A partner you can trust

Types of Electrical Cable Connectors What to Know?

When discussing electrical cable connectors types, the selection and application are crucial. According to expert John Mitchell, “Choosing the right connector can enhance performance and safety.” In the world of electrical installations, understanding these types can prevent potential hazards.

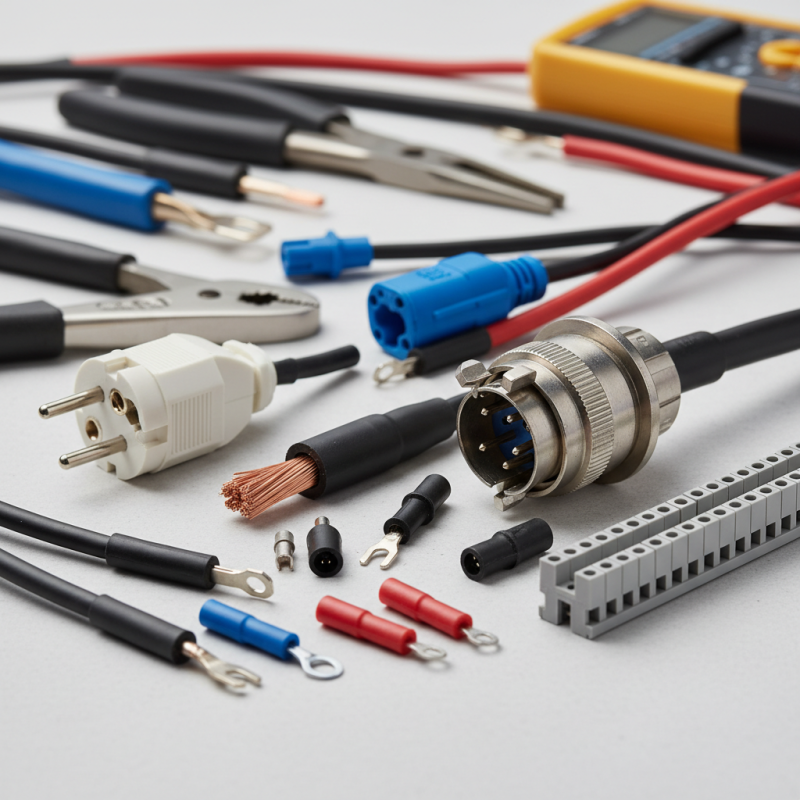

From plugs to terminals, connectors vary widely. Each type serves a specific purpose and carries unique features. For instance, connectors may differ in size, shape, and compatibility with various cables. It's essential to choose connectors that match your project's requirements.

However, the variety can lead to confusion. Many overlook critical aspects like voltage ratings or environmental factors. As John Mitchell notes, “Misjudgments in connector choices often lead to inefficiencies.” Being aware of electrical cable connectors types can guide you in making better decisions and ensure long-lasting connections. Consider how often people choose connectors based on price rather than suitability; this can lead to significant issues down the road. Reflecting on these choices can pave the way for improved outcomes.

Types of Electrical Cable Connectors: An Overview

When it comes to electrical cable connectors, knowing the types is essential. Different connectors serve unique functions. For example, a spade connector allows for an easy and secure connection. On the other hand, a soldered connector offers a permanent option but can be tricky to install. The choice depends on the project demands.

Tips for selecting connectors: Always choose the right gauge for your wires. This ensures safety and efficiency. Color coding can help you identify connectors quickly. Misplacing connectors is common, and it costs time. You might think a connector fits, but it doesn’t. Measure twice before connecting.

Be aware of the environment where connectors will be used. Indoor connectors may not withstand outdoor conditions. Also, check if your connectors are compatible with the cable types. Incompatibility leads to connection problems. Pay attention to the details; small mistakes can cause big issues.

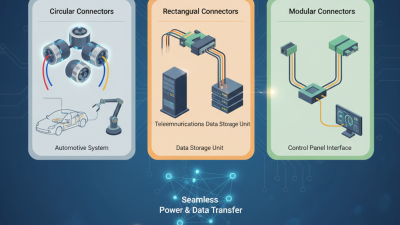

Understanding Different Connector Designs and Their Uses

Electrical cable connectors come in various designs, each suited for specific applications. Understanding these designs is crucial for optimal performance. For instance, a common design is the RJ45 connector, widely used in networking. It enables high-speed data transmission, essential for modern communication setups. According to industry reports, 75% of network failures are linked to poor connections. This highlights the importance of choosing the right connector.

