A partner you can trust

What is Metal Clad Cable and How is it Used?

Metal clad cable is essential in various industries. It offers durability and protection for electrical conductors. According to industry expert John Reed, “Metal clad cable enhances safety and efficiency.” His insights highlight its importance in modern applications.

This type of cable features a metal sheath. This design protects against moisture and physical damage. It is often used in commercial buildings and industrial settings. The robust nature of metal clad cable reduces the risk of electrical hazards. However, some users have encountered installation challenges. Proper training is vital to avoid mistakes and ensure safety.

In recent years, the demand for metal clad cable has increased. As technology advances, so do cable requirements. Companies must adapt to new standards and specifications. This evolution prompts a continual reassessment of installation practices. Understanding metal clad cable's role is crucial for industry professionals.

Definition and Composition of Metal Clad Cable

Metal clad cable is a type of electrical cable designed for enhanced durability and protection. It consists of conductors encased in metal. This outer layer usually consists of aluminum or steel. This metal shielding provides a barrier against physical damage, moisture, and corrosive environments.

The composition of metal clad cable varies. Inside, it may have one or more insulated conductors. These conductors can be made from copper or aluminum. The choice of materials influences both performance and cost. The cable also has a protective jacket that further secures the internal components. This construction makes it a popular choice for industrial applications.

When using metal clad cable, installation conditions matter. It's not ideal for all environments. For instance, bends or tight spaces can weaken the cable. This can lead to potential failures over time. It’s essential to evaluate locations carefully. Proper planning can help maintain the integrity of the installation.

Metal Clad Cable Usage in Various Industries

The chart above illustrates the percentage of metal clad cable usage across various industries, highlighting its significance in construction, manufacturing, telecommunications, energy, and transportation sectors.

Types of Metal Clad Cable and Their Applications

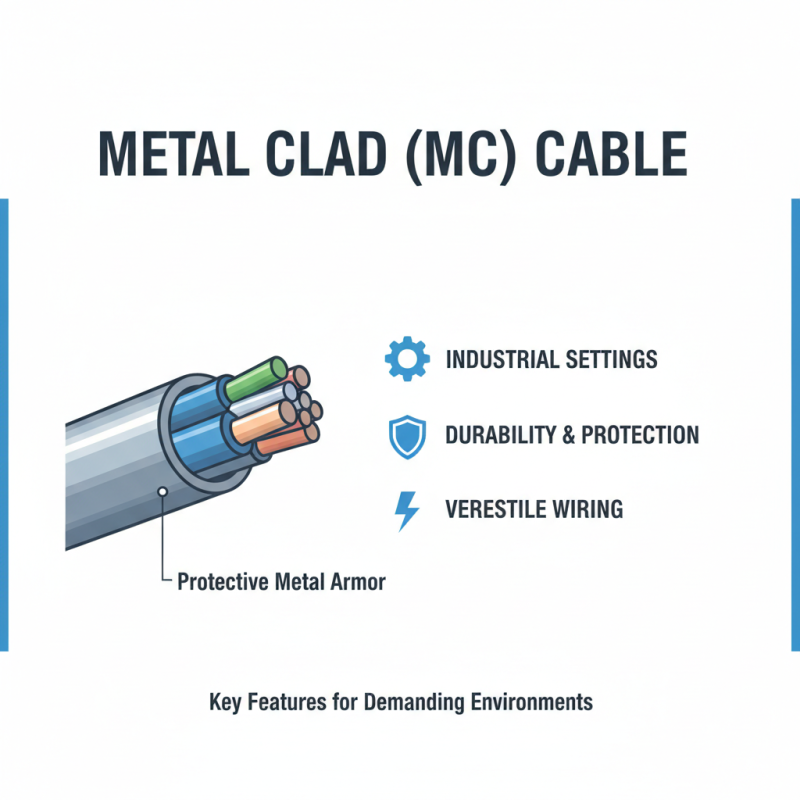

Metal clad cable (MC cable) is a versatile type of electrical wiring. It features a metal armor that provides excellent protection. This makes it suitable for various environments. It's often used in industrial settings due to its durability.

There are several types of metal clad cables. One common type is the MC-HL cable. This type is suitable for harsh conditions, like those found in commercial kitchens. It can withstand moisture and temperature variations. Another type is the MC-O cable. This type is designed for outdoor use, offering extra resistance to outdoor elements.

Applications of metal clad cables are diverse. They are used in commercial buildings, residential areas, and even in marine settings. However, some users overlook installation guidelines. Ensuring proper installation is critical to avoid safety hazards. Users should always consider local codes and regulations when working with MC cables.

Advantages of Using Metal Clad Cable in Electrical Installations

Metal clad cable (MC cable) is a popular choice for various electrical installations. Its construction includes an inner insulated conductor surrounded by metal shielding. This design offers a range of advantages that make it suitable for both residential and commercial use. One of the key benefits is its durability. The metal outer layer protects against impact and moisture, reducing the risk of damage. This makes MC cable ideal for harsh environments and outdoor applications.

