A partner you can trust

2026 Top Electrical Cable Connectors You Need to Know?

In the realm of electrical engineering, understanding electrical cable connectors is essential. As industry expert Dr. Sarah Thompson notes, "The right connector can enhance performance and longevity." This emphasizes the importance of choosing the right components for any electrical project.

The landscape of electrical cable connectors is evolving rapidly. New materials and designs emerge each year, aiming to improve efficiency and safety. However, with so many options available, it’s easy to feel overwhelmed. Identifying the best choices requires careful consideration and knowledge of current trends.

In 2026, various electrical cable connectors will dominate the market. There will be innovations that challenge traditional designs. It's crucial to stay informed and reflect on what works best for your needs. Ultimately, the right connector can make all the difference in any electrical system's performance.

Overview of Electrical Cable Connectors in 2026

As we explore electrical cable connectors in 2026, it's essential to recognize their evolving role in technology. According to recent data from industry reports, the global market for cable connectors is projected to grow at a CAGR of 6.5% through the next decade. This growth is driven by advancements in automation and the increasing demand for reliable connectivity in various sectors.

The design and functionality of connectors are becoming more critical. With harsh environments in industrial settings, connectors must withstand temperature fluctuations and moisture. Reports indicate that up to 30% of connector failures are linked to environmental factors, emphasizing the need for robust solutions. The industry has seen a surge in innovations like push-pull connectors, which maximize ease of use while ensuring a secure connection.

While there’s significant progress, challenges remain. Not every connector meets stringent quality requirements. Inadequate testing can lead to failures, disrupting projects and increasing costs. Approximately 20% of electrical issues in installations arise from poor connector choices. These statistics highlight the need for careful selection and evaluation in sourcing connectors for projects in 2026.

Overview of Electrical Cable Connectors in 2026

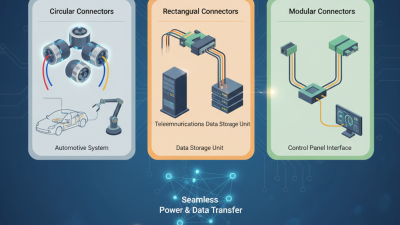

Types of Electrical Cable Connectors You Should Consider

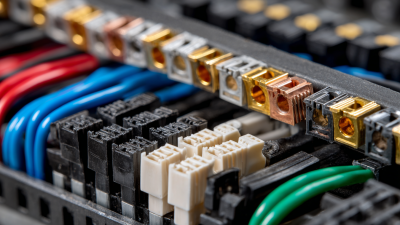

When choosing electrical cable connectors, understanding the different types on the market is crucial. There are several categories, including terminal block connectors, PCB connectors, and circular connectors. Each type offers unique advantages and applications, tailoring to specific project needs. For instance, terminal block connectors are common for connecting multiple wires to a single point, while circular connectors provide rugged connections in outdoor settings.

In a recent industry report, the global demand for electrical connectors is expected to reach $96.5 billion by 2025, driven by technological advancements and growing industries. This trend highlights the importance of selecting the right connector for your application, as improper choices can lead to connection failures or even safety hazards.

Tip: Always consider the operating environment when selecting connectors. Factors like moisture, temperature, and mechanical stress can affect performance.

Another consideration is the ease of installation. Some connectors require specialized tools, which can increase project costs. It's wise to familiarize yourself with the installation requirements of various connectors. This knowledge can prevent delays and additional expenses down the line.

Tip: Regularly review your connector choices. New technologies may offer improved efficiency or safety that could benefit your projects.

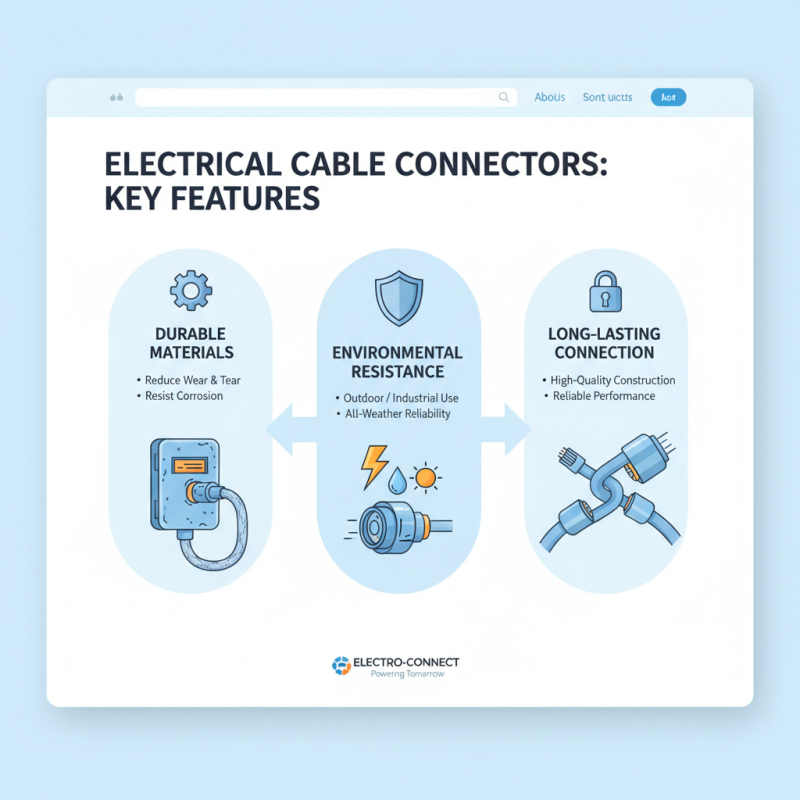

Key Features to Look for in Electrical Cable Connectors

When selecting electrical cable connectors, certain key features stand out. First, look for materials that ensure durability. High-quality connectors reduce wear and tear over time. They should resist corrosion and withstand various environmental conditions. This durability is essential in applications like outdoor or industrial settings.

