A partner you can trust

Essential Tips for Choosing the Right Shore Power Cable for Your Needs

Choosing the right shore power cable is crucial for ensuring the safety and reliability of your marine power needs. As industry expert John Smith, a leading marine electrical engineer, emphasizes, “A shore power cable is not just a simple tool; it is a lifeline for your vessel’s electrical system.” This statement highlights the importance of selecting the appropriate cable that meets both performance and safety standards.

With the increasing reliance on electrical systems in modern boats and yachts, understanding the specifications and functionality of shore power cables has never been more essential. Factors such as cable length, gauge, and insulation type can significantly impact the efficiency and safety of power transfer from shore to vessel. Whether you're a seasoned mariner or a novice boat owner, navigating the various options available can be daunting.

In this article, we will explore essential tips and considerations that can guide you in making an informed choice when selecting a shore power cable. Ensuring you have the right equipment will not only enhance your boating experience but also protect your investment and ensure compliance with safety regulations.

Understanding Shore Power Cables: The Basics and Importance

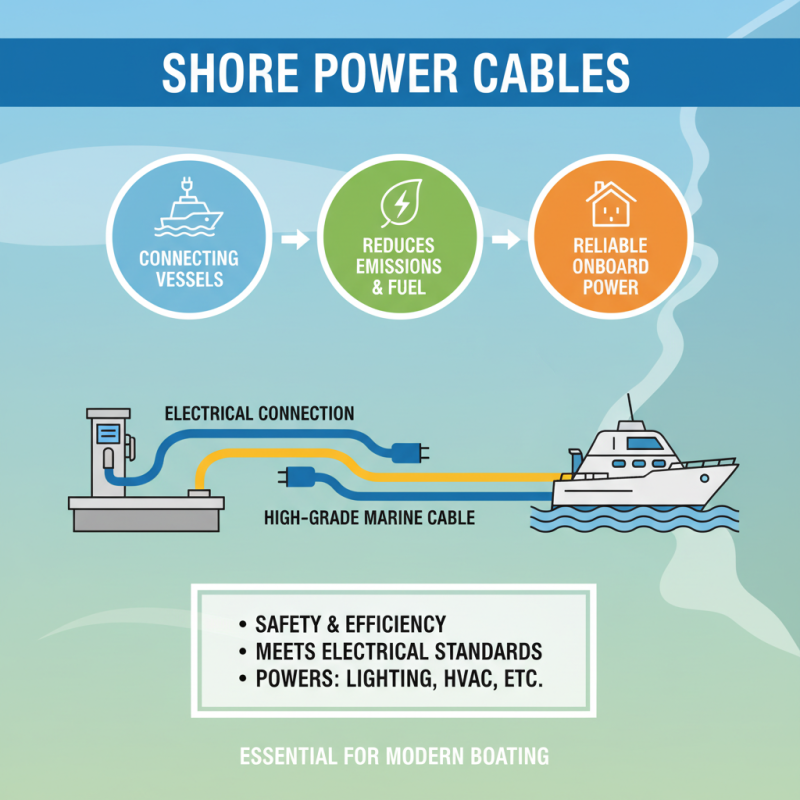

Shore power cables are essential for connecting vessels to onshore electrical power sources, allowing boats to operate electrical systems without relying on their onboard generators. Understanding the basics of shore power cables is crucial for any boat owner or operator, as these cables ensure safety, efficiency, and compliance with electrical standards. At their core, shore power cables serve to minimize fuel consumption and reduce emissions while providing a reliable power source for various onboard systems, such as lighting, heating, and air conditioning, when docked.

When selecting the right shore power cable, it’s important to recognize the significance of cable specifications, such as gauge, insulation type, and length. The gauge determines the amount of current the cable can safely carry, so choosing a cable with an appropriate thickness for your vessel’s power needs is critical. Additionally, the insulation materials should be rated for marine environments, providing protection against moisture and corrosion. Since the length of the cable can impact voltage drop, it is advisable to select a cable that adequately covers the distance between your vessel and the shore power connection, ensuring optimal performance and safety.

Key Factors to Consider When Selecting Shore Power Cables

When selecting shore power cables, several key factors must be taken into consideration to ensure safety and efficiency. First and foremost, it’s essential to determine the correct cable length. A cable that is too short will limit your maneuverability, while an excessively long cable can lead to voltage drops, which may negatively affect the performance of your onboard systems. Additionally, understanding the power requirements of your vessel is crucial; you should know the total amperage and wattage needed, as shore power cables are rated for specific power levels.

