A partner you can trust

Top Electrical Cable Tray Types: Which One is Right for Your Project?

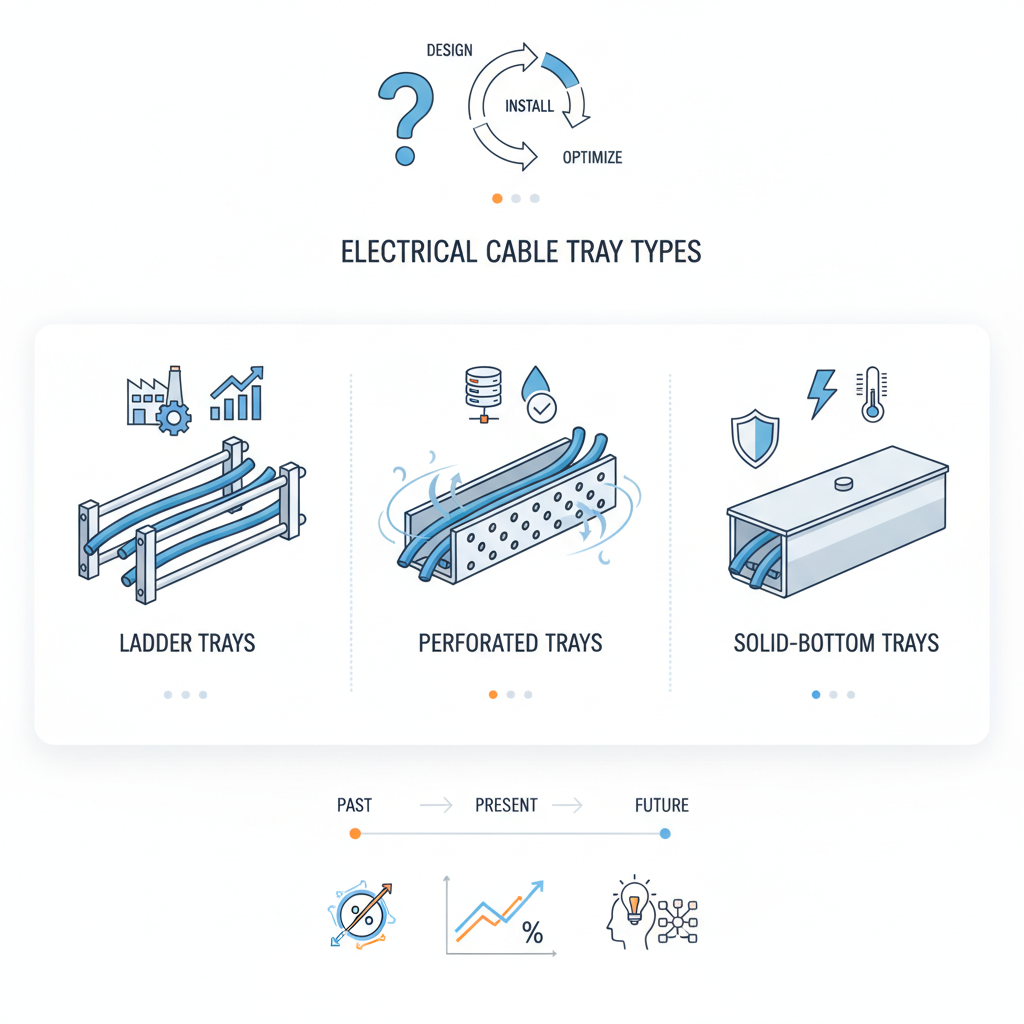

When it comes to designing and implementing electrical systems, choosing the right type of electrical cable tray is crucial for both efficiency and safety. With a variety of cable tray types such as ladder trays, perforated trays, and solid-bottom trays available, understanding their specific applications can significantly impact project outcomes. According to a recent report by the National Electrical Contractors Association (NECA), the cable tray market is projected to grow by 6% annually, emphasizing the increasing reliance on these systems across various industries.

Furthermore, industry expert Dr. Emily Hartman states, “The selection of an appropriate electrical cable tray can streamline installation processes and enhance the longevity of electrical infrastructure.” This highlights the necessity for project managers and engineers to evaluate their options carefully, taking into account factors such as load capacity, environmental conditions, and regulatory compliance. As electrical systems become more complex, so does the requirement for innovative cable management solutions, making it imperative to understand which electrical cable tray type aligns best with specific project needs.

Understanding Electrical Cable Tray Basics for Your Project

When embarking on an electrical installation project, understanding the basics of cable trays is crucial. Cable trays not only provide support and organization for electrical cables but also play a significant role in ensuring safety and compliance with industry standards. According to a recent report by Grand View Research, the global cable tray market is expected to reach USD 12.6 billion by 2025, indicating a growing recognition of their importance in infrastructure.

