A partner you can trust

2025 Top Underground Cable Conduit Types: What You Need to Know

As the demand for reliable and efficient electrical infrastructure continues to grow, understanding the various types of underground cable conduit is becoming increasingly vital for professionals in the field. According to industry expert John Smith, a renowned electrical engineer with over 20 years of experience, "Selecting the right underground cable conduit type not only enhances safety but also prolongs the lifespan of electrical systems." This statement highlights the importance of making informed choices when it comes to underground installations.

In the upcoming years, specifically by 2025, the market for underground cable conduits is expected to evolve significantly, driven by technological advancements and changing regulatory standards. Understanding the characteristics, benefits, and appropriate applications of different conduit materials—such as PVC, HDPE, and metal conduits—will be essential for engineers, contractors, and project managers.

By delving into the top types of underground cable conduits available in 2025, this article seeks to provide valuable insights and guidance for professionals aiming to enhance their project's efficiency and safety. Whether you are involved in new installations or upgrades, being well-informed about the best practices and options in underground cable conduit will undoubtedly lead to better outcomes.

Overview of Underground Cable Conduit Types in 2025

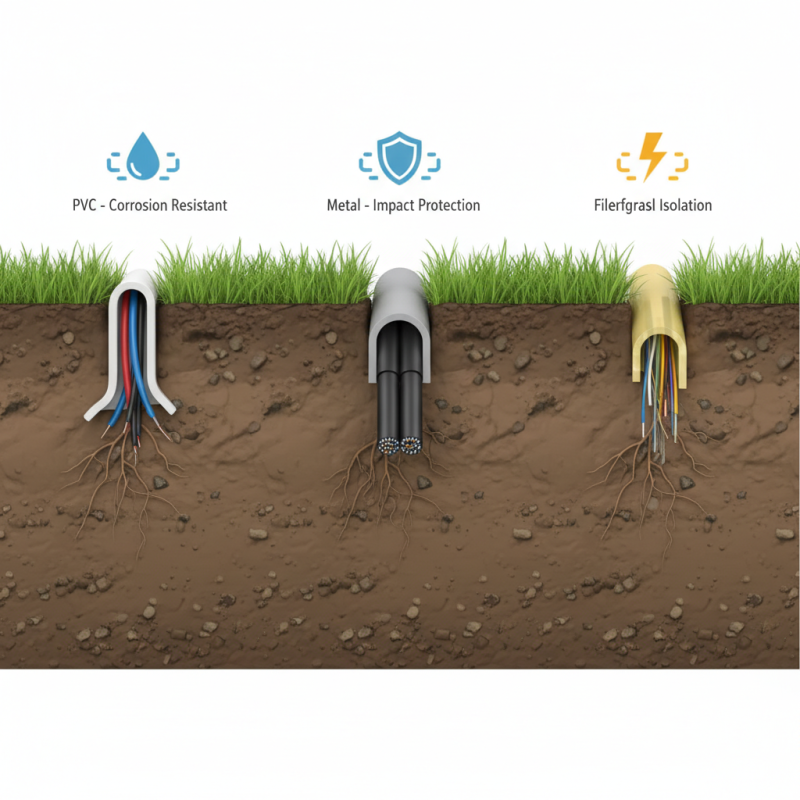

In 2025, the landscape of underground cable conduits is evolving, driven by advancements in technology and increasing safety standards. The primary types of conduits include PVC, Rigid Steel, and Fiber Reinforced Polymer (FRP), each offering unique benefits suited for various environmental conditions and applications. According to a recent industry report by the International Electrical and Electronics Engineers (IEEE), the global demand for underground conduits is expected to grow by 5.2% annually, reflecting the ongoing shift towards more efficient and safe underground installations.

PVC conduits remain popular due to their lightweight characteristics and resistance to corrosion, making them ideal for residential and commercial electrical installations. Rigid Steel conduits provide superior mechanical protection and are commonly used in industrial settings where durability is a crucial factor. In contrast, fiber-reinforced polymer conduits are gaining traction for their excellent resistance to chemicals and moisture, positioning them as a favored option for sectors where environmental factors could compromise cable integrity. The 2025 conduit landscape reflects an urgent focus on sustainability and efficiency, as highlighted in a report from the Global Conduit Products Association, which indicates a significant shift towards eco-friendly materials in the conduit manufacturing process.

With innovations such as smart conduits equipped with monitoring sensors, the future of underground cable conduits is geared towards enhancing infrastructure resilience while ensuring safety. The integration of smart technologies is projected to introduce a new era of real-time data monitoring, allowing for proactive maintenance and reduced overhead costs. As industries strive for greater sustainability and performance in cable management, understanding these conduit types will be essential for stakeholders involved in planning and execution of underground electrical projects.

Key Factors in Selecting the Right Conduit for Your Project

When selecting the right underground cable conduit for your project, several key factors must be considered to ensure durability, efficiency, and compliance with safety regulations. First and foremost, the material of the conduit plays a critical role. Common materials include PVC, fiberglass, and metal, each offering distinct advantages. For instance, while PVC conduits are lightweight and resistant to corrosion, metal conduits provide superior protection against physical impacts and are often preferred in applications where electrical grounding is crucial.