Another vital design is the USB connector. It’s found in numerous devices, from smartphones to printers. The USB-C variant, in particular, is gaining traction due to its versatility. Studies show that the USB connector market is expected to grow by over 20% annually. However, not all connectors deliver equally. Poor-quality connectors can lead to intermittent connections or even device damage.

Connectors also vary in materials and durability. Some use plastic, while others utilize metals for better conductivity. Different environments require different materials. For instance, industrial settings often need rugged connectors to withstand harsh conditions. It's not always obvious which type to choose. Users often overlook details, impacting the overall system performance. Reflections on design choices can lead to better decisions in cable management.

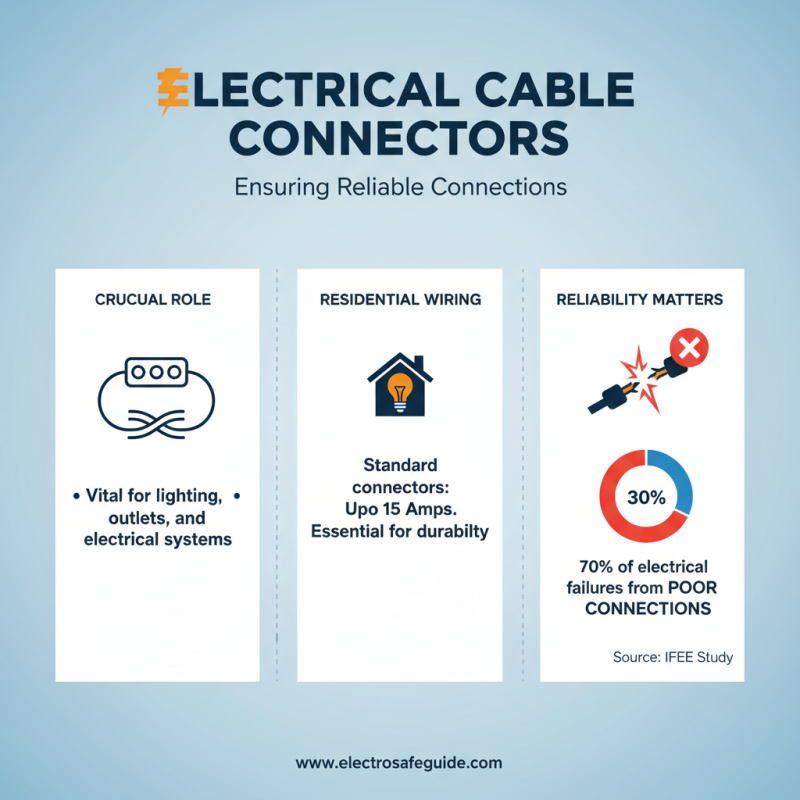

Types of Electrical Cable Connectors Usage Statistics

Key Specifications and Ratings for Electrical Connectors

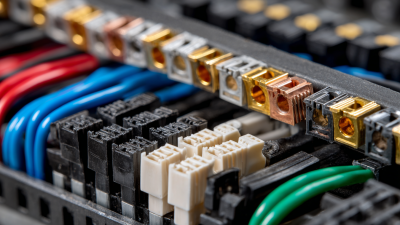

When it comes to electrical connectors, understanding the key specifications and ratings is crucial. Voltage rating defines the maximum voltage a connector can handle safely. If this rating is exceeded, it can lead to catastrophic failures. Another essential specification is the current rating. This indicates how much current the connector can carry without overheating. Choosing a connector with the right ratings is vital for any electrical project.

Furthermore, environmental ratings cannot be overlooked. Connectors may need to withstand moisture, dust, and extreme temperatures. An inadequate rating could cause damage over time. Consider materials used in the connector. Metals like gold offer excellent conductivity but come with high costs. Less expensive options may degrade quicker, leading to poor performance.

