A partner you can trust

What Are the Different Types of Electrical Cable Connectors and Their Uses?

In today's technologically driven world, the importance of electrical cable connectors cannot be overstated. With the continuous advancement in electrical and electronic systems, understanding the various electrical cable connectors types is essential for professionals in the industry. According to a report by Market Research Future, the global demand for electrical connectors is expected to reach $94.50 billion by 2025, signifying the growing importance of reliable connectivity solutions across various sectors, including telecommunications, automotive, and industrial applications.

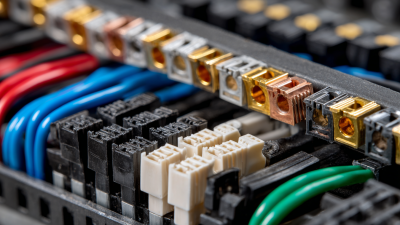

Electrical cable connectors serve as the backbone of efficient and safe electrical connections, ensuring that power and data transfer seamlessly within devices and networks. The market is characterized by a diverse array of electrical cable connectors types, including but not limited to, circular connectors, rectangular connectors, and modular connectors. These connectors vary in design, application, and functionality, making it crucial for users to select the appropriate type based on their specific needs. As technology evolves, so do the complexities of electrical connections, underscoring the necessity for professionals to stay informed about the latest advancements and trends in electrical cable connectors. Understanding these components can lead to enhanced performance, increased safety, and greater efficiency in electrical systems.

Types of Electrical Cable Connectors: An Overview

Electrical cable connectors are crucial components in various electrical systems, enabling secure connections between cables and devices. There are several types of connectors, each designed for specific applications. The three primary categories include terminal blocks, plug-and-socket connectors, and specialty connectors. According to a report from the International Electrotechnical Commission (IEC), the demand for electrical connectors is projected to grow at a compound annual growth rate (CAGR) of 6.0% through 2027, primarily driven by advancements in the automotive and telecommunications sectors.

Terminal blocks are widely used in industrial settings. They provide a reliable way to connect multiple wires with a common point, facilitating easy modifications and maintenance. Plug-and-socket connectors, on the other hand, are essential in both consumer electronics and heavy machinery due to their ease of use and the variety of configurations available. Furthermore, specialty connectors, such as coaxial connectors, serve specific purposes such as video/audio transmission and networking. The growth of IoT devices and the push for smart infrastructure are expanding the market for these connectors, highlighting their vital role in modern electrical systems.

Types of Electrical Cable Connectors and Their Uses

Common Uses of Electrical Cable Connectors in Various Industries

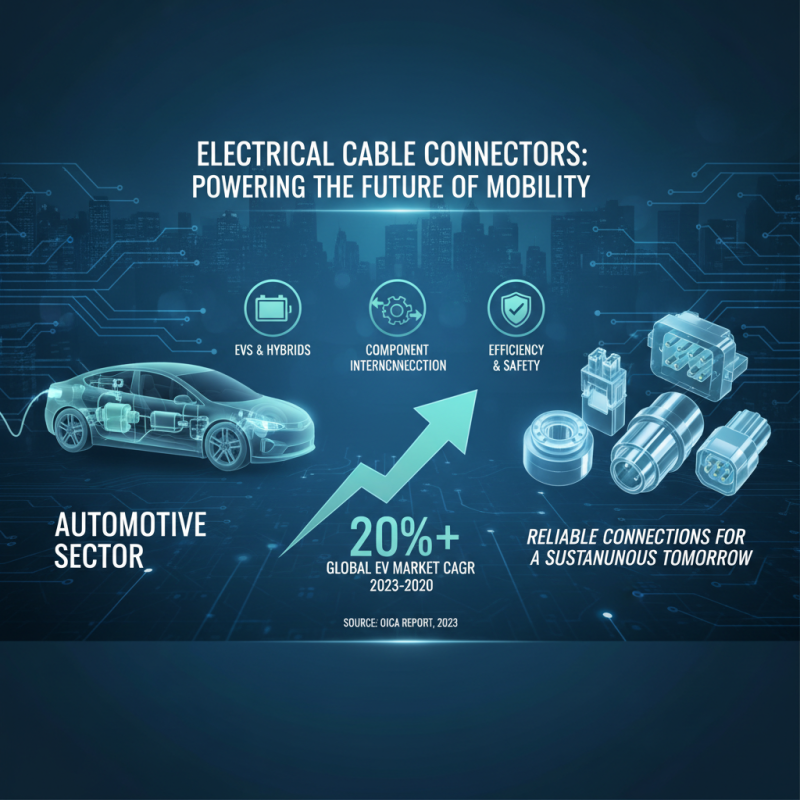

Electrical cable connectors play a crucial role across various industries, facilitating the seamless transmission of electrical energy and data. In the automotive sector, for instance, connectors are essential for connecting components within vehicles, especially with the rise of electric and hybrid vehicles. According to a report by the International Organization of Motor Vehicle Manufacturers (OICA), the global electric vehicle market is expected to grow at a CAGR of over 20% from 2023 to 2030. This growth necessitates robust and reliable electrical cable connectors to ensure the efficiency and safety of the vehicles.

