A partner you can trust

Understanding the Impact of Electric Cable Quality on Energy Efficiency and Safety in Modern Infrastructure

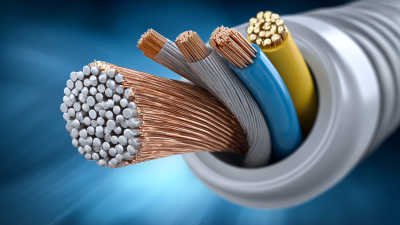

As modern infrastructure evolves, the quality of materials used becomes increasingly critical for ensuring

energy efficiency and safety. Among these materials, electric cables play a pivotal role in supporting the operation of diverse electrical systems, from residential buildings to sprawling industrial complexes. The electric cable's quality directly influences power transmission efficiency, reducing energy losses and enhancing overall performance. Additionally, subpar electric cables pose significant safety risks, including overheating, short circuits, and potential fire hazards.

Understanding the intricate relationship between electric cable quality and its implications for energy efficiency and safety is essential for stakeholders in infrastructure development. This exploration not only underscores the necessity for rigorous standards and testing but also highlights the potential benefits of investing in

high-quality electric cables as we strive towards a more

sustainable and secure energy future.

As modern infrastructure evolves, the quality of materials used becomes increasingly critical for ensuring

energy efficiency and safety. Among these materials, electric cables play a pivotal role in supporting the operation of diverse electrical systems, from residential buildings to sprawling industrial complexes. The electric cable's quality directly influences power transmission efficiency, reducing energy losses and enhancing overall performance. Additionally, subpar electric cables pose significant safety risks, including overheating, short circuits, and potential fire hazards.

Understanding the intricate relationship between electric cable quality and its implications for energy efficiency and safety is essential for stakeholders in infrastructure development. This exploration not only underscores the necessity for rigorous standards and testing but also highlights the potential benefits of investing in

high-quality electric cables as we strive towards a more

sustainable and secure energy future.

Assessing the Role of Electric Cable Materials in Energy Loss Reduction

When it comes to modern infrastructure, the quality of electric cables plays a pivotal role in minimizing energy loss. According to the International Energy Agency (IEA), approximately 8-10% of electricity is lost during transmission due to inefficiencies in cable materials and installation practices. Higher quality materials, such as copper and aluminum, exhibit lower resistivity, allowing electricity to flow more efficiently and reducing energy waste. This is particularly critical in urban environments where energy demands are high, and reliable infrastructure is essential.

Tip: When selecting electric cables, consider investing in high-conductivity materials. Although initial costs may be higher, the long-term savings from reduced energy loss can offset these expenses significantly.

Additionally, the use of insulating materials can further enhance energy efficiency. A report by the National Renewable Energy Laboratory (NREL) indicates that using cables with superior insulation can lead to an up to 5% decrease in energy loss. It’s important for electrical engineers and designers to prioritize materials that not only adhere to safety standards but also contribute to a greener, more energy-efficient infrastructure.

Tip: Always verify the specifications and ratings of electric cables to ensure they meet the required energy efficiency standards for your projects. This diligence can improve safety and performance while promoting sustainability.

Identifying Key Features of High-Quality Electric Cables for Safety

When it comes to modern infrastructure, the quality of electric cables plays a crucial role in ensuring energy efficiency and safety. High-quality electric cables are characterized by several key features that not only enhance performance but also mitigate risks associated with electrical failures. One of the primary attributes is the material used in the cable. According to the International Electrotechnical Commission (IEC), copper remains the preferred choice for wiring due to its superior conductivity rates, allowing for lower energy losses, which can be up to 10% reductions in overall energy consumption compared to lower-grade alternatives.

Moreover, cable insulation is critical for safety, as it prevents current leakage and reduces the chances of electrical fires. The National Fire Protection Association (NFPA) reports that faulty electrical wiring is responsible for approximately 67% of home electrical fires. High-quality cables typically utilize advanced insulation materials such as cross-linked polyethylene (XLPE), which not only withstands higher temperatures but also has better resistance to environmental stressors. With cables designed to meet or exceed industry standards such as UL 44 and IEC 60228, infrastructure providers can confidently invest in systems that promote safety while enhancing energy efficiency, fulfilling both regulations and consumer expectations.