Another advantage is its efficient grounding feature. The metal sheath acts as a ground path, ensuring safety and compliance with electrical codes. In addition, MC cables are often easier to handle during installation due to their flexibility. They can be run without conduit in many cases, saving time and material costs. However, some installers may struggle with proper bending techniques or securing the cable correctly, leading to potential imperfections in the setup.

Cost is an essential factor. While MC cables might appear more expensive upfront, their longevity and reduced maintenance needs can lead to savings in the long run. Some electricians might overlook the installation complexity, resulting in avoidable errors. This raises an important consideration: taking time to plan and execute installations carefully is crucial for maximizing the benefits of metal clad cable.

Installation Methods and Best Practices for Metal Clad Cable

When installing Metal Clad Cable (MC cable), proper methods are crucial for safety and efficiency. MC cable features an outer metal sheath that provides durability, making it suitable for various settings. Its construction allows for enhanced protection against physical damage. According to the National Electrical Code (NEC), any installation must comply with strict guidelines to ensure reliability.

Best practices emphasize securing the cable properly to prevent movement. It is essential to use appropriately sized fittings to maintain the integrity of the cable. Additionally, while some installers prefer to run MC cable in exposed areas, understanding local regulations is vital. Not every location allows for this practice. Reports indicate that improper installation can lead to significant safety hazards.

Cable bending is another important consideration. MC cable must not be excessively bent, as this can stress the insulation. Research shows that bending beyond recommended limits affects performance. Regular inspections can help detect wear early, but many installers overlook this step. Neglecting it can result in costly repairs down the line. Each installation process should reflect careful planning and attention to detail, ensuring that safety standards are met throughout.

Safety Considerations and Compliance Standards for Metal Clad Cable

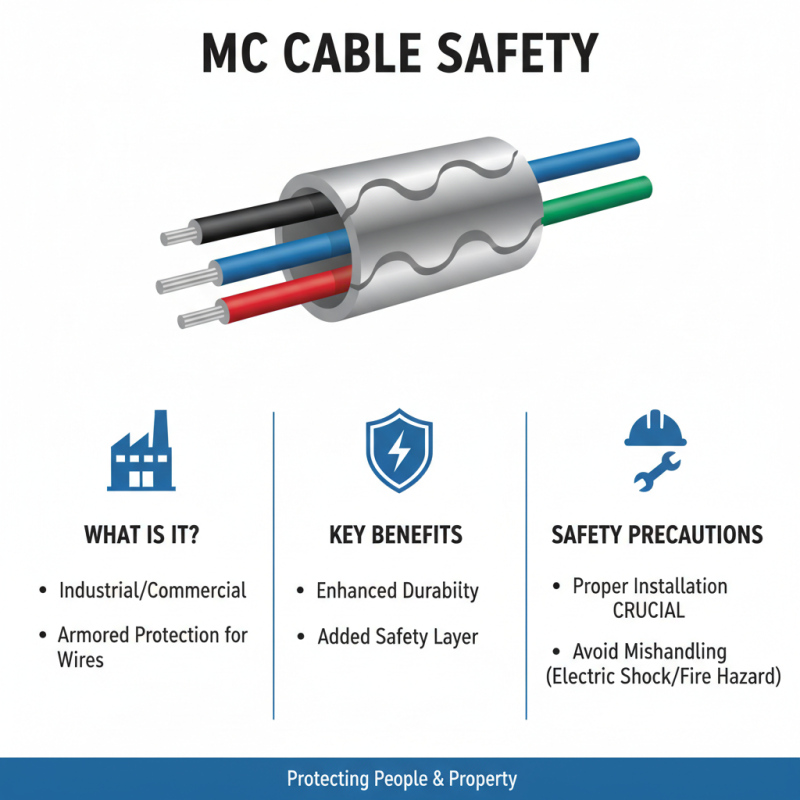

Metal clad (MC) cable is commonly used in industrial and commercial settings. Its design provides an added layer of protection for electrical conductors. However, safety considerations are crucial when dealing with MC cable. Proper installation is vital. Mishandling can lead to serious hazards.

Compliance with local codes is mandatory. Regulations ensure that installations meet safety standards. Failure to comply can have serious consequences. Regular inspections are also necessary. They help identify potential issues before they become dangerous.

Understanding grounding requirements is essential. It prevents electrical faults and improves safety. Workers need proper training. They must be educated on potential hazards. Awareness can reduce accidents. As technology evolves, staying updated on new safety practices is key. Ignoring this can lead to complacency, posing risks to both personnel and property.

Related Posts

-

How to Choose the Right Electric Cable for Your Global Procurement Needs

-

Understanding the Benefits of Metal Clad Cable for Modern Electrical Installations

-

Exploring the Benefits of Shielded Power Cable for Enhanced Electrical Performance

-

Comprehensive Guide to Selecting the Best Flexible Cable Conduit for Your Project

-

How to Choose the Best Multi Cable Charger for Your Devices: Key Features and Expert Insights

-

Essential Tips for Choosing the Right Cooker Cable for Your Kitchen Needs

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•