Another vital factor is the cable insulation and construction material. Look for cables that are durable and resistant to environmental factors such as saltwater, UV exposure, and physical abrasion. The gauge of the wire used in the cable also plays a significant role in its performance and safety; a thicker gauge can handle higher loads and reduce the risk of overheating. Lastly, consider any applicable safety standards and regulations to ensure that your chosen shore power cable complies with the necessary guidelines, thus guaranteeing optimal operation during your maritime activities.

Essential Tips for Choosing the Right Shore Power Cable for Your Needs

| Factor | Description | Importance |

|---|---|---|

| Cable Length | Determine the distance between the shore supply and the vessel to find the appropriate cable length. | High |

| Ampacity | Assess the current carrying capacity required for your equipment to choose a cable that can handle it safely. | Critical |

| Voltage Rating | Select a cable with a voltage rating that matches your power supply to ensure compatibility. | High |

| Cable Type | Choose between fixed or flexible cables based on your application and installation preferences. | Medium |

| Environmental Ratings | Ensure the cable is rated for marine environments to resist saltwater, UV radiation, and other harsh conditions. | High |

| Connector Type | Verify that the connectors match those used on your vessel and shore power supply. | Critical |

| Compliance Standards | Check for compliance with relevant safety and quality standards for marine cables. | High |

Matching Cable Ratings to Your Power Requirements

When selecting a shore power cable, it is crucial to match the cable ratings with your specific power requirements to ensure safety and efficiency. According to the National Fire Protection Association (NFPA) standards, the appropriate cable should not only support the required voltage but also have sufficient amperage ratings. For marine applications, the typical shore power system operates at 120V or 240V with current ratings often ranging from 15A to 100A. Selecting a cable that meets or exceeds these specifications can help prevent overheating and potential fire hazards.

Additionally, it’s important to consider the gauge of the wire in the cable, as this directly influences power transmission and voltage drop. The American Boat and Yacht Council (ABYC) recommends using thicker cables for longer runs to minimize voltage drops, which should be kept below 3% for optimal performance. For instance, if you are using a 50A service at a distance of 100 feet, utilizing a 6 AWG cable instead of 8 AWG can significantly improve efficiency. Proper cable matching, therefore, enhances both the safety and functionality of shore power connections, ensuring that vessels operate smoothly while docked.

Safety Features and Standards for Shore Power Cables

When selecting a shore power cable, one of the most critical considerations is ensuring that it adheres to safety features and standards. Shore power cables are designed to connect boats to an external power supply, making it essential that they are built to withstand various environmental conditions without compromising safety. Key safety features include adequate insulation, robust connectors, and over-current protection, all of which play a vital role in preventing electrical shorts and overheating.

Moreover, compliance with relevant safety standards is paramount. Different regions may have specific regulations guiding the use and manufacture of shore power cables, often established by recognized organizations to ensure user safety. These standards dictate aspects such as cable thickness, material composition, and testing procedures, ensuring that any cable in use is not only durable but also capable of handling the power demands of marine equipment. Familiarizing oneself with these standards can help in selecting a cable that not only fits your needs but also enhances safety while you enjoy your time on the water.

Power Consumption Comparison of Shore Power Cables

Maintenance Tips for Prolonging the Life of Shore Power Cables

Maintaining shore power cables is crucial for ensuring their longevity and enhancing efficiency during use. According to a report by the International Council on Clean Transportation (ICCT), maintaining electrical infrastructure can increase equipment lifespan by up to 30%. Regular inspections are essential; visual checks for external damage or corrosion can help identify potential issues before they escalate. Furthermore, ensuring connections remain clean and free from moisture will reduce the likelihood of electrical faults, which can lead to costly repairs and downtime.

Another important maintenance tip involves proper storage when cables are not in use. The National Marine Electronics Association (NMEA) recommends coiling cables loosely to avoid kinks and stress points, which can lead to internal wire damage. Additionally, storing cables in a cool, dry environment helps prevent deterioration from UV exposure and moisture. Following these guidelines is not only vital for the performance of the cables but also essential for safety, as damaged cables can pose significant risks in marine environments. By incorporating these maintenance practices, users can ensure their shore power cables continue to function effectively for years to come.

Related Posts

-

How to Effectively Utilize Shore Power Cables for Sustainable Energy Solutions

-

10 Best Marine Battery Cables for Reliable Performance in 2023

-

2025 Top Cooker Cable Innovations: Enhance Your Cooking Experience

-

Top Electric Wire and Cable Innovations to Watch in 2025

-

Why Lead Sheathed Cable is Essential for Modern Electrical Applications

-

2025 How to Choose the Best Underground Cable Conduit for Your Project

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•