Understanding the Impact of Electric Cable Quality on Energy Efficiency and Safety in Modern Infrastructure

| Cable Type | Conductor Material | Insulation Type | Voltage Rating | Temperature Rating | Energy Efficiency Rating | Safety Compliance Standards |

|---|---|---|---|---|---|---|

| H05VV-F | Copper | PVC | 300/500V | 70°C | Class A | IEC 60227 |

| H07RN-F | Copper | Rubber | 450/750V | 90°C | Class B | EN 50525-2-21 |

| NYM | Copper | PVC | 300/500V | 70°C | Class A | VDE 0100 |

| SWA | Aluminium | XLPE | 600/1000V | 90°C | Class A | BS 5467 |

Analyzing the Relationship Between Cable Specifications and Energy Efficiency

The quality of electric cables plays a crucial role in determining energy efficiency within modern infrastructure. Higher-grade cables, designed to meet specific electrical specifications, often exhibit lower resistance and reduced energy losses during transmission.

For instance, cables made from premium materials like copper not only have a better conductivity but also ensure a more consistent energy flow. This directly translates to improved energy efficiency, as less energy is wasted as heat, allowing for more effective utilization of power generated.

Moreover, the relationship between cable specifications and energy efficiency extends to safety concerns. Cables that adhere to stringent industry standards are less likely to overheat, thereby minimizing the risk of electrical failures or fires. The insulation quality, gauge size, and voltage rating of a cable all contribute to its overall safety profile.

When infrastructure projects prioritize high-quality specifications, they not only enhance energy efficiency but also fortify safety measures, creating a more reliable electrical framework in urban environments. The significance of selecting the right cables cannot be overstated, as doing so paves the way for sustainable energy practices and the longevity of electrical systems.

Implementing Best Practices for Cable Installation in Modern Infrastructure

In modern infrastructure, ensuring optimal energy efficiency and safety begins with the implementation of best practices for cable installation. Recent studies indicate that up to 30% of energy loss in electrical systems can be attributed to poor cable quality and installation practices. Therefore, adhering to stringent quality standards and utilizing high-grade materials during the installation phase is critical. Regular assessments, such as using advanced network cable testers, can substantially improve the integrity of the electrical installations, identifying potential issues before they escalate into costly failures.

Moreover, the integration of audio and video over Internet Protocol (AV over IP) systems necessitates specialized installation techniques. As data transmission over networks continues to grow, with submarine cables handling more than 99% of global intercontinental communication, the focus on secure and efficient cable installation becomes paramount. Industry reports suggest that the demand for robust undersea infrastructure is on the rise, reinforcing the need for meticulous planning and execution in cable installation. These best practices not only enhance performance but also safeguard critical communications infrastructure from potential vulnerabilities, ensuring both energy efficiency and safety across modern networks.

Evaluating Regulatory Standards for Electric Cable Quality in Energy Projects

Regulatory standards for electric cable quality play a crucial role in ensuring the safety and efficiency of energy projects. As infrastructure demands increase alongside technological advancements, the importance of standardized testing and quality assurance cannot be overstated. These regulations help establish minimum performance criteria for electric cables, dictating factors such as conductivity, insulation resistance, and thermal performance. By adhering to these standards, project managers can mitigate risks associated with electrical failures, which can lead to costly downtimes and safety hazards.

Moreover, evaluating these regulatory benchmarks allows stakeholders to align their practices with national and international safety protocols. This evaluation not only fosters transparency and accountability within the industry but also encourages innovation in cable manufacturing. Ultimately, a robust regulatory framework ensures that electric cables contribute positively to energy efficiency, supporting sustainable infrastructure development. By prioritizing cable quality through effective regulations, we can enhance the reliability of energy systems while safeguarding public safety.

Related Posts

-

Advantages of Choosing High Quality Electric Cable for Your Projects

-

10 Essential Tips for Sourcing Electric Cables Effectively in 2023

-

Innovative Uses of Electric Cable Wire in Modern Technology

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

-

How to Choose the Right Armoured Electrical Cable for Your Specific Needs

-

Why Lead Sheathed Cable is Essential for Modern Electrical Applications

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•