Another critical aspect is compatibility. Ensure the connectors match the cable specifications precisely. Mismatched sizes can lead to poor connections and failures. Pay attention to the amperage ratings as well. This ensures they can handle the required electrical load without overheating. Small issues can lead to significant problems later on.

Ease of installation is often overlooked. Some connectors offer user-friendly features, like color coding or simple locking mechanisms. These can save time and reduce errors during installation. Not every connector has this benefit, so consider this carefully. It can make a noticeable difference, especially in complex setups.

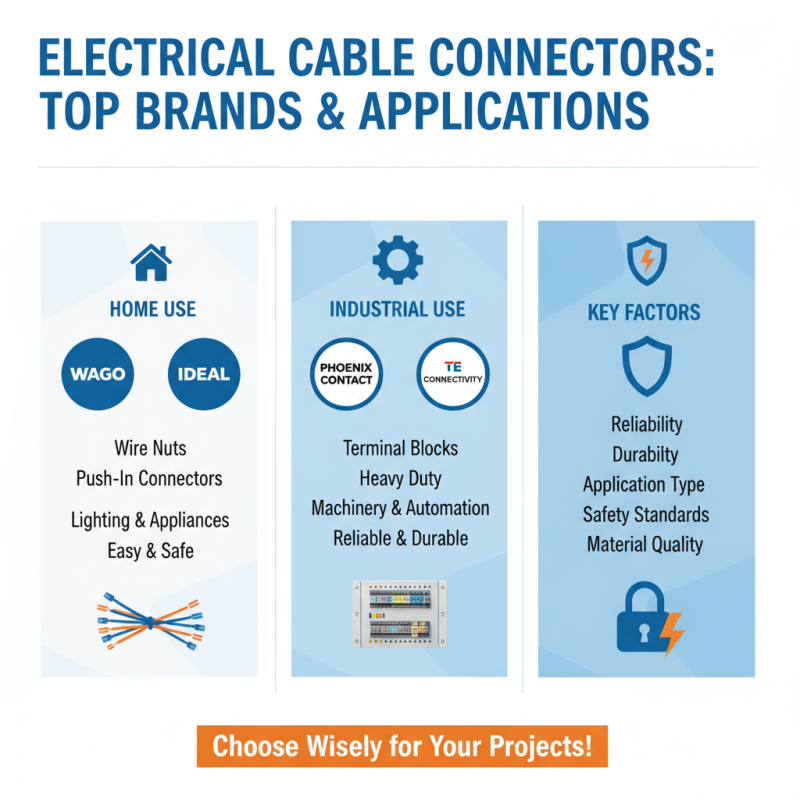

Top Brands and Manufacturers of Electrical Cable Connectors

When it comes to electrical cable connectors, understanding the top brands can make all the difference. Many manufacturers offer various types of connectors, each designed for specific applications. Some connectors are ideal for home use, while others excel in industrial settings. The choice depends on the reliability and durability required for your projects.

Look for reputable brands that emphasize quality control and innovative design. They should provide various connector types, such as waterproof, heat-resistant, or high-current connectors. These features ensure that the connectors can handle different environmental challenges. It's fascinating how small details, like material choice and manufacturing processes, can impact performance significantly.

However, not every well-known brand guarantees excellence. Some connectors may have hidden flaws. Users often face compatibility issues or inadequate customer support. It's essential to review user feedback and engage with professionals when making decisions. A connector that works well in one scenario may fail in another. Aim to balance quality, usability, and cost-effectiveness when selecting your electrical cable connectors.

Applications and Use Cases for Electrical Cable Connectors in 2026

Electrical cable connectors are critical in various applications. In 2026, their importance will only grow. These connectors are essential in industries like renewable energy, automotive, and telecommunications. Each sector utilizes specific connectors to enhance efficiency and safety.

In renewable energy, connectors link solar panels and inverters. The right connector reduces energy loss. Automakers rely on connectors for charging stations and battery systems. They must be durable to withstand harsh conditions. The telecommunications sector needs connectors for fast data transmission. Proper installation is crucial for optimal performance.

Tips: Always ensure connectors are rated for their specific application. Regular maintenance can prevent failures. Don't overlook the environmental factors that may affect your connectors. Proper sealing protects against moisture damage. Understanding these details can enhance performance and safety in your projects.

2026 Top Electrical Cable Connectors You Need to Know

| Connector Type | Application Area | Use Case | Key Features |

|---|---|---|---|

| Circular Connectors | Aerospace | Aircraft communication lines | Durability, lightweight, and high-performance |

| RJ45 Connectors | Networking | Ethernet connections for data centers | High speed, reliable data transmission |

| USB-C Connectors | Consumer Electronics | Charging and data transfer for mobile devices | Reversible design, fast charging capabilities |

| Terminals | Automotive | Battery and power connections in vehicles | Vibration-resistant, high-current capacity |

| D-sub Connectors | Industrial Automation | Signal and power connections in machinery | Versatile, robust, and secure connections |

Related Posts

-

Understanding the Different Types of Electrical Cable Connectors for Your Projects

-

Types of Electrical Cable Connectors What to Know?

-

What Are the Different Types of Electrical Cable Connectors and Their Uses?

-

Understanding the Benefits of Using Flexible Cable Conduit in Your Projects

-

How to Effectively Utilize Shore Power Cables for Sustainable Energy Solutions

-

10 Best Marine Battery Cables for Reliable Performance in 2023

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•