A partner you can trust

Understanding the Different Types of Electrical Cable Connectors for Your Projects

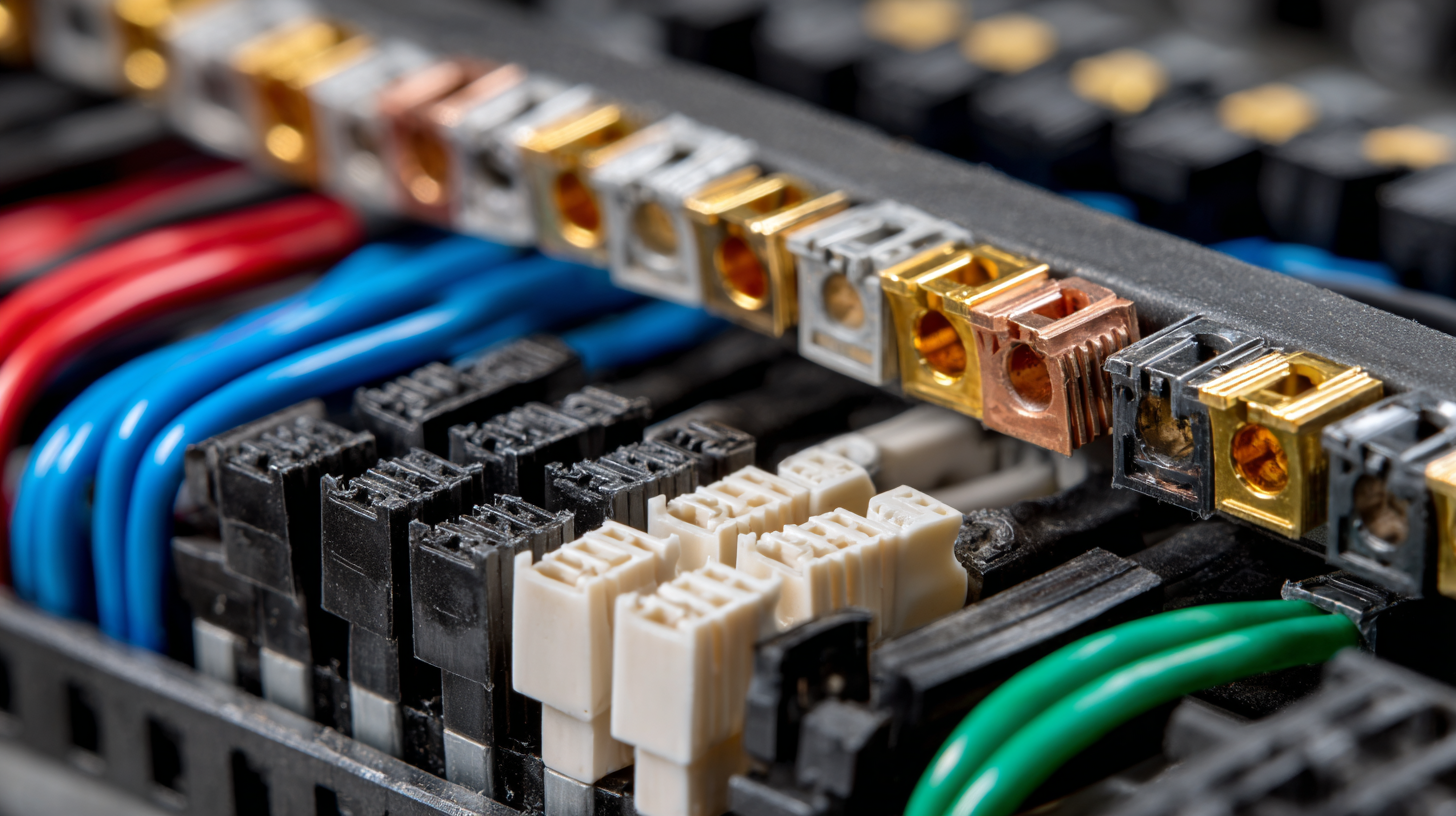

In the realm of electrical engineering, the understanding of electrical cable connectors types is paramount for the successful execution of various projects. According to a recent market research report by Grand View Research, the global market for electrical connectors is projected to reach USD 104.3 billion by 2025, driven by the increasing demand for reliable electrical connections across multiple industries, including automotive, telecommunications, and consumer electronics. As projects become more sophisticated and the demand for efficient and safe electrical installations rises, selecting the appropriate connector type is essential. This guide will delve into the different types of electrical cable connectors, providing insights into their applications, advantages, and suitability for various projects, thus equipping professionals and enthusiasts alike with the knowledge to make informed decisions in their electrical endeavors.

Types of Electrical Cable Connectors: A Comprehensive Overview

When embarking on any electrical project, understanding the various types of electrical cable connectors is essential. These connectors can significantly impact the performance and safety of your installations. A report by MarketsandMarkets indicates that the global electrical connectors market is expected to reach $95.31 billion by 2026, reflecting the growing importance of these components in modern applications. Connector types such as terminal blocks, modular jacks, and USB connectors each serve different purposes, from basic power transfer to advanced data communication.

When embarking on any electrical project, understanding the various types of electrical cable connectors is essential. These connectors can significantly impact the performance and safety of your installations. A report by MarketsandMarkets indicates that the global electrical connectors market is expected to reach $95.31 billion by 2026, reflecting the growing importance of these components in modern applications. Connector types such as terminal blocks, modular jacks, and USB connectors each serve different purposes, from basic power transfer to advanced data communication.

Tips: When selecting a connector, it's crucial to consider factors like current rating, voltage rating, and environmental conditions. For example, connectors used in outdoor applications should be rated for moisture and temperature extremes.

