, flexible cable conduits provide enhanced protection against environmental factors. Research by the International Wiring Standards Organization indicates that systems using flexible conduits exhibit a 40% lower failure rate in harsh conditions compared to traditional setups. This durability is essential for installations in settings exposed to moisture, chemicals, or physical stress. By minimizing the risk of damage, flexible conduits contribute to longer system lifespans and reduced maintenance costs, making them a smart investment for both residential and commercial wiring needs.

Key Factors to Consider When Choosing Flexible Cable Conduit

When selecting flexible cable conduit for your wiring needs, several key factors should be carefully considered to ensure optimal performance and safety. First, the operating environment plays a crucial role. Whether the conduit will be exposed to extreme temperatures, moisture, or chemical exposure determines the material you should choose. For instance, if the conduit is to be used outdoors, a UV-resistant product is essential to prevent degradation over time.

Another important aspect is the conduit’s size and flexibility. The inner diameter must accommodate the cables you intend to use, while the flexibility should match the installation requirements. If you need to navigate tight spaces or complex layouts, a more flexible product will serve you better. Additionally, consider the conduit’s bending radius; this affects how easily you can install it in challenging configurations.

**Tips:** Always measure your cables before selecting a conduit to ensure a proper fit. Additionally, check for any specific standards or regulations applicable in your area, as these can dictate certain requirements for your installation. Lastly, assess the expected lifespan of the conduit material to avoid premature replacements, ultimately saving both time and cost in the long run.

The Ultimate Guide to Choosing Flexible Cable Conduit for Your Wiring Needs

| Feature | Importance | Recommended Options |

|---|---|---|

| Material | High | PVC, Polyethylene |

| Flexibility | High | Highly Flexible Conduit |

| Temperature Rating | Medium | Up to 90°C |

| UV Resistance | Medium | UV Stabilized Types |

| Water Resistance | High | Waterproof Conduits |

| Bend Radius | High | Small Bend Radius Options |

| Size Variability | High | Various Diameter Options |

| Cost | Medium | Budget-Friendly Options |

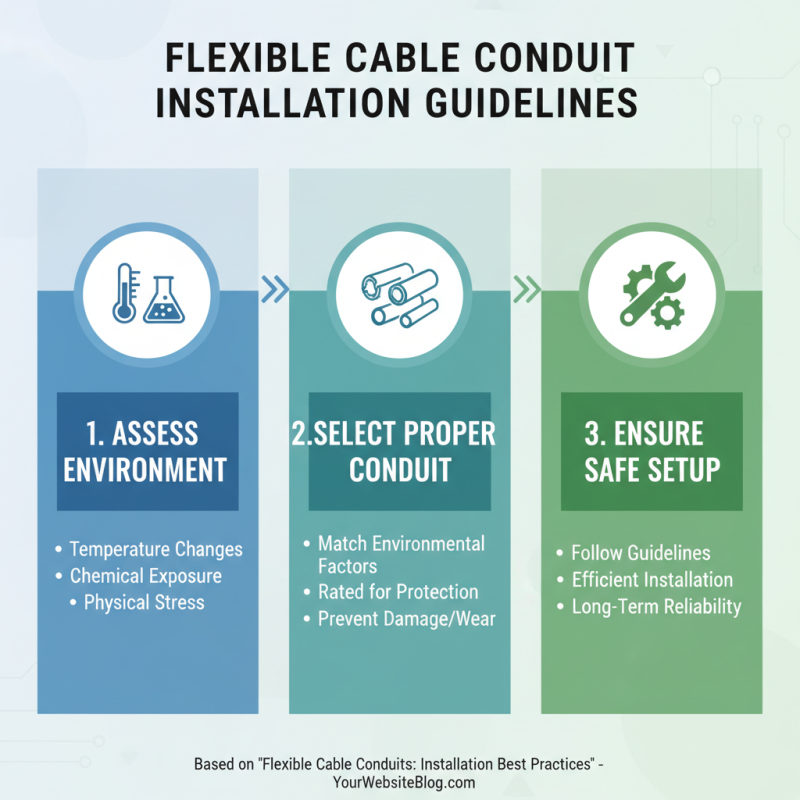

Installation Guidelines for Flexible Cable Conduits

When installing flexible cable conduits, it's essential to follow specific guidelines to ensure a safe and efficient setup. First and foremost, assess the environment where the conduit will be installed. Consider factors such as temperature fluctuations, exposure to chemicals, and physical stress. Properly rated conduits should be selected based on these environmental considerations to prevent any damage or deterioration over time.

Next, prepare the installation area carefully. Clear any debris and ensure that surfaces are clean and dry. Accurate measurement of conduit lengths is crucial, so take your time to mark out the necessary sections. When cutting the conduit, use appropriate tools to avoid any jagged edges, which can compromise the integrity of the installation. It's advisable to support the conduit at intervals specified by regulations or guidelines to prevent sagging. Finally, when running cables through conduits, ensure that the cables are not tightly packed, allowing for adequate air circulation and making future maintenance easier.

Common Applications and Uses of Flexible Cable Conduit in Wiring

Flexible cable conduits are essential in various electrical wiring applications, providing protection and organization for cables in challenging environments. Common uses include industrial settings, automotive applications, and residential wiring. In industrial environments, flexible conduits safeguard electrical wiring from dust, moisture, and mechanical impacts, which are crucial for maintaining operational efficiency. According to industry reports, approximately 40% of electrical failures result from environmental factors that flexible conduits can mitigate.

In automotive applications, flexible cable conduits are vital due to their ability to withstand vibrations and temperature variations. They help protect sensitive wiring from abrasion and exposure to harmful substances. A 2022 survey by the Electrical Association highlighted that nearly 30% of automotive failures are attributed to wiring issues that could be effectively managed with proper conduit usage.

Tips: When selecting flexible cable conduits, it is essential to consider the material's resistance to chemicals and temperatures specific to the intended application. Additionally, ensure the conduit is compatible with the electrical wiring to maintain compliance with safety standards. Understanding these factors can help prevent future electrical issues and extend the lifespan of your wiring systems.

Related Posts

-

Understanding the Benefits of Using Flexible Cable Conduit in Your Projects

-

How to Choose the Right Flexible Cable Conduit for Optimal Electrical Safety

-

How to Choose the Right Armoured Electrical Cable for Your Specific Needs

-

What is the Importance of Wire Cable in Modern Electrical Systems

-

Top Electrical Cable Tray Types: Which One is Right for Your Project?

-

Top 5 Wire Cable Types for Efficient Connectivity and Enhanced Performance

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•