Another important factor is the conduit’s size and capacity. It’s essential to choose a conduit that not only accommodates the current cables but also allows for future expansions. Overcrowding conduits can lead to overheating and electrical failures, so planning for additional capacity is a proactive approach. Additionally, understanding environmental conditions, such as soil type and moisture levels, can influence the selection process, as some materials perform better in specific environments. Ultimately, thorough assessment of these key factors will guide you in choosing the most suitable conduit for ensuring the longevity and safety of your underground wiring systems.

Comparative Analysis of Material Options for Cable Conduits

When considering underground cable conduits, the choice of material is crucial for ensuring durability and performance. The two most commonly used materials are PVC and fiberglass. PVC conduits are lightweight, cost-effective, and resistant to moisture and chemicals, making them a popular choice for a variety of applications. However, they may not withstand extreme temperature fluctuations as well as other materials. On the other hand, fiberglass conduits offer superior strength and durability, ideal for harsh environments. They can handle larger temperature variations and have excellent resistance to corrosion, making them suitable for long-term underground installations.

Tips: When selecting the right material for your cable conduit, consider factors such as environmental conditions, the nature of the cables being used, and budget constraints. It's also beneficial to consult with professionals who can provide insights on local regulations and safety standards that may affect your choice.

Additionally, emerging materials such as HDPE (High-Density Polyethylene) are gaining popularity due to their flexibility and resistance to impact and chemicals. HDPE conduits can be particularly useful in areas prone to ground movement, as they can withstand shifting terrain. When comparing material options, ensure that you also factor in installation methods, accessibility for repairs, and long-term maintenance needs to make the most informed decision.

Installation Techniques for Different Types of Underground Conduits

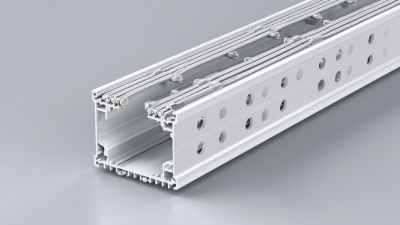

When it comes to installing underground cable conduits, the choice of type greatly influences the techniques used. For rigid conduits, such as PVC or rigid metal conduits, installation typically involves digging trenches that accommodate the depth and width required for the conduit. Proper alignment is crucial, as any mismatches can lead to issues such as cable damage or improper load distribution. The ends of the conduits must be properly sealed and fitted to prevent moisture intrusion, which can degrade the cabling over time.

In contrast, flexible conduits offer easier handling and installation in tight spaces or around obstacles. Techniques for installing flexible conduits often involve bending and looping to navigate existing structures, which can save both time and resources. These conduits usually require less restrictive trenching, as they can be laid in shallow beds or directly buried. However, proper securing with straps or brackets is essential to avoid movement and ensure stability. Regardless of the type chosen, adhering to local codes and regulations during installation is paramount to ensure safety and durability.

Future Trends in Underground Cable Conduit Design and Technology

As the demand for reliable and efficient underground cable systems continues to grow, the trends in conduit design and technology are evolving to meet the challenges of modern infrastructure. A report from the International Electrotechnical Commission (IEC) notes that the global underground cable market is projected to reach $52 billion by 2025, driven primarily by the increasing requirement for enhanced safety and reduced environmental impact in urban areas.

Among the notable trends is the integration of smart technology into conduit systems. Advanced monitoring solutions, including IoT sensors, are being developed to provide real-time data on the condition of underground cables. This proactive approach not only minimizes downtime but also enhances maintenance strategies, as reported by the IEEE Power and Energy Society. Additionally, environmentally friendly materials are gaining traction, with developments in recycled composites indicating a shift towards sustainability in design. A study by MarketsandMarkets highlights that the use of such materials can reduce the environmental footprint of conduit systems by up to 30%, showcasing the industry's commitment to innovation and responsible practices.

Furthermore, the design of underground conduits is becoming more modular and scalable, which allows for easier installation and future upgrades. As cities expand and technological needs evolve, modular systems enable utilities to adapt swiftly to changing requirements without major disruptions. The adoption of trenchless technology in installation processes is also on the rise, improving efficiency and minimizing surface impact. The overall focus is clearly on creating smarter, more adaptable underground cable conduit solutions that not only enhance operational efficiency but also prioritize environmental sustainability.

2025 Top Underground Cable Conduit Types

This chart illustrates the projected market share of various underground cable conduit types by 2025. The data reflects the growing trends in cable conduit design, focusing on materials, durability, and efficiency.

Related Posts

-

How to Choose the Right Flexible Cable Conduit for Optimal Electrical Safety

-

Top Electrical Cable Tray Types: Which One is Right for Your Project?

-

10 Best Micro Coaxial Cables for Unmatched Performance in 2023

-

Discover the Benefits of Using Flat Power Cables for Hassle Free Connectivity

-

How to Choose the Best Flat Power Cable for Your Needs

-

Essential Guide to Choosing the Right Cable Conduit for Your Electrical Projects

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•