When selecting a cable tray, it's essential to consider the type that best meets your project's needs. Options commonly include ladder trays, perforated trays, and solid bottom trays. Ladder trays are ideal for large cables as they promote airflow and reduce heat accumulation, while solid bottom trays provide more protection against the environment and physical damage. Understanding the specific requirements of your installation will guide you to the right choice, ensuring efficiency and longevity.

**Tips:** Always check local electrical code requirements before installation, as they can dictate the type of cable trays permissible in your area. Additionally, consider future expansions—selecting a versatile tray can save you time and resources if your cable requirements change. Lastly, ensure proper installation to maximize the effectiveness of your cable management system.

Types of Electrical Cable Trays: An Overview of Options Available

When it comes to selecting the right electrical cable tray for your project, there are multiple options available that cater to various needs and specifications. The U.S. cable tray market, which is projected to grow steadily, highlights the significance of materials such as steel, aluminum, and stainless steel. Each material offers distinct advantages: steel is known for its strength and durability, aluminum is lighter and resistant to corrosion, while stainless steel combines both strength and resistance to harsh environments.

Different types of cable trays, including ladder trays—both swaged and welded—merit careful consideration depending on the specific requirements of your project. Ladder trays are particularly favored for their ability to support heavy cabling loads and facilitate airflow, thus preventing overheating. Meanwhile, the introduction of innovative systems like integrated coupling options reflects ongoing advancements in the industry, improving installation efficiency and safety standards. As these products continue to evolve, understanding the nuanced differences in tray types and materials is crucial for ensuring optimal performance in electrical installations.

Top Electrical Cable Tray Types Distribution

Factors to Consider When Choosing a Cable Tray for Your Needs

When selecting the right cable tray for your project, several key factors should be carefully considered. First, assess the specific requirements of your electrical installation, including the type of cables being used and their intended load capacities. Different cable trays, such as ladder trays, perforated trays, and solid bottom trays, cater to varying environments and cable management needs. For instance, ladder trays offer excellent airflow, making them suitable for high-heat applications, while solid bottom trays provide additional protection for sensitive cables.

Another crucial factor is the material of the cable tray. Options typically include steel, aluminum, and fiberglass, each offering distinct advantages in terms of durability, corrosion resistance, and weight. The choice of material can significantly influence the longevity and maintenance needs of the installation. Additionally, consider the installation environment—whether it’s indoors, outdoors, or in challenging conditions—since this will dictate not only the tray selection but also necessary accessories such as connectors and supports. By evaluating these factors thoroughly, you can ensure that the cable tray system you choose aligns with your project’s requirements and enhances organizational efficiency.

Top Electrical Cable Tray Types: Which One is Right for Your Project?

| Tray Type | Material | Load Capacity | Applications | Installation Cost |

|---|---|---|---|---|

| Ladder Tray | Steel, Aluminum | Up to 600 lbs | Industrial, Commercial | $5-$10 per ft |

| Solid Bottom Tray | Steel, Fiberglass | Up to 500 lbs | Data Centers, Power Plants | $6-$12 per ft |

| Wire Mesh Tray | Steel (Galvanized) | Up to 300 lbs | Low Voltage, Light Duty | $4-$8 per ft |

| Channel Tray | Steel | Up to 400 lbs | HVAC, Plumbing | $5-$10 per ft |

| Perforated Tray | Steel, Aluminum | Up to 250 lbs | Light Duty, Drag Chain | $3-$7 per ft |