In the telecommunications industry, electrical cable connectors enable the high-speed transfer of data. With the increasing demand for faster internet and mobile connectivity, the global telecom market is projected to reach $1.6 trillion by 2027, according to a report by Fortune Business Insights. Connectors such as RJ45 and fiber optic connectors are integral in establishing high-bandwidth connections, enabling services like 5G, cloud computing, and IoT applications. The reliability and efficiency of these connectors directly impact the performance of communication networks, underscoring their importance in modern infrastructure.

Moreover, in the renewable energy sector, connectors are vital for solar and wind energy applications. A report from the International Renewable Energy Agency (IRENA) projects that solar power capacity will reach 4,000 GW by 2030, necessitating dependable electrical cable connectors for system integration. These connectors ensure that energy generated from renewable sources can be efficiently transported and utilized, supporting the transition to sustainable energy systems globally.

Detailed Comparison of Connectors: Features and Specifications

Electrical cable connectors come in various types, each designed for specific applications while possessing unique features and specifications. Among the most common types are the wire-to-wire and wire-to-board connectors. Wire-to-wire connectors are primarily used to join two or more wires together, providing a reliable and secure connection for various electrical circuits. These connectors often feature locking mechanisms, ensuring stability and preventing accidental disconnection during operation. On the other hand, wire-to-board connectors connect wires directly to a printed circuit board (PCB), enabling effective communication between electronic components. These connectors are generally compact, supporting high-density arrangements in electronic devices.

When comparing connectors, one must consider factors like current rating, voltage rating, and the number of poles, which dictate their applicability in different scenarios. For instance, connectors with a higher current rating are suitable for applications that require the transmission of larger power loads, while lower-rated connectors suffice for signal transfers. Additionally, the material of the connector plays a crucial role in its durability and performance; metallic connectors typically provide enhanced conductivity compared to plastic variants. Understanding the distinct features and specifications of each type of connector can greatly influence the reliability and efficiency of electrical systems, ensuring optimal performance in any setting.

Choosing the Right Connector for Your Electrical Application

Choosing the right connector for your electrical application is crucial to ensuring safe and efficient operation. The electrical connector market is diversified, with a variety of types available including screw connectors, push-in connectors, and modular connectors. According to a report by Mordor Intelligence, the global electrical connectors market is anticipated to reach over $85 billion by 2027, reflecting the crucial role these components play in virtually every industry from automotive to telecommunications.

When selecting a connector, one must consider the application’s specific requirements such as voltage, current rating, and environmental conditions. For instance, waterproof connectors are essential for outdoor or marine applications to prevent corrosion and moisture damage; whereas high-temperature connectors are necessary for environments subject to heat stress. Additionally, Collins Aerospace indicates that using connectors rated for the intended application can significantly reduce failure rates, thereby enhancing the overall reliability of the system.

Furthermore, compatibility is another important factor. It is essential to ensure that the connector type matches the wire gauges being used and is suitable for the intended electrical load. The National Electrical Manufacturers Association (NEMA) emphasizes that mismatched connections can lead to higher resistances, resulting in overheating and potential equipment failure. Therefore, a thorough understanding of the various types of electrical connectors and their specified uses is paramount to successful project execution and system durability.

Safety Considerations and Best Practices for Connector Use

When working with electrical cable connectors, safety should always be a top priority. Ensuring that connections are secure and properly insulated is essential to prevent electrical shocks or shorts. Before handling any connectors, it is crucial to disconnect the power source to eliminate any risk of injury. Wearing appropriate personal protective equipment, such as gloves and safety goggles, can further enhance safety during the installation and maintenance process.

Additionally, it is important to use connectors that are suitable for the specific application and environment. Different connectors are designed to withstand varying temperatures, humidity levels, and chemical exposure. Following best practices, such as regularly inspecting connectors for wear and tear, helps maintain their integrity and ensures a reliable electrical connection. Using connectors that meet relevant industry standards can also provide an extra layer of safety, reducing the likelihood of malfunction or failure. Properly labeling connectors can further aid in troubleshooting and maintenance, ensuring that any potential issues are addressed promptly and effectively.

What Are the Different Types of Electrical Cable Connectors and Their Uses?

| Connector Type | Description | Common Uses | Safety Considerations |

|---|---|---|---|

| Socket Connector | Allows for easy connection and disconnection of cables. | Home appliances, computer systems. | Ensure connections are secure to prevent overheating. |

| Plug Connector | Connects to a socket to provide power or data. | Electrical devices, chargers. | Avoid using damaged plugs to reduce shock risk. |

| Terminal Block Connector | Provides a secure point for connecting multiple wires. | Wiring in control panels, automotive applications. | Ensure proper insulation to prevent shorts. |

| BNC Connector | Used for coaxial cable connections. | Video surveillance, radio communications. | Ensure a tight fit to avoid signal loss. |

| RJ45 Connector | Connects network cables to devices. | Networking equipment, Ethernet connections. | Keep connectors free from moisture and dust. |

Related Posts

-

Understanding the Different Types of Electrical Cable Connectors for Your Projects

-

Maximize Your Boat's Performance: Choosing the Right Marine Battery Cable for Optimal Efficiency

-

The Ultimate Guide to Choosing the Right Electric Cable for Your Projects

-

Exploring the Benefits of Shielded Power Cable for Enhanced Electrical Performance

-

Emerging Trends in Electric Cable Industry Insights from China Import and Export Data at the 2025 Canton Fair

-

Discover the Benefits of Using Flat Power Cables for Hassle Free Connectivity

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•