The physical size of connectors matters too. In cramped spaces, a bulky connector can be impractical. However, smaller connectors may not always offer the necessary ratings. Hence, it's a balancing act. Remember that mistakes in selection can complicate repair or replacement later. Always double-check specifications and ratings before making a final choice.

Common Applications of Electrical Cable Connectors

Electrical cable connectors play a crucial role in various applications. They ensure reliable connections in electrical systems. For instance, in residential wiring, standard connectors can support currents up to 15 amps. This is vital for lighting and outlets, where durability is necessary. A study by the Institute of Electrical and Electronics Engineers (IEEE) highlights that over 70% of electrical failures stem from poor connections.

In industrial settings, connectors must handle harsher conditions. They often resist dust, moisture, and extreme temperatures. According to recent data, about 35% of equipment failures in factories are traced back to inadequate cable connections. This emphasizes the need for robust designs, suitable for heavy machinery and automation systems. Specialized connectors are often used in these environments to avoid downtime and ensure operational efficiency.

In renewable energy applications, connectors are equally essential. Solar panels and wind turbines rely on them to transmit power efficiently. A report from the International Renewable Energy Agency (IRENA) indicates that inadequate connectors can reduce energy output by 10-15%. This statistic highlights the importance of selecting the right type of connector for each specific application. Understanding these applications helps in choosing the best solution for safety and performance.

Maintenance and Safety Tips for Electrical Connectors

Electrical connectors are crucial for any electrical system. Proper maintenance ensures their reliability. Regular inspection is key. Look for signs of wear or damage. Loose connections can cause overheating. Cracks or corrosion can lead to failure. Cleaning connectors can be tedious, but it’s necessary. Use a soft brush to remove dirt. A cloth with a mild cleaner can also help. Avoid harsh chemicals that can damage the connector.

Safety is paramount when working with electrical connectors. Always turn off the power before doing any maintenance. Use insulated tools to prevent accidental shocks. If you notice any sparking, stop using the connector immediately. It’s better to replace faulty connectors than risk further issues. Keep connectors dry and protected from moisture. This can prevent rust and corrosion. Regular check-ups are a wise practice.

Don't wait for problems to arise. Proactive maintenance can save money in the long run. However, sometimes, issues go unnoticed until it’s too late. Reflect on past experiences with connectors. Could better care have prevented failures? Think about that as you work on your electrical systems.

Related Posts

-

What Are the Different Types of Electrical Cable Connectors and Their Uses?

-

Understanding the Different Types of Electrical Cable Connectors for Your Projects

-

The Ultimate Guide to Sourcing the Best Wire and Cable Products for Your Business

-

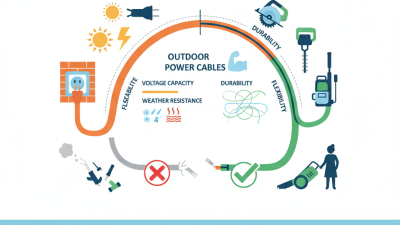

Why Choose the Right Outdoor Power Cable for Your Needs?

-

Ultimate Guide to Choosing the Right Shore Power Cable for Your Business Needs

-

Top 10 Benefits of Using Tray Cable Wire for Reliable Electrical Installations in 2023

Products

Products

LEARN MORE

Current Inventory

Current Inventory

LEARN MORE

Custom Solutions

Custom Solutions

WE CAN HELPLighting Power & Control-Signal Cable

This content is restricted to site members. If you are an existing user, please log in. New users may register … LEARN MORE “Lighting Power & Control-Signal Cable”

LOOKING

FOR HELP?

We are here to help. You can contact us or create an account online to have access to special products, technical specifications and our new online quote tool.

ELECTRO CABLES

9 Riverside Drive

P.O. Box 276

Trenton, Ontario

CANADA K8V 5R5

N.A. Toll Free: 888-ELECTRO

(1-888-353-2876)

World: 613-394-4896

Fax: 613-394-4101

Email: sale@machinecables.com

We manufacture cables that are certified by the Canadian Standards Association (CSA), listed by Underwriters Laboratories and/or listed by Intertek (ETL).

Our quality management system is registered to ISO 9001: 2015. Our team is dedicated to consistently providing quality service and products to our customers.

© 2025 ELECTRO CABLES • SITE BY SNAP 360•