Advantages and Disadvantages of Common Cable Tray Types

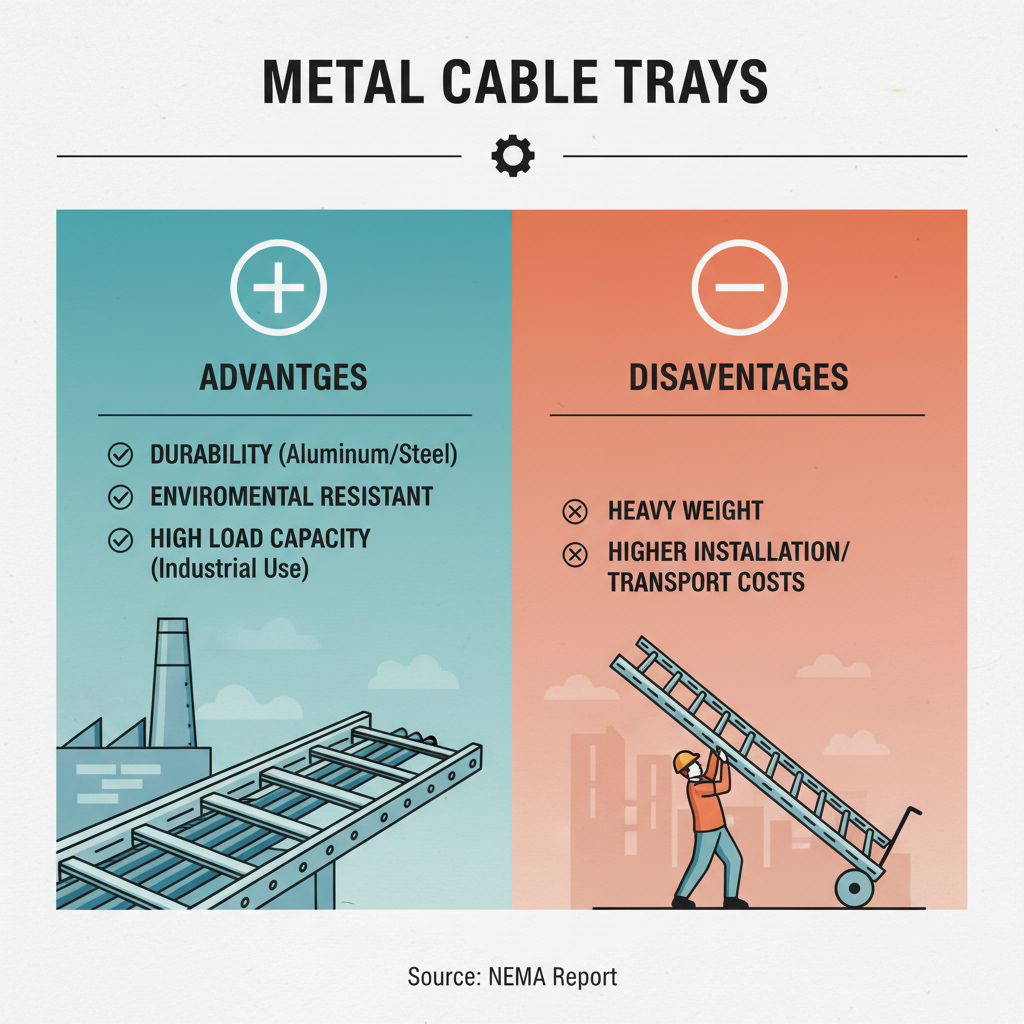

When selecting the appropriate electrical cable tray for your project, understanding the advantages and disadvantages of different types is crucial. For instance, metal cable trays, typically made from aluminum or steel, are highly durable and resistant to damage from environmental factors. According to a report by the National Electrical Manufacturers Association (NEMA), metal trays can support substantial loads, making them ideal for industrial applications. However, their weight can be a drawback, leading to higher installation and transportation costs.

On the other hand, fiberglass cable trays offer a lightweight alternative that is resistant to corrosion, which is particularly advantageous in harsh environments. A study published by the International Society of Automation (ISA) indicates that fiberglass trays can be up to 75% lighter than metal options, easing the installation process. However, they may not provide the same level of mechanical strength as metal trays and can be more expensive upfront. Each type presents unique benefits and considerations, making it essential for project managers to weigh them carefully based on project-specific needs.

Installation and Maintenance Tips for Different Cable Tray Systems

When selecting the appropriate cable tray system for your project, understanding the installation and maintenance nuances is crucial. According to a report by MarketsandMarkets, the global cable tray market is expected to grow from USD 4.9 billion in 2020 to USD 7.1 billion by 2025, underscoring the increasing emphasis on efficient installation and long-term maintenance in electrical infrastructure. Choosing the right type of cable tray, whether it's ladder, perforated, or solid bottom, directly impacts the ease of installation and the durability of the electrical routing system.

Proper installation techniques can significantly extend the lifespan of cable trays. For instance, it is essential to maintain the recommended spacing between supports, typically no more than 10 feet for ladder trays, to prevent sagging and ensure safety. Additionally, regular inspections are recommended; a study by the National Electrical Contractors Association (NECA) found that 30% of maintenance issues arise from inadequate inspection routines. Keeping cable trays free of debris and ensuring that cables are neatly organized not only enhances safety but also simplifies any necessary repairs or modifications in the future. Implementing these practices can lead to a more efficient operation and reduce overall costs related to system downtimes.

Related Posts

-

Why Lead Sheathed Cable is Essential for Modern Electrical Applications

-

7 Best Practices for Using Wire Mesh Cable Tray in Modern Data Centers

-

Comprehensive Guide to Selecting the Best Flexible Cable Conduit for Your Project

-

Understanding the Different Types of Electrical Cable Connectors for Your Projects

-

Top Strategies for Sourcing Shielded Power Cable in Global Markets

-

Exploring Cooker Cable Innovations at the 2025 China Import and Export Fair

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•