Moreover, understanding the specifications of each connector type allows for better equipment compatibility and user safety. For instance, a study by ResearchAndMarkets highlights that improper connector selection can lead to significant energy losses, potentially reaching up to 20% in some scenarios. With the right choices, not only can efficiency be improved, but longevity of the system can also be enhanced.

Tips: Always ensure connectors meet industry standards to guarantee reliability and safety in your projects.

Choosing the Right Connector for Your Specific Project Needs

When embarking on a project that involves electrical connections, selecting the right connector is crucial for ensuring functionality, safety, and longevity. Different projects may require specific types of connectors, depending on the voltage, environment, and the materials involved. For instance, choosing between a simple butt connector for low-voltage applications or a sealing connector for outdoor use can significantly impact the durability and reliability of your electrical system.

Tips: Always consider the environment—if the connectors will be exposed to moisture or dust, opt for those with a higher IP (Ingress Protection) rating. Additionally, it’s essential to assess the gauge of the wire that will accompany the connector to ensure compatibility, as mismatched sizes can lead to overheating or failure.

Moreover, connectors differ in their ease of installation and maintenance. If you’re working on a project that requires frequent disconnections, take a look at connectors designed for quick release, such as modular connectors. These can save you time and reduce wear and tear on your connection points over the life of your installation.

Tips: Research the specific types of connectors suited for your project; manufacturers often provide detailed guidelines that can help you make the best choice based on application requirements.

Installation Tips for Different Types of Electrical Connectors

When working with electrical cable connectors, proper installation is crucial to ensure safety and functionality. Begin by carefully stripping the wires to the appropriate length, typically about 1/2 inch, without damaging the strands. Use high-quality wire strippers for this task, and avoid excessive force. Once stripped, twist the strands together tightly to prevent fraying, which can lead to poor connections.

Next, make sure to select the right type of connector for your project, whether it’s a butt connector, ring terminal, or splicing connector. Each type serves different purposes and has specific applications. For example, ring terminals are ideal for connecting to a stud or screw, while butt connectors are perfect for joining two wires securely. Always consider the gauge of the wire to prevent overheating and ensure that the connector you choose can accommodate the wire size properly.

Lastly, when installing connectors, use a heat gun or crimping tool as appropriate. For heat-shrink connectors, carefully apply heat until the tubing shrinks tightly around the connection, providing insulation and strain relief. For crimp connectors, use the crimping tool to firmly secure the connection, ensuring a stable electrical path. Double-check connections for tightness and insulation to maintain optimal performance in your electrical projects.

Understanding the Different Types of Electrical Cable Connectors for Your Projects - Installation Tips for Different Types of Electrical Connectors

| Connector Type | Description | Common Uses | Installation Tips |

|---|---|---|---|

| Wire Connectors | These connectors join two or more electrical wires together. | Lighting, appliance wiring, and automotive. | Strip insulation, twist wires, and use the appropriate connector size. |

| Screw Terminal Connectors | Connect wires using screws to secure wire strands. | Electrical panels and junction boxes. | Ensure screws are tight but avoid overtightening to prevent damage. |

| Crimp Connectors | Mechanical connectors that are secured using a crimping tool. | Automotive and audio applications. | Choose the right size connector for the wire gauge to ensure a secure fit. |

| Splice Connectors | Used to connect two wires end-to-end. | Extensions and repairs in wiring. | Use heat shrink tubing for extra protection after splicing. |

| RJ45 Connectors | Network connectors used in Ethernet cables. | Networking and telecommunication. | Follow the T568A or T568B wiring standards for correct pinout. |

Common Mistakes to Avoid When Using Cable Connectors

When working with electrical cable connectors, avoiding common mistakes can save time and enhance safety. One prevalent error is underestimating the connector’s specifications. Always ensure that the connector's amperage and voltage ratings match your project requirements. Using a connector with inadequate ratings can lead to overheating, which poses a fire risk.

Another frequent mistake is improper installation. Ensure the wires are properly stripped and securely attached to the connectors. Loose connections can cause arcing, leading to power loss or equipment damage. It’s crucial to double-check the connections for tightness and polarity before powering up your project.

**Tips:** To prevent these issues, always refer to the manufacturer’s guidelines for both the cable and the connectors. Testing connections with a multimeter can help you verify that they're functioning correctly before finalizing your installation. Lastly, using heat shrink tubing can provide additional insulation and protection against moisture, which further safeguards your connections.

Understanding the Different Types of Electrical Cable Connectors

Maintaining and Troubleshooting Electrical Connectors for Longevity

Maintaining electrical connectors is crucial for ensuring their longevity and optimal performance. Regular inspection is vital; connectors should be checked for signs of corrosion, dirt, or mechanical wear, as these factors can compromise conductivity. Cleaning connectors with appropriate contact cleaner helps remove grime and ensures smooth engagement and disengagement. Additionally, applying a protective lubricant can further reduce the risk of corrosion and ensure better electrical contact.

Troubleshooting faulty connectors involves a systematic approach. Start by checking for loose connections, as these can easily cause intermittent failures. Using a multimeter can help diagnose issues by testing for continuity and ensuring that voltage levels are as expected. If a connector is found to be defective, replacing it promptly is essential to prevent further complications in your electrical system.

By maintaining and routinely troubleshooting connectors, you can enhance their reliability and significantly extend their lifespan, ultimately contributing to the success of your projects.

Related Posts

-

How to Choose the Right Flexible Cable Conduit for Optimal Electrical Safety

-

7 Essential Tips for Choosing the Right Power Extension Cable for Your Needs

-

7 Best Practices for Using Wire Mesh Cable Tray in Modern Data Centers

-

Innovative Uses of Electric Cable Wire in Modern Technology

-

Understanding the Benefits of Using Flexible Cable Conduit in Your Projects

-

Comprehensive Guide to Selecting the Best Flexible Cable Conduit